D

THE FUEL SYSTEM

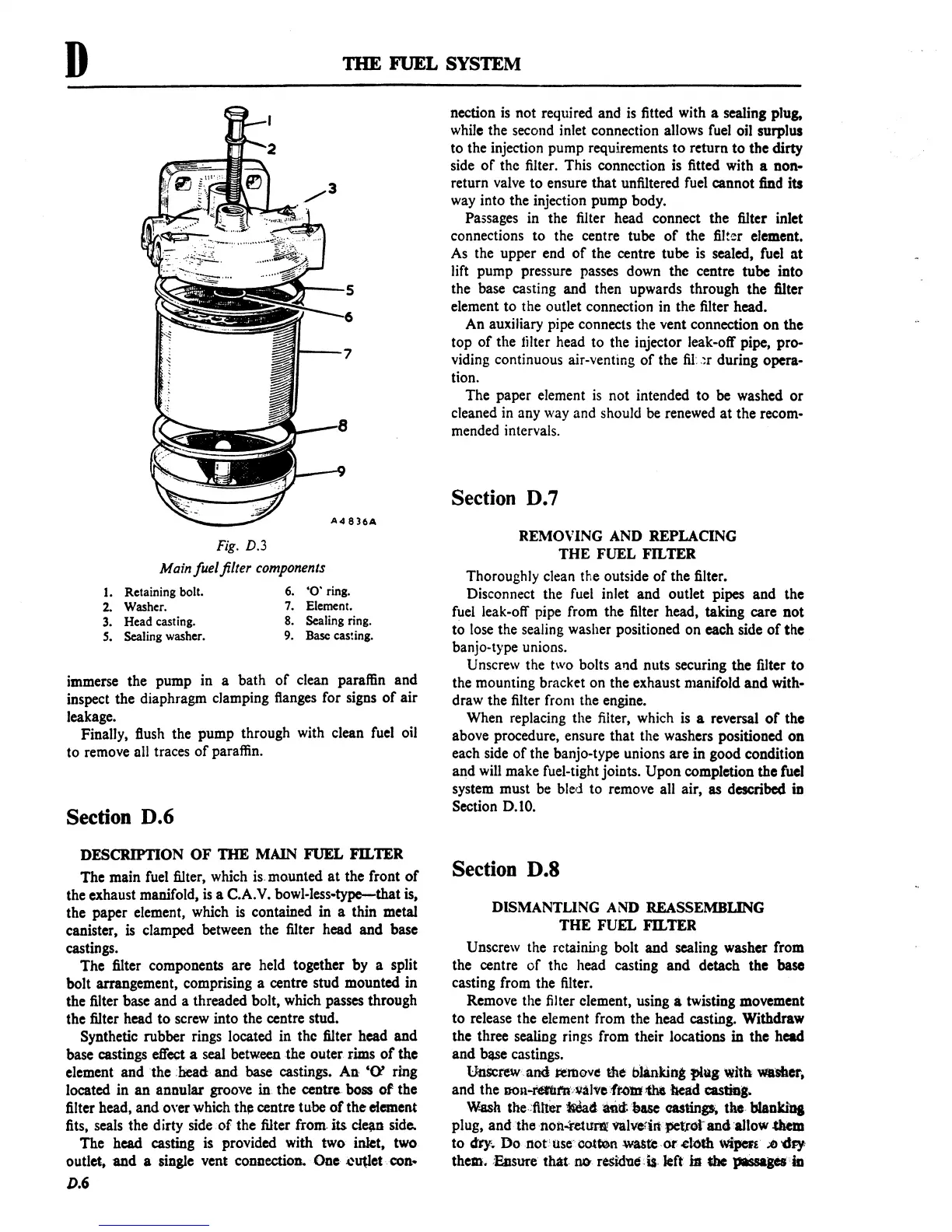

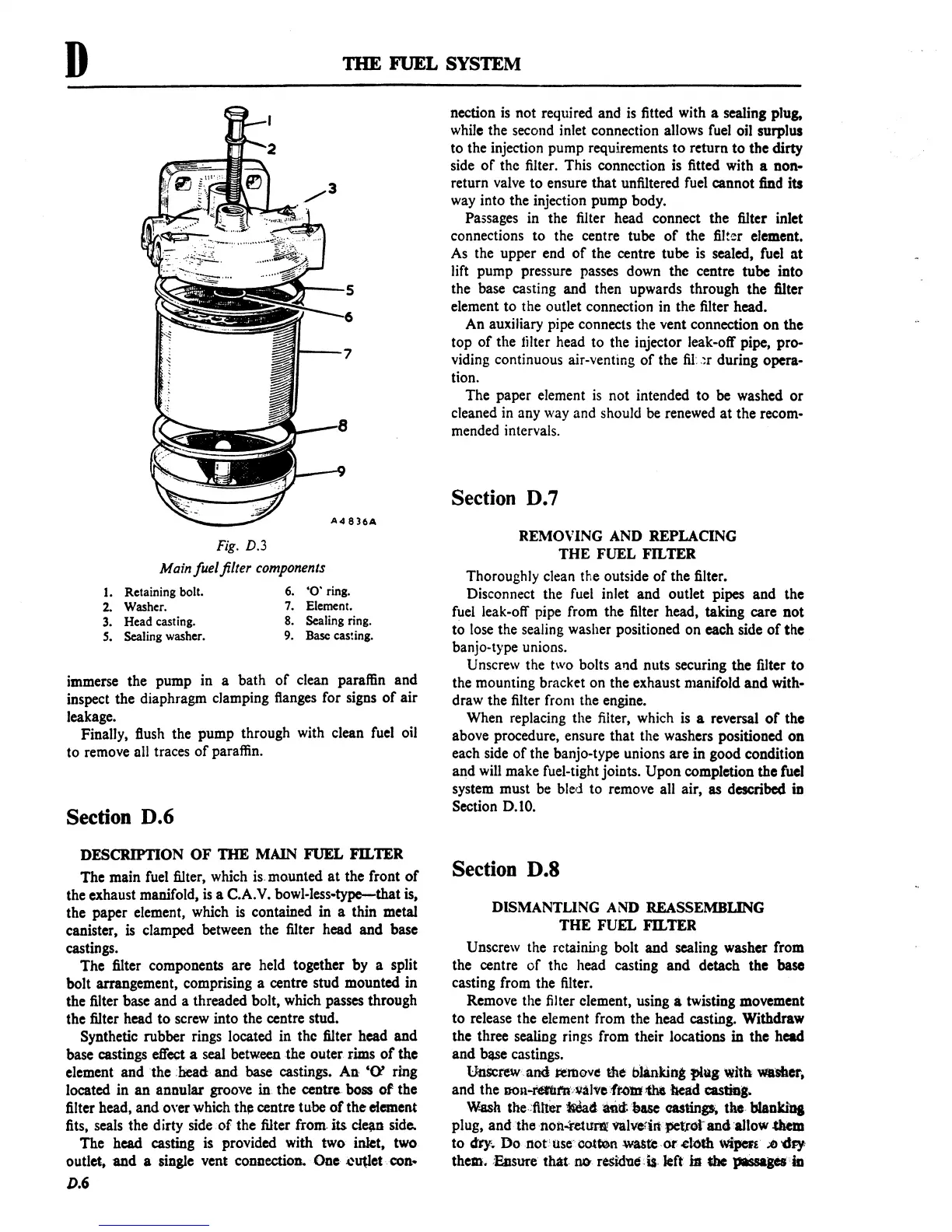

Fig. D.3

Main

fuel filter

components

1.

Retaining bolt.

6.

'0'

ring.

2.

Washer.

7.

Element.

3.

Head casting.

8.

Sealing

ring.

S.

Sealing washer.

9.

Base

caS!ing.

immerse the pump in a bath

of

clean paraffin

and

inspect the diaphragm clamping flanges for signs

of

air

leakage.

Finally, flush the

pump

through with clean fuel oil

to remove

all traces

of

paraffin.

Section D.6

DESCRIPTION

OF

TIlE

MAIN

FUEL

Fn.TER

The

main fuel filter, which

is-

mounted

at

the front

of

the exhaust manifold,

is

a C.A.V. bowl-less-type-that is,

the paper element, which

is

contained in a thin metal

canister, is clamped between the filter head

and

base

castings.

The filter components

are held together by a split

bolt arrangement, comprising a centre stud mounted in

the filter base and a threaded bolt, which passes through

the filter head

to

screw into the centre stud.

Synthetic rubber rings located in

the filter head

and

base

castings

effect

a

seal

between the outer rims

of

the

element

and

the :head

and

base castings. An'

'0'

ring

located in

an

annular groove in the

centre.

boss

of

the

filter head,

and

over which

thj::

centre tube

of

the

element

fits, seals the dirty side

of

the filter from. its

cle;\D

side.

The head

casting

is

provided with two inlet, two

outlet.

and

a single vent connection.

One

:c~et·.

con

..

D.6

nection

is

not required and

is

fitted with a sealing plug,

while the second inlet connection allows fuel oil surplus

to

the injection pump requirements

to

return

to

the dirty

side

of

the filter. This connection is fitted with a non-

return valve

to

ensure

that

unfiltered fuel cannot find its

way into the injection pump body.

Passages in the filter head connect the filter inlet

connections

to

the centre tube

of

the filter clement.

As the upper end

of

the centre tube

is

sealed, fuel

at

lift pump pressure passes down the centre tube into

the base casting and then upwards through the filter

element

to

the outlet connection in the filter head.

An auxiliary pipe connects the vent connection

on

the

top

of

the tilter head to the injector leak-off pipe, pro-

viding continuous air-venting

of

the

fiI:

_~r

during opera-

tion.

The paper element

is

not intended

to

be washed

or

cleaned in any way and should be renewed

at

the recom-

mended intervals.

Section D.7

REMOVING AND REPLACING

THE

FUEL FILTER

Thoroughly clean the outside

of

the filter.

Disconnect the fuel inlet

and

outlet pipes and the

fuel leak-off pipe from the filter head, taking care

not

to

lose the sealing washer positioned

on

each side

of

the

banjo-type unions.

Unscrew the two bolts alld nuts securing the filter

to

the mounting bracket

on

the exhaust manifold

and

with-

draw the filter from the engine.

When replacing the filter, which is

a reversal

of

the

above procedure, ensure that the washers positioned

on

each side

of

the banjo-type unions are in good condition

and will make fuel-tight joints.

Upon

completion

the

fuel

system must be bled to remove all air, as described

in

Section 0.10.

Section D.S

DISMANTLING AND REASSEMBLING

THE FUEL FILTER

Unscrew the retaining bolt

and

sealing washer from

the centre

of

the head casting

and

detach the base

casting from the filter.

Remove the filter clement, using

a twisting movement

to

release the element from the head casting. Withdraw

the three sealing rings from their locations

in the head

and

bltSe

castings.

Unscrew

and

&:tJ1l0VC!

Ute

blanking

flQg

with

_'Sher.

and the

DOn-nmtt'A,~al'\le:·fr'()IlfJftll

bead

castiD."

W.ash

Cbe.:1Ut~

~4

~d:.tN.se

castings;,

the-

blankias

plug,

andthenon..r~lIrl\!

ftlvefiR IlCtrot

and

:allow .cbm

to

dty.

Do

not'

user

oottoowa&k

-

or

.etotb wiperi'

;;e

'Cby

them. :Easure

that.llD

residuens· left

ia

the

passaPS'ia

Loading...

Loading...