D

THE FUEL SYSTEM

Section

D.l

DESCRIPTION

The fuel

is

drawn from the supply tank by a mechanical

diaphragm-type lift pump,

which

is

operated by the

engine camshaft.

It

is

imperative that the

fuel

is

absolutely

free from foreign matter, and in addition to the

gauze-

type filters in the fuel lift and injection pumps a filter

of

the renewable paper element type is installed in the

feed

line from the lift pump to the inject jon pump.

The injection pump, which

is

of

the C.A.V. distributor

type, meters and forces fuel under high pressure via

Pintaux injection nozzles into the combustion chambers.

The Pintaux nozzle, which is

of

the pintle type em-

bodying an auxiliary hole to facilitate starting, has been

designed expressly for

use

with the Ricardo Comet V

type combustion chamber which

is

employed in this

engine. The

use

of

these designs ensures easy starting

under arctic conditions, especially when used in

con-

junction with the heater plugs which are fitted.

The accelerator

is

connected to the control lever on

the injection pump, which embodies a governor and

.automatic advance unit, both

of

which are hydraulically

operated.

Section D.2

DESCRIPTION

OF

THE

FUEL LIFT

PUMP

The

fuel

lift pump

is

mounted on the left-hand side

of

the crankcase and

is

operated by an eccentric on the

engine camshaft. A hand priming lever permits pumping

a supply

of

fuel

through the main

fuel

filter to the

injection pump for bleeding the system

of

air whenever

any component has been dismantled or disconnected.

As

the engine camshaft revolves, the eccentric lifts

the pump rocker arm, which moves the pull-rod together

with the diaphragm downwards against the spring'

pressure, thus creating a partial vacuum in the pumping

chamber.

Fuel drawn from the tank enters the sediment cham-

ber and then passes through

the filter gauze and the

suction

valve

into the pumping chamber. On the return

stroke the spring pressure pushes the diaphragm up-

wards, forcing the

fuel

from the pumping chamber

through the delivery valve and port to the main

fuel

filter.

When the main fuel filter

is

full a pressure

is

created

in the pump chamber. This pressure

will

hold the dia-

phragm downwards against the spring pressure, and it

will remain in this position until the main

fuel

filter

requires further

fuel.

The rocker arm operates the con-

necting link, which allows an idling movement

of

the

rocker arm when there

is

no movement

of

the

fuel

pump

diaphragm.

A spring keeps the rocker arm in constant contact

with the eccentric, thus eliminating noise.

D.4

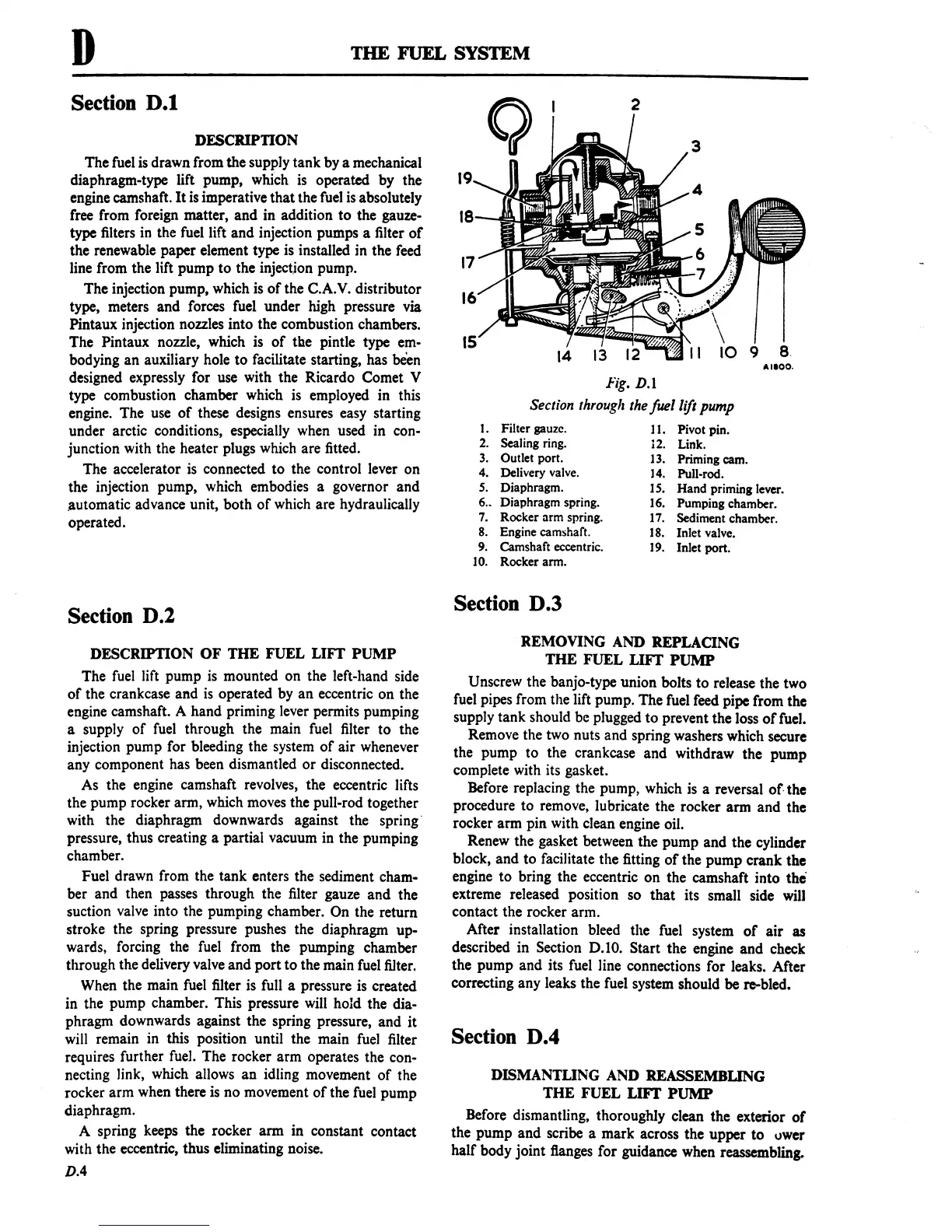

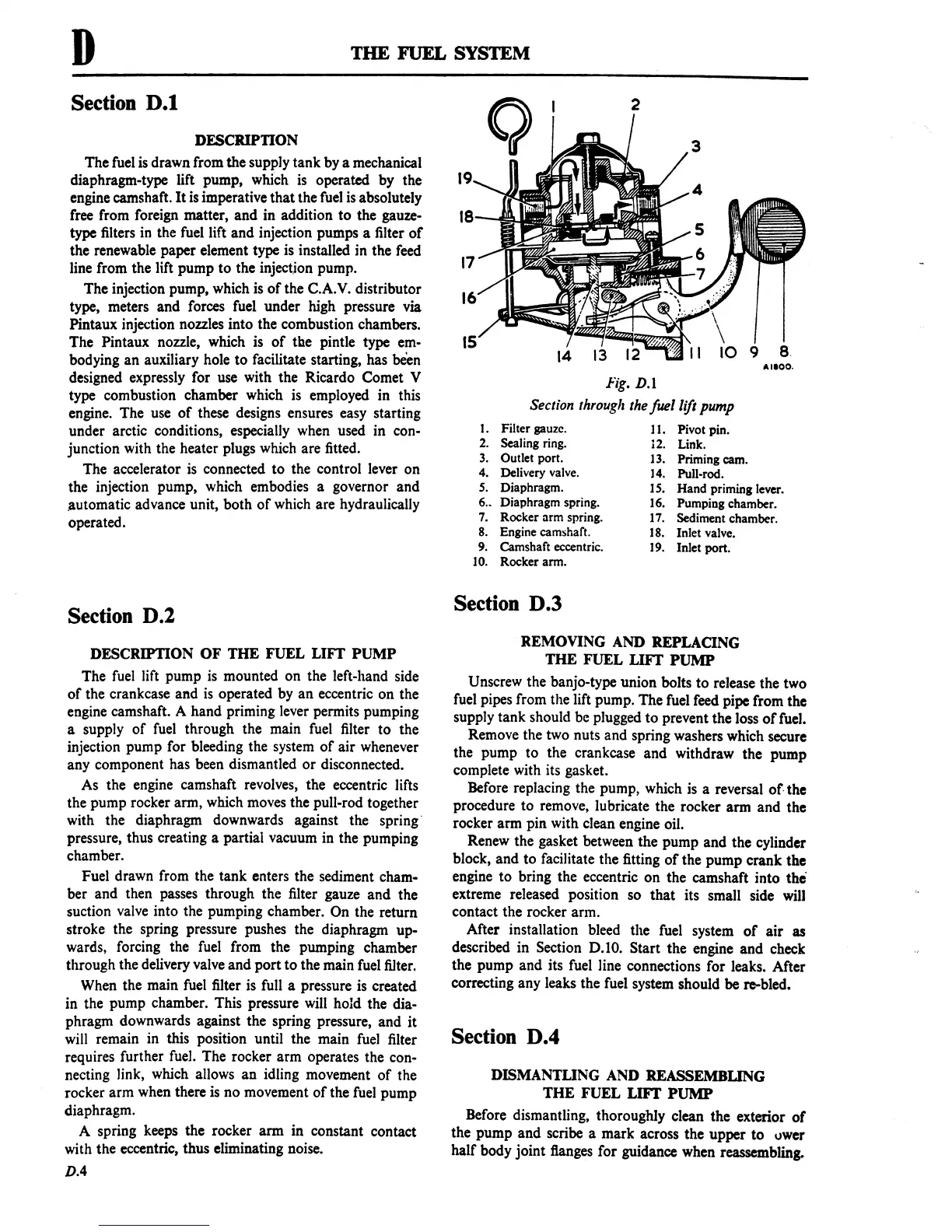

1.

2.

3.

4.

S.

6

..

7.

8.

9.

10.

Fig.

D.l

Section

through

the

fuel lift pump

Filter gauze.

Sealing ring.

Outlet port.

Delivery valve.

Diaphragm.

Diaphragm spring.

Rocker

arm spring.

Engine

camshaft.

Camshaft eccentric.

Rocker arm.

11. Pivot pin.

12. Link.

13.

Priming cam.

14.

Pull-rod.

15.

Hand

priming lever.

16.

Pumping chamber.

17. Sediment chamber.

18. Inlet valve.

19. Inlet port.

Section D.3

REMOVING AND REPLACING

THE FUEL LIFT

PUMP

Unscrew the banjo-type union bolts to release the two

fuel pipes from the lift pump. The fuel feed pipe from the

supply tank should

be

plugged to prevent the loss

of

fuel.

Remove the two nuts and spring washers which secure

the pump to the crankcase and withdraw the pump

complete with its gasket.

Before replacing the pump, which is a reversal

of·

the

procedure to remove, lubricate the rocker arm and the

rocker arm pin with clean engine oil.

Renew the gasket between the pump and the cylinder

block, and to facilitate the fitting

of

the pump crank the

engine to bring the eccentric on the camshaft into

the

extreme released position so that its small side

will

contact the rocker arm.

After installation bleed the fuel system

of

air as

described in Section

0.10. Start the engine and check

the pump and its fuel line connections for leaks. After

correcting any leaks the fuel system should

be

re-bled.

Section D.4

DISMANTLING AND REASSEMBUNG

THE

FUEL LIFT

PUMP

Before dismantling, thoroughly clean the exterior

of

the pump and scribe a mark across the upper to

IJwer

half body joint flanges for guidance when reassembling.

Loading...

Loading...