A

THE ENGINE

--

--

.-

--.

~;'.~'.~~~~.~~~~

.

:-.--.-.-.:.....~:.:-,-,

..

-"-"

..

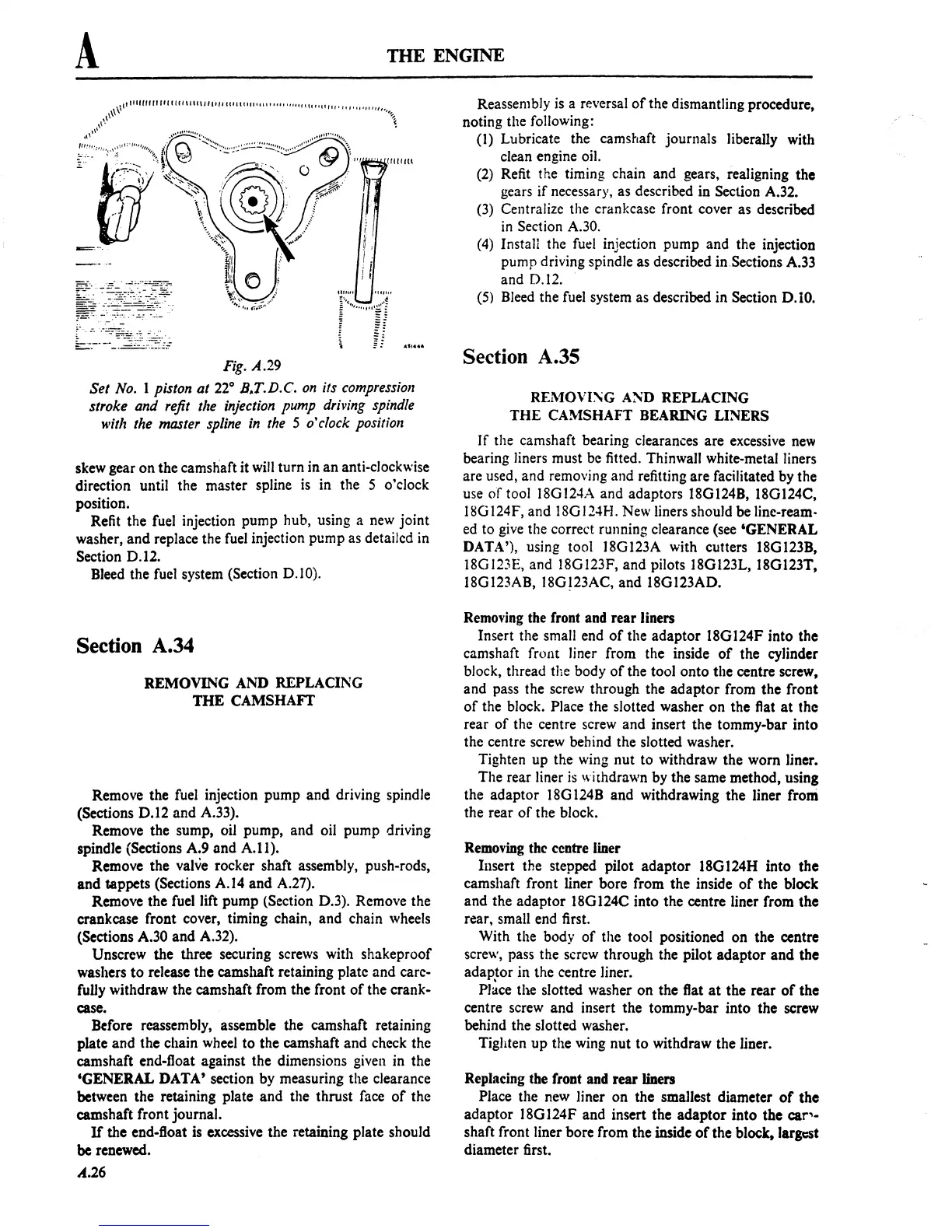

Fig.

A.29

Set No.

I piston at

22°

B.T.D.C.

on

its compression

stroke and refit

the injection pump driving spindle

with the master spline

in

the 5 o'clock position

skew gear

on

the camshaft it

will

turn in

an

anti-clockwise

direction until the master spline

is

in the 5 o'clock

position.

Refit the fuel injection pump hub, using a new joint

washer,

and

replace the

fuel

injection pump

as

detailcd in

Section D.12.

Bleed the fuel system (Section D.I 0).

Section

A.34

REMOVING AND REPLACING

THE

CAMSHAFT

Remove the fuel injection pump and driving spindle

(Sections

D.l2

and A.33).

Remove the sump, oil pump, and oil pump driving

spindle (Sections A.9

and

A.II).

Remove the valve rocker shaft assembly, push-rods,

and

tappets (Sections A.14

and

A.27).

Remove the fuel lift pump (Section D.3). Remove the

crankcase front cover, timing chain, and chain wheels

(Sections A.30 and A.32).

Unscrew the three securing screws with shakeproof

washers

to

release the camshaft retaining plate and carc-

fully withdraw the camshaft from the front

of

the crank-

case.

Before reassembly, assemble the camshaft retaining

plate and the chain wheel to the camshaft and check the

camshaft end-float against the dimensions given in the

'GENERAL DATA' section by measuring the clearance

between the retaining plate and the thrust face

of

the

camshaft front journal.

If

the end-fioat is excessive the retaining plate should

be renewed.

A.26

Reassem

bJy

is

a reversal

of

the dismantling procedure,

noting the following:

(I)

Lubricate the camshaft journals liberally with

clean engine oil.

(2)

Refit the timing chain and gears. realigning the

gears

if

necessary, as described in Section A.32.

(3) Centralize the crankcase front cover as described

in

Section A.30.

(4) Install the fuel injection pump and the injection

pump driving spindle as described

in.Sections A.33

and D.12.

(5) Bleed the fuel system as described in Section D.10.

Section

A.35

REMOVI~G

A~D

REPLACING

THE

CAMSHAFT BEARING LINERS

If

the camshaft bearing clearances are excessive

new

bearing liners must be fitted. Thinwall white-metal liners

are used, and removing and refitting are facilitated by the

use

of

tool 18GI24A and adaptors 18G124B, 18G124C,

UsG

124F, and lSG 124H. New liners should be line-ream-

ed to give the correct running clearance (see 'GENERAL

DATA'), using tool 18Gl23A with cutters 18G123B,

18G123E, and 18G123F. and pilots 18G123L, 18G123T,

I8GI23AB. 18G!23AC. and 18Gl23AD.

Removing the front and rear liners

Insert the small end

of

the adaptor 18GI24F into the

camshaft front liner from the inside

of

the cylinder

block. thread

the body

of

the tool onto the centre screw,

and pass the screw through the

adaptor

from the front

of

the block. Place the slotted washer on the flat

at

the

rear

of

the centre screw and insert the tommy-bar into

the centre screw behind the slotted washer.

Tighten up the wing nut

to

withdraw the worn liner.

The rear liner

is

withdrawn by the same method, using

the adaptor

18G

1248 and withdrawing the liner from

the rear

of

the block.

Removing the centre liner

Insert the stepped pilot

adaptor

18G 124H into the

camshaft front liner bore from the inside

of

the block

and the adaptor 18GI24C into the centre liner from the

rear. small end first.

With the body

of

the tool positioned on the centre

screw, pass the screw through the pilot adaptor

and

the

adaptor in the centre liner.

PI~ce

the slotted washer

on

the flat

at

the rear

of

the

centre screw and insert the tommy-bar into the screw

behind the slotted washer.

Tighten

up

the wing nut to withdraw the liner.

Replacing the front and rear liners

Place the new liner on the smallest diameter

of

the

adaptor ) 8G 124F and insert the

adaptor

into the

car'-

shaft front liner bore from the inside

of

the block, largest

diameter first.

Loading...

Loading...