THE FUEL SYSTEM

D

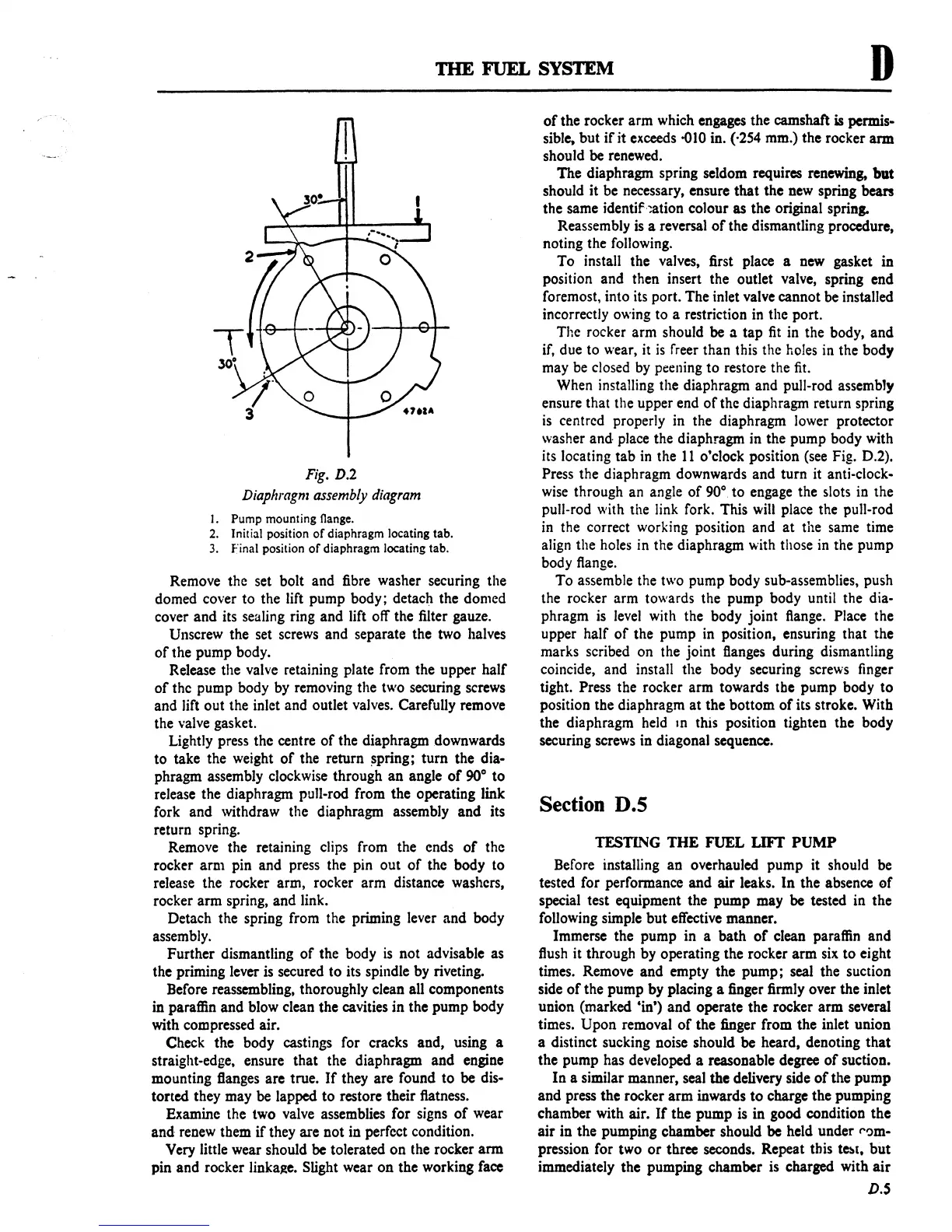

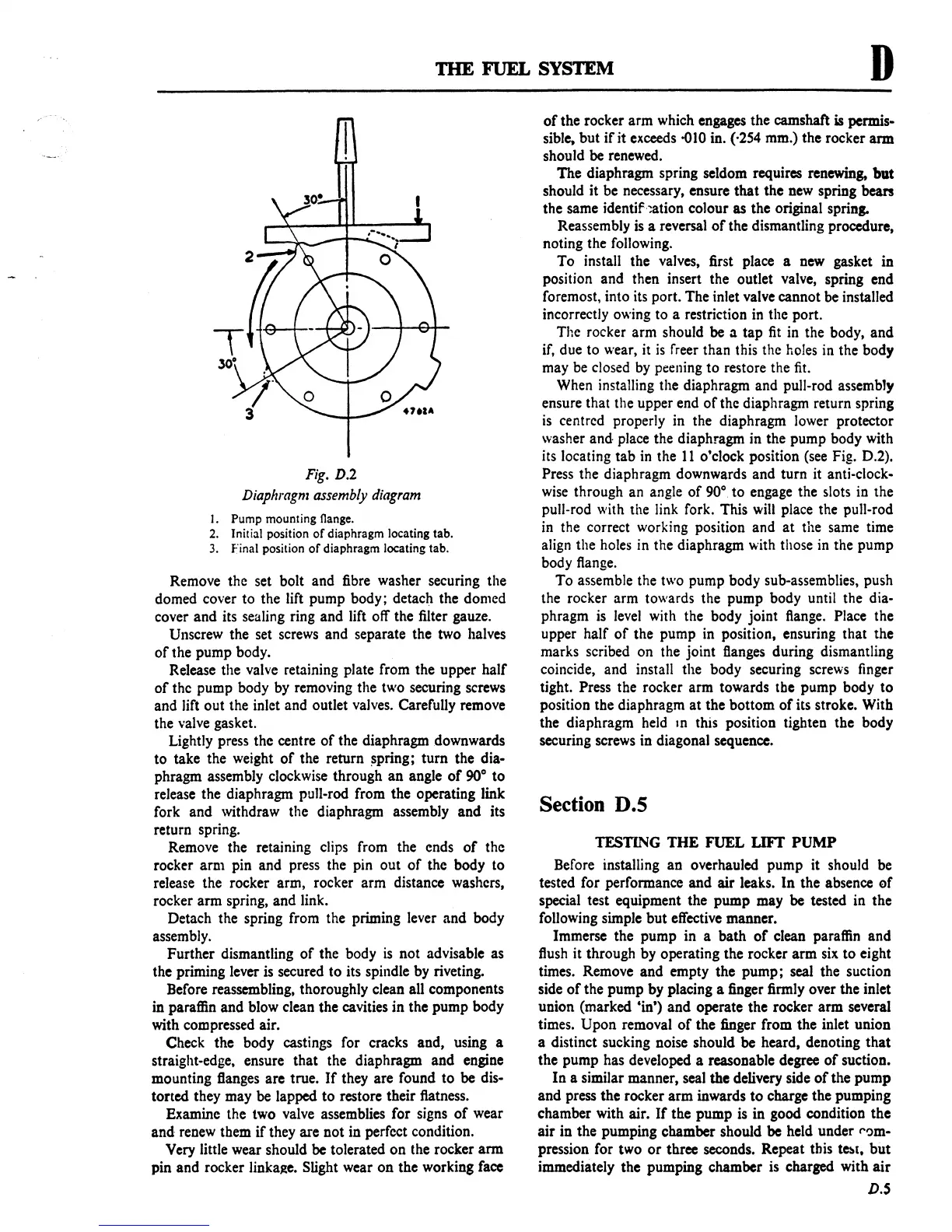

Fig.

D.2

Diaphragm

assembly

diagram

I.

Pump mounting flange.

2.

Initial position

of

diaphragm locating tab.

3.

f'inal position

of

diaphragm locating tab.

Remove the set bolt and fibre washer securing the

domed cover

to

the lift pump body; detach the domed

cover and its sealing ring and lift off the filter gauze.

Unscrew the set screws and separate the two halves

of

the pump body.

Release the valve retaining plate from the upper half

of

the pump body by removing the two securing screws

and lift out the inlet and outlet valves. Carefully remove

the valve gasket.

Lightly press the centre

of

the diaphragm downwards

to

take the weight

of

the return

~pring;

turn the dia-

phragm assembly clockwise through

an

angle

of

90°

to

release the diaphragm pull-rod from the operating link

fork and withdraw the diaphragm assembly and its

return spring.

Remove the retaining clips from the ends

of

the

rocker

arm

pin and press the pin out

of

the body to

release the rocker arm, rocker arm distance washers,

rocker arm spring, and link.

Detach the spring from the priming lever and body

assembly.

Further dismantling

of

the body

is

not advisable as

the priming lever is secured

to

its spindle by riveting.

Before reassembling, thoroughly clean all components

in paraffin and blow clean the cavities

in

the pump body

with compressed air.

Check the body castings for cracks and, using a

straight-edge. ensure that the diaphragm and engine

mounting flanges are true.

If

they are found

to

be dis-

torted they may be lapped

to

restore their flatness.

Examine the two valve assemblies for signs

of

wear

and

renew them

if

they are not in perfect condition.

Very little wear should be tolerated

on

the rocker

arm

pin and rocker linkage. Slight wear

on

the working facc

of

the rocker arm which engages the camshaft

is

permis-

sible. but

if

it exceeds

0010

in. (·254 mm.) the rocker arm

should be renewed.

The diaphragm spring seldom requires renewing, but

should it be necessary, ensure

that

the new spring bean

the same

identif.~tion

colour

as

the original spring.

Reassembly is a reversal

of

the dismantling procedure,

noting the following.

To

install the valves, first place a new gasket in

position and then insert the outlet valve, spring end

foremost, into its port. The inlet valve cannot be installed

incorrectly owing

to

a restriction in the port.

The rocker arm should be a

tap

fit

in the body, and

if, due to wear, it

is

freer than this the holes in the body

may be closed

by

peening

to

restore the

fit.

When installing the diaphragm and pull-rod assembly

ensure that the upper end

of

the diaphragm return spring

is

centred properly in the diaphragm lower protector

washer

and

place the diaphragm in the pump body with

its locating

tab

in

the

11

o'clock position (see Fig. 0.2).

Press the diaphragm downwards and turn it anti-clock-

wise through an angle

of

90°.

to

engage the slots in the

pull-rod with the link fork. This will place the pull-rod

in the correct working position and

at

the same time

align the holes in the diaphragm with those in the pump

body flange.

To

assemble the two pump body sub-assemblies. push

the rocker

arm towards the pump body until the dia-

phragm

is

level with the body joint flange. Place the

upper half

of

the pump

in

position, ensuring that the

marks scribed on the joint flanges during dismantling

coincide, and install the body securing screws finger

tight.

Press the rocker arm towards tbe pump body

to

position the diaphragm

at

the bottom

of

its stroke. With

the diaphragm held

ID

this position tighten the body

securing screws in diagonal sequence.

Section D.S

TESTING

THE

FUEL

LIFT

PUMP

Before installing an overhauled pump it should be

tested for performance and air leaks.

In

the absence

af

special test equipment the pump may be tested in the

following simple

but

effective manner.

Immerse the pump in a bath

of

clean paraffin and

flush it through by operating the rocker

arm

six

to

eight

times. Remove and empty the

pump;

seal the suction

side

of

the pump by placing a finger firmly over the inlet

union (marked 'in') and operate the rocker

arm

several

times.

Upon removal

of

the finger from the inlet union

a distinct sucking noise should be heard, denoting

that

the pump has developed a reasonable degree

of

suction.

In

a similar manner, seal the delivery side

of

the

pump

and press the rocker arm inwards

to

charge the pumping

chamber with air.

If

the pump is in good condition the

air in the pumping chamber should be held under

('~m

pression for two

or

three seconds. Repeat this

t~[,

but

immediately the pumping chamber is charged with

air

D.S

Loading...

Loading...