THE ENGINE

A

9

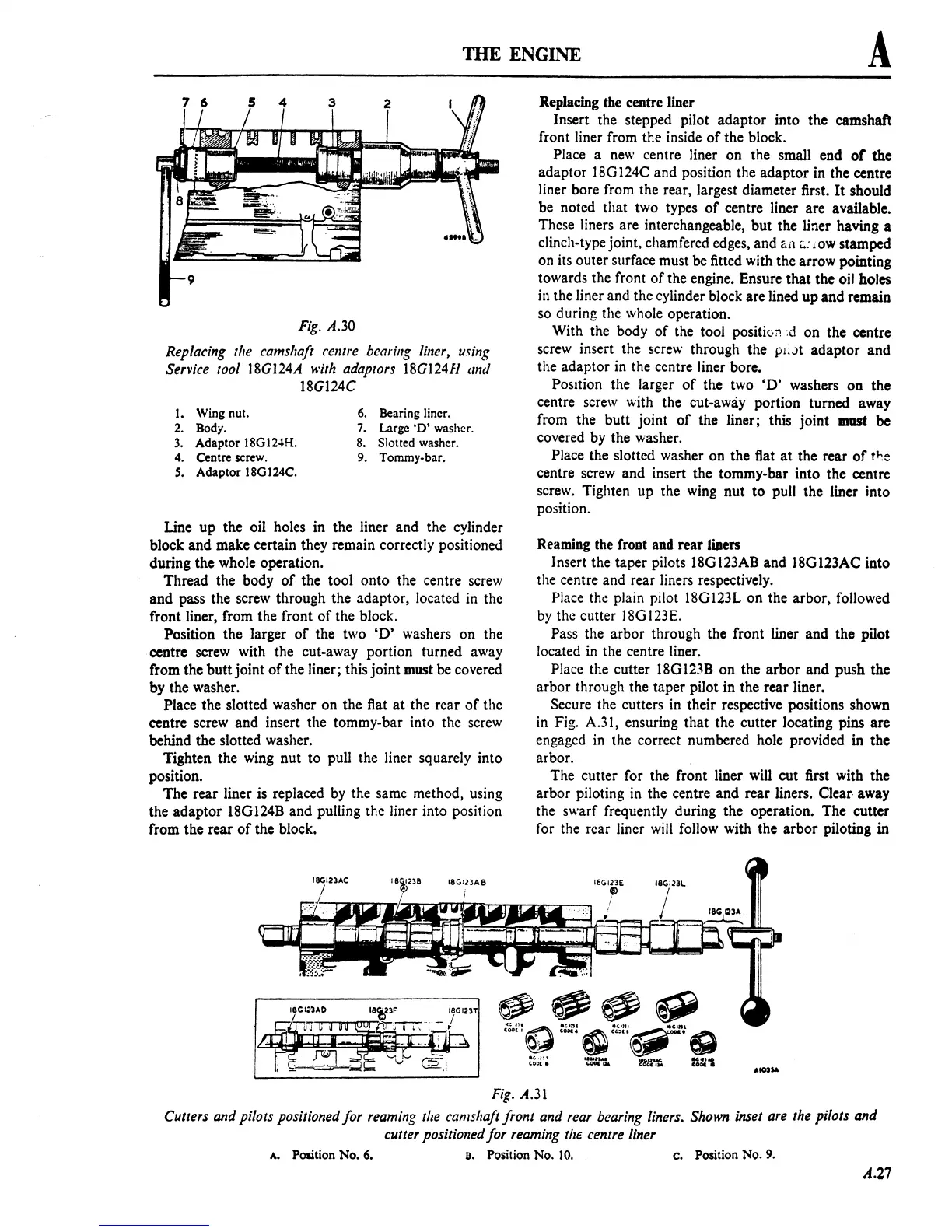

Fig.

A.30

Replacing the camshaft celllre bearing

liner,

using

Service tool

18G124A

with

adaptors 18G124Jl (md

18G124C

I.

Wing nut.

6.

Bearing liner.

2.

Body.

7.

Large

'0'

washer.

3.

Adaptor 18GI2"H.

8.

Slotted washer.

4.

Centre screw. 9. Tommy-bar.

S.

Adaptor 18G124C.

Line

up

the oil holes in the liner and the cylinder

block and make certain they remain correctly positioned

during the whole operation.

Thread the body

of

the tool onto the centre screw

and pass the screw through the adaptor, located in the

front liner, from the front

of

the block.

Position the larger

of

the two

'D'

washers on the

centre screw with the cut-away portion turned away

from the butt joint

of

the liner; this joint must

be

covered

by

the washer.

Place the slotted washer on the flat

at

the rear

of

the

centre screw and insert the tommy-bar into the screw

behind the slotted washer.

Tighten the wing nut to pull the liner squarely into

position.

The rear liner

is

replaced

by

the same method, using

the adaptor 18G124B and pulling the liner into position

from the rear

of

the block.

Replacing the

ccntre liner

Insert the stepped pilot adaptor into the camshaft

front liner from the inside

of

the block.

Place a

new

centre liner on the small end

of

the

adaptor

l8G124C and position the adaptor in the centre

liner bore from the rear, largest diameter first.

It

should

be noted that two types

of

centre liner are available.

These liners are interchangeable, but the liner having a

clinch-type

jOint. chamfered edges, and

~i'I;;':

,ow stamped

on its outer surface must be fitted with the arrow pointing

towards the front

of

the engine. Ensure that the oil holes

in

the liner and the cylinder block are lined up and remain

so during the whole operation.

With the body

of

the tool positivr1:d on the centre

screw insert the screw through the

PI;.)t adaptor and

the adaptor in the centre liner bore.

Position the larger

of

the two

'D'

washers on the

centre screw with the cut-away portion turned away

from the butt joint

of

the liner; this joint

mast

be

covered by the washer.

Place the slotted washer on the flat

at

the rear

of

t~e

centre screw and insert the tommy-bar into the centre

screw. Tighten up the wing nut

to

pull the liner into

position.

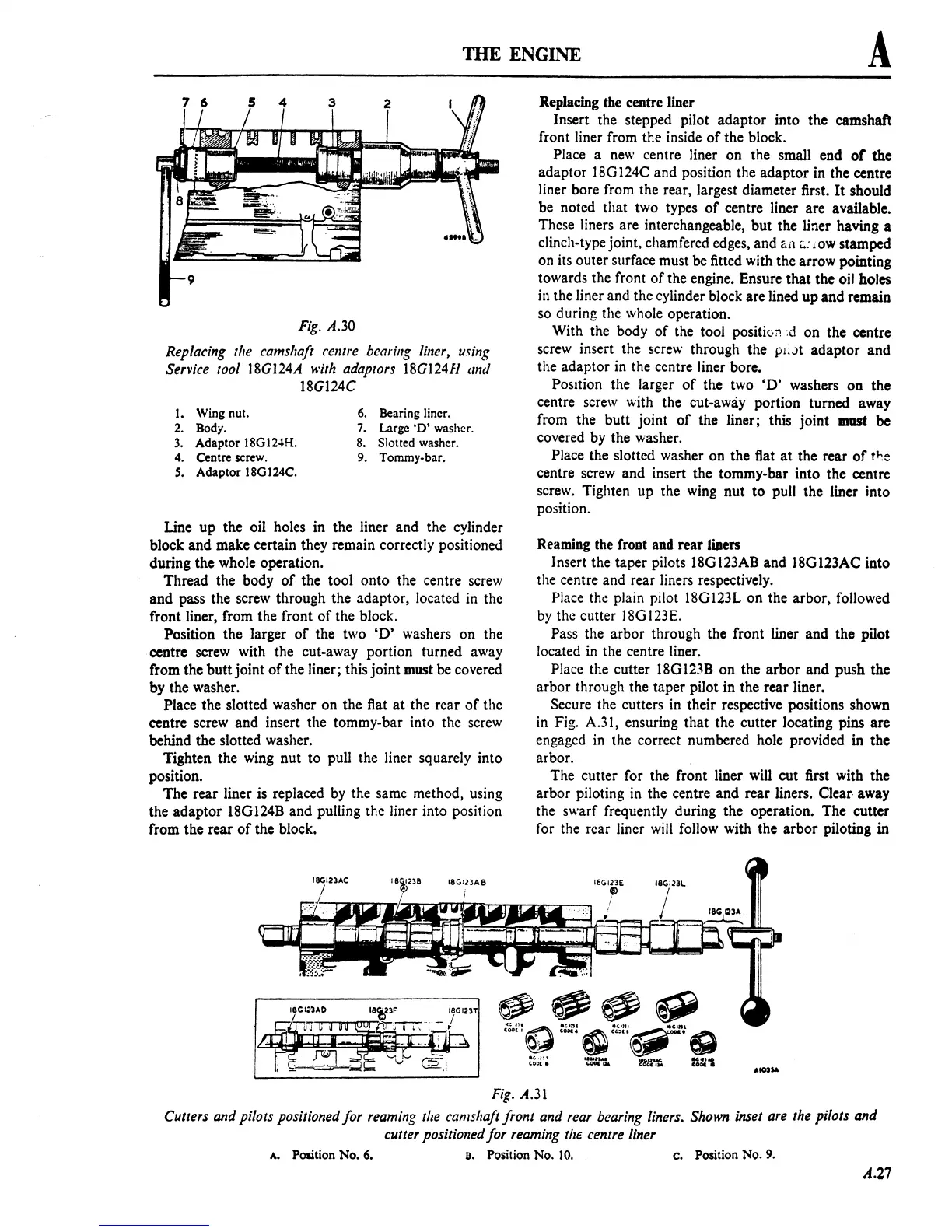

Reaming the front and rear

Iblers

Insert the taper pilots 18G123AB and 18G123AC into

the centre and rear liners respectively.

Place the plain pilot 18G123L on the arbor, followed

by

the cutter l8G123E.

Pass the arbor through the front liner and the pilot

located

in

the centre liner.

Place the cutter 18G123B on the arbor and push

the

arbor through the taper pilot in the rear liner.

Secure the cutters in their respective positions shown

in Fig. A.31, ensuring that the cutter locating pins are

engaged

in

the correct numbered hole provided in the

arbor.

The cutter for the front liner will cut first with the

arbor piloting

in

the centre and rear liners. Clear away

the swarf frequently during the operation. The cutter

for the rear liner

will

follow with the arbor piloting in

Fig.

A.Jl

Cutters and pilots positioned for reaming

the

can/shaft front and

rear

bearing

liners.

Shown

inset

are

the

pilots and

cutter positioned for reaming

the

centre liner

A. Polition

No.6.

D.

Position No.

10.

c.

Position

No.9.

A.27

Loading...

Loading...