THE ENGINE

A

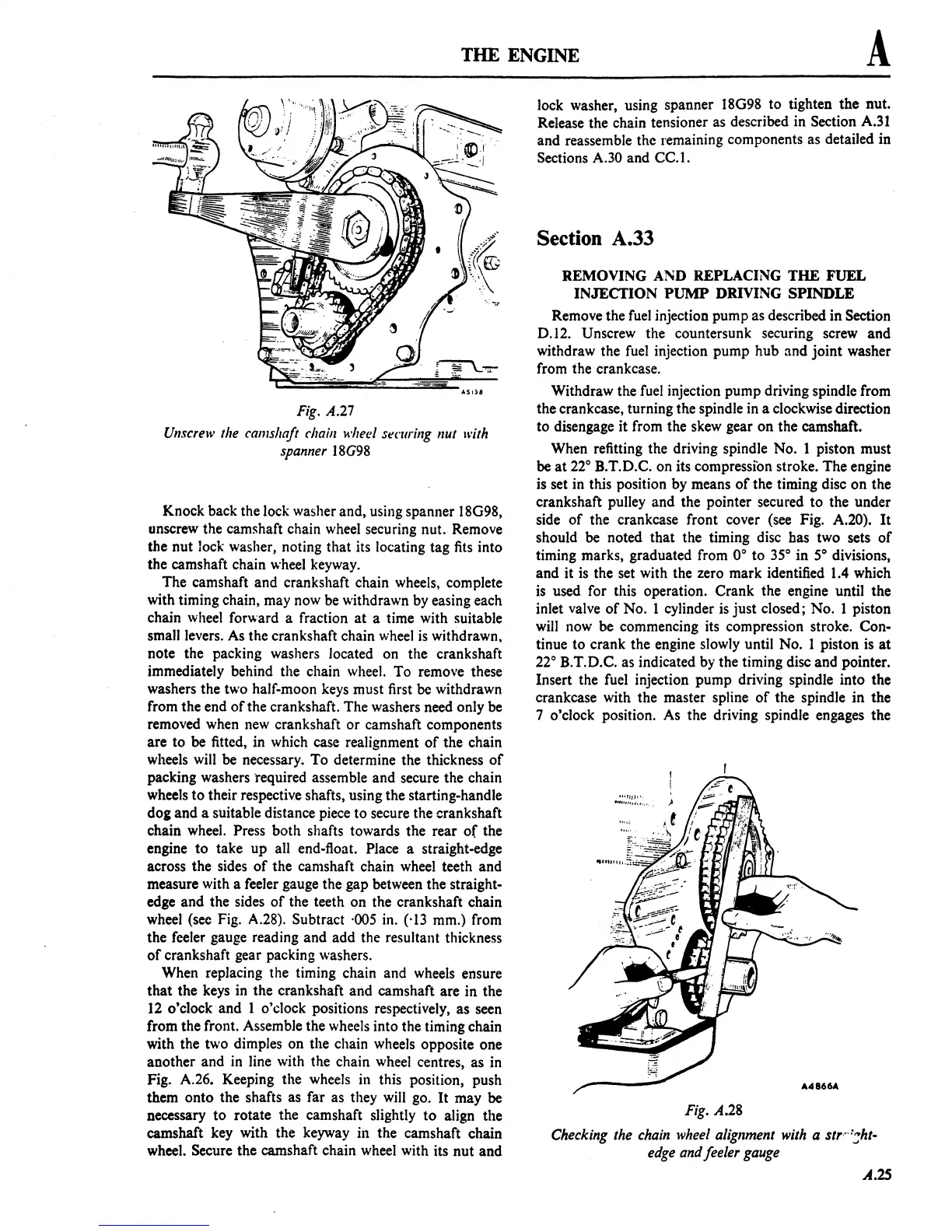

Fig.

A.27

Unscrew

the

camshaft

chain

.....

heel

sl!Cllr;ng

nut

with

spanner

l8G98

Knock back the lock washer and, using spanner l8G98,

unscrew the

camshaft chain wheel securing nut. Remove

the nut lock washer, noting that its locating tag fits into

the camshaft chain wheel keyway.

The camshaft and crankshaft chain wheels, complete

with timing chain, may now be withdrawn by easing each

chain wheel forward a fraction

at

a time with suitable

small levers. As the crankshaft chain wheel

is

withdrawn.

note the packing washers located on the crankshaft

immediately behind the chain wheel. To remove these

washers the two half-moon keys must first be withdrawn

from the end

of

the crankshaft. The washers need only be

removed when new crankshaft

or

camshaft components

are to be fitted, in which case realignment

of

the chain

wheels will be necessary_

To

determine the thickness

of

packing washers "required assemble and secure the chain

wheels

to

their respective shafts, using the starting-handle

dOl and a suitable distance piece

to

secure the crankshaft

chain wheel.

Press both shafts towards the rear

of

the

engine

to

take

up

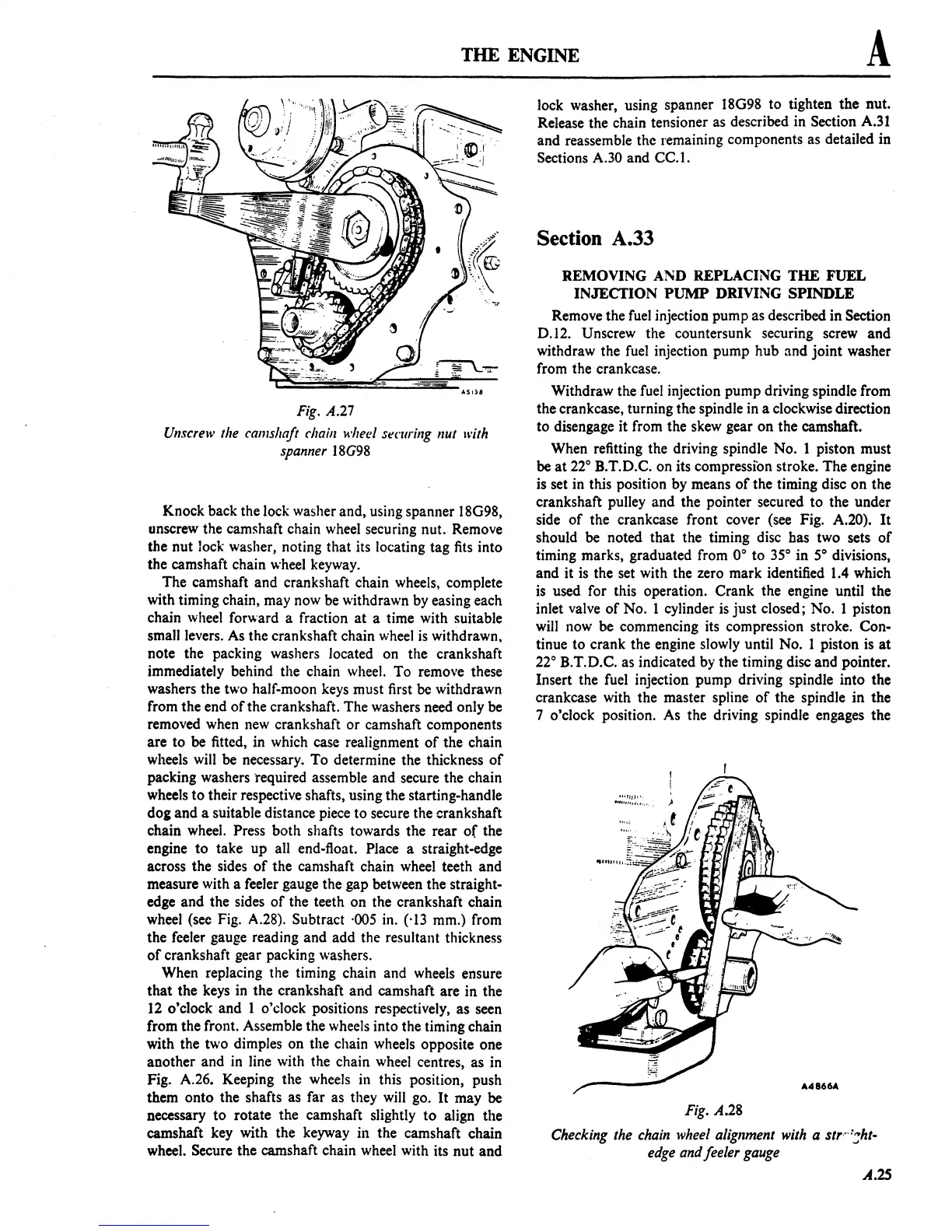

all end-float. Place a straight-edge

across the sides

of

the camshaft chain wheel teeth and

measure with a feeler gauge the gap between the straight-

edge and the sides

of

the teeth on the crankshaft chain

wheel (see Fig. A.28). Subtract

·005 in. (.)3 mm.) from

the feeler gauge reading and add the resultant thickness

of

crankshaft gear packing washers.

When replacing the timing chain and wheels ensure

that

the keys in the crankshaft and camshaft are in the

12

o'clock and 1 o'clock positions respectively,

as

seen

from the front. Assemble the wheels into the timing chain

with the two dimples on the chain wheels opposite one

another and

in

line with the chain wheel centres, as in

Fig. A.26. Keeping the wheels in this position, push

them onto the shafts as far as they will go.

It

may be

necessary

to

rotate the camshaft slightly

to

align the

camshaft key with the keyway ill the camshaft chain

wheel. Secure the camshaft chain wheel with its

nut

and

lock washer, using spanner 18G98

to

tighten the nut.

Release the chain tensioner as described in Section A.31

and reassemble the remaining components as detailed in

Sections A.30 and

CC.l.

Section A.33

REMOVING

AND

REPLACING THE FUEL

INJECTION PUMP DRIVING SPINDLE

Remove the fuel injection pump as described in Section

0.12.

Unscrew the countersunk securing screw and

withdraw the fuel injection pump hub

and

joint

washer

from the crankcase.

Withdraw the fuel injection pump driving spindle from

the crankcase, turning the spindle in a clockwise direction

to

disengage it from the skew gear on the camshaft.

When refitting the driving spindle No. 1 piston must

be

at

22° B.T.D.C. on its compression stroke. The engine

is set in this position by means

of

the timing disc

on

the

crankshaft pulley and the pointer secured

to

the under

side

of

the crankcase front cover (see Fig. A.20).

It

should be noted that the timing disc has two sets

of

timing marks, graduated from 0°

to

35°

in

S°

divisions,

and it is the set with the zero mark identified 1.4 which

is used for this operation. Crank the engine until the

inlet valve

of

No. 1 cylinder is

just

closed; No. 1 piston

will now be commencing its compression stroke. Con-

tinue

to

crank the engine slowly until No. 1 piston is

at

22°

B.T.D.C. as indicated by the timing disc and pointer.

Insert the fuel injection pump driving spindle into the

crankcase with the master spline

of

the spindle

in

the

7 o'clock position. As the driving spindle engages the

Fig.

A.28

Checking

the

chain

wheel

alignment

with

a

str···::;ht-

edge

and feeler

gauge

A.2S

Loading...

Loading...