A

THE ENGINE

the front and centrc liners. Clear away all the swarf

before the plain pilot

is

allowed

to

enter the front liner.

When the cut in the rear liner

is

finished, free the

cutters and withdraw the arbor.

Reaming the

ceutre liner

Set

up for the second part

of

the operation by inserting

the pilots 18GI23T and 18GI23AD in the front and

rear liners. .

Pass the arbor through the pilot in the front liner and

place the cutter 18G123F on the arbor. Push the arbor

through the centre liner and the pilot located in the rear

liner.

Secure the cutter in the position shown inset in Fig.

A.31, ensuring that the locating pin

of

the cutter engages

thc correct numbered hole in the arbor.

Ream the centre liner, release the cutter, and withdraw

the arbor.

IMPORTANT.-It

is essential that the cutter

Bntes

are kept

dear

of swarf

at

aU

times during

the

cutting

operation,

preferably

witb

air-blast equipment. The

eatter sbould

be

withdrawn from

the

liner half-way

through the cut and the

&Warf

removed

from

the

cutter

and the liner.

Feed the reamer

very

slowly

and keep tbe cutters dry.

The arbor should

be

lightly lubricated before assembling

the cutters and pilots.

•

Section A.36

REMOVING

Arm

REPLACING

THE FLYWHEEL

Remove transmission (Section ).

Disconnect and label wires from starter motor and its

solenoid.

Remove starter motor with solenoid.

Remove wiring bracket from top

of

bellhousing.

Remove nuts securing the rear mounting' brackets to

flexible mount.

Take the weight

off

the rear

of

the engine preferably with a

sling attached

to

the rear lifting bracket.

Do

not jack up

under sump.

Remove capscrews and lockwashers securing bell housing to

back plate.

Remove damper plate.

Remove the 6 nuts and tab washers securing flywheel

to

the

crankshaft and remove flywheel.

When reassembling, crank the engine until the

1.4

zero

mark on the timing disc mounted on the crankshaft pulley

is

in line witb the scribed line on the pointer located on

the under side

of

the crankcase front cover. Nos. 1 and

4 pistons are now

at

T.D.C., and the

flywbeel

should

be

installed with the T.D.C.

1.4

mark

OD

its periphery

at

A.28

the top

of

the flywheel. Tighten the

flywheel

securing

nuts to the figure in the 'GENERAL DATA' section,

using torque wrench

180372.

Install the fuel injection

p~mp

as described in Section

0.12, and bleed the fuel system as described in Section

0.10.

Section A.37

REMOVING AND REPLACING

THE

ENGINE FRONT PLATE

Remove the nuts securing the engine front mounting

brackets to their flexible mounts.

Remove the crankcase front cover,

timiDg

chain, and

timing chain tensioner (Sections

A.30, A.31, and A.32).

Attach the engine by means

of

a sling

to

an overhead

lifting appliance and raise the engine

to

relieve the load

on the engine front mountings.

Unscrew the three securing screws with shakeproof

washers and remove the camshaft retaining plate. Remove

the three set screws with spring washers

and

withdraw the

front plate and joint washer

•

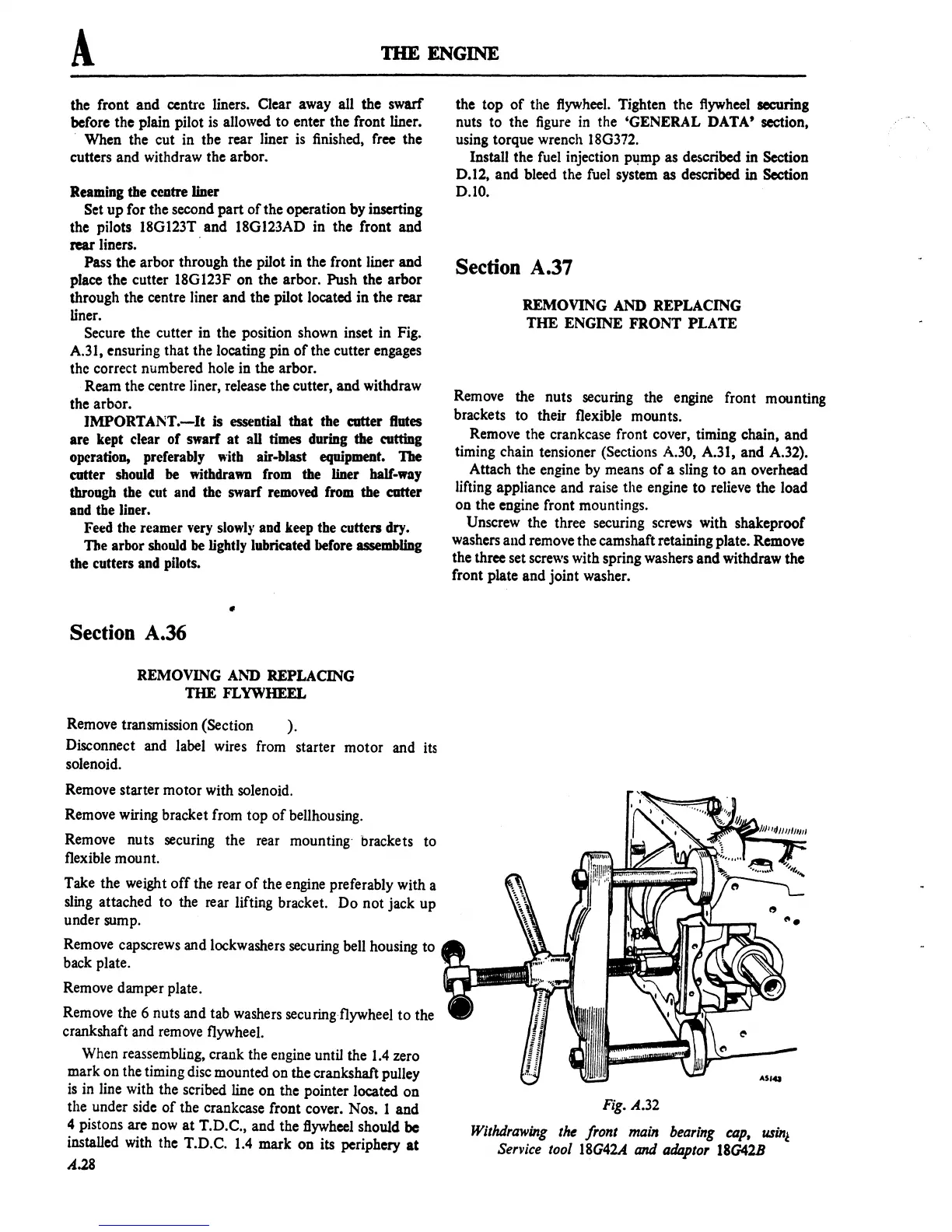

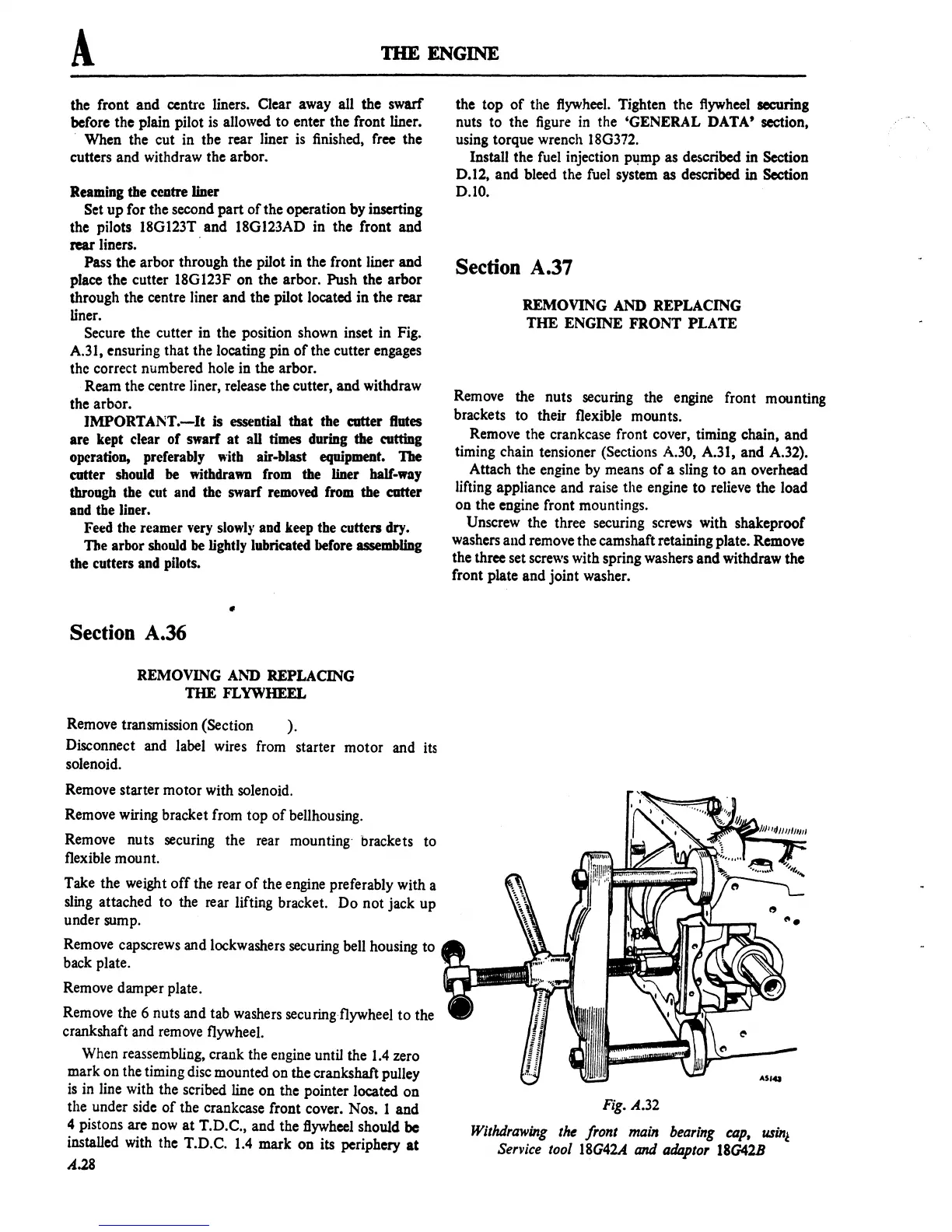

Fig.

A.32

WithdraWing

the front main bearing cap,

usin~

Service tool

18G42A

and

at/4plor 180418

Loading...

Loading...