THE FUEL SYSTEM

D

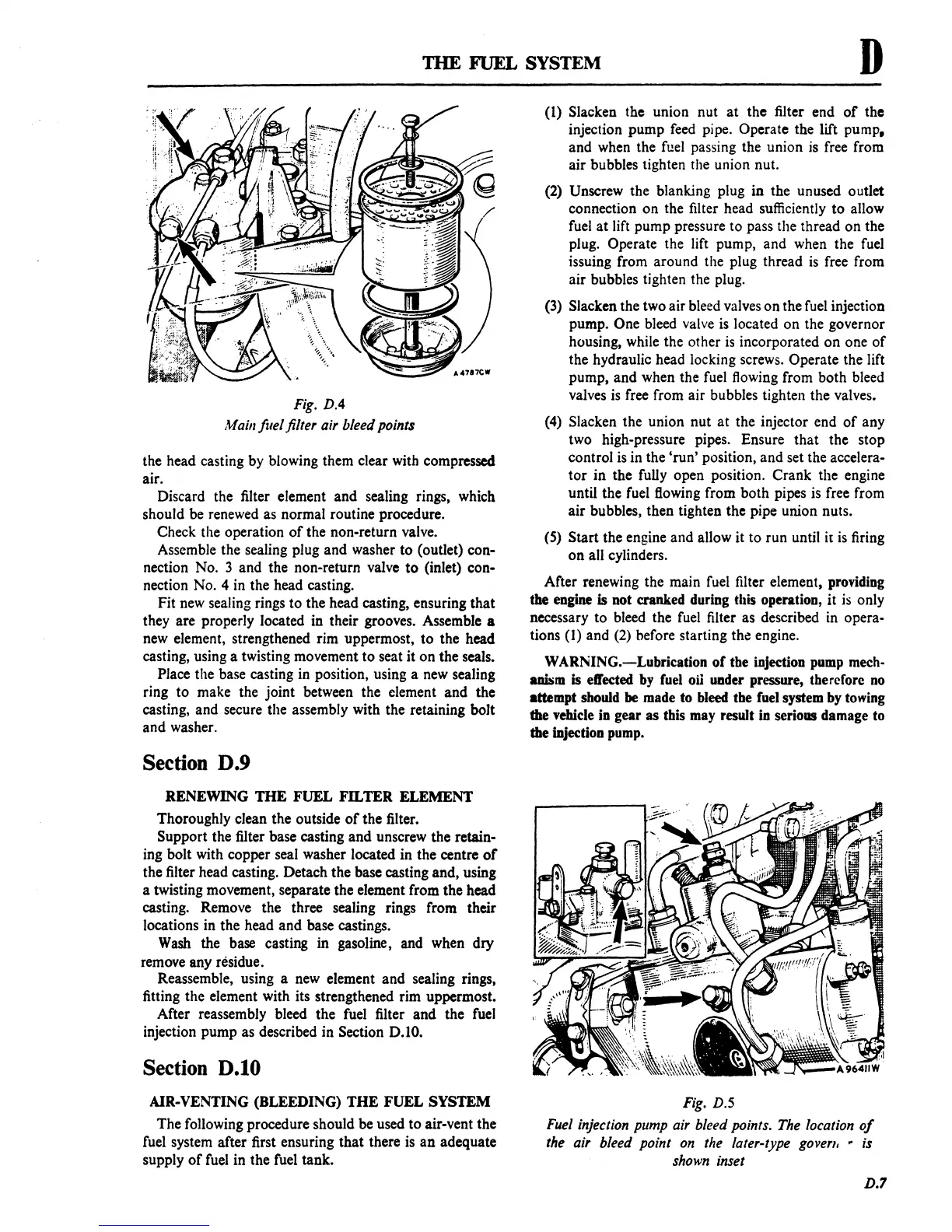

Fig. D.4

Main ftlel filter air bleed points

the head casting by blowing them clear with compressed

air.

Discard the filter element and sealing rings, which

should be renewed as normal routine procedure.

Check the operation

of

the non-return valve.

Assemble the sealing plug

and

washer

to

(outlet) con-

nection No. 3 and the non-return valve

to

(inlet) con-

nection No.

4 in the head casting.

Fit new sealing rings

to

the head casting, ensuring

that

they are properly located in their grooves. Assemble a

new element, strengthened rim uppermost,

to

the head

casting, using a twisting movement

to

seat it

on

the seals.

Place the base casting in position, using a new sealing

ring

to

make the joint between the element

and

the

casting, and secure the assembly with the retaining bolt

and

washer.

Section D.9

RENEWING

THE

FUEL

FaTER

ELEMENT

Thoroughly clean the outside

of

the filter.

Support the filter base casting

and

unscrew the retain-

ing bolt with copper seal washer located in the centre

of

the filter head casting. Detach the base casting and, using

a twisting movement, separate the element from the head

casting. Remove the three sealing rings from their

locations in the head

and

base castings.

Wash the base casting in gasoline, and when dry

remove any residue.

Reassemble, using a new element and sealing rings,

fitting the element with its strengthened rim uppermost.

After reassembly bleed the fuel filter

and

the fuel

injection pump as described in

Section

0.10.

Section 0.10

AIR-VENTING (BLEEDING)

THE

FUEL SYSTEM

The

following procedure should be used

to

air-vent the

fuel system after first ensuring that there is

an

adequate

supply

of

fuel in the fuel tank.

(1) Slacken the union nut

at

the filter end

of

the

injection pump feed pipe.

Operate the lift pump.

and when the fuel passing the union is free from

air bubbles tighten the union nut.

(2)

Unscrew the blanking plug in the unused outlet

connection

on

the filter head sufficiently

to

allow

fuel

at

lift pump pressure

to

pass the thread

on

the

plug.

Operate the lift pump, and when the fuel

issuing from around the plug thread

is

free from

air bubbles tighten the plug.

(3) Slacken the two air bleed valves

on

the fuel injection

pump.

One bleed valve is located

on

the governor

housing, while the other

is

incorporated

on

one

of

the hydraulic head locking screws. Operate the lift

pump,

and

when the fuel flowing from both bleed

valves

is

free from air bubbles tighten the valves.

(4) Slacken the union nut at the injector end

of

any

two high-pressure pipes. Ensure that the stop

control is in the

'run'

position, and set the accelera-

tor

in the fully open position. Crank the engine

until the fuel flowing from

both

pipes is free from

air

bubbles, then tighten the pipe union nuts.

(S) Start the engine and allow it to run until it

is

firing

on

all cylinders.

After renewing the main fuel filter element, providing

the

engine is not cranked during this operation,

it

is

only

necessary

to

bleed the fuel filter as described in opera-

tions

(1) and (2) before starting the engine.

WARNING.-Lubrication

of

tbe injection pump mech-

aDbim

is effected

by

fuel oil

UDder

pressure, tberefore

no

attempt should be made

to

bleed tbe fuel system by towing

the vehicle in gear as tbis may result in serious damage to

tbe iDjection pump.

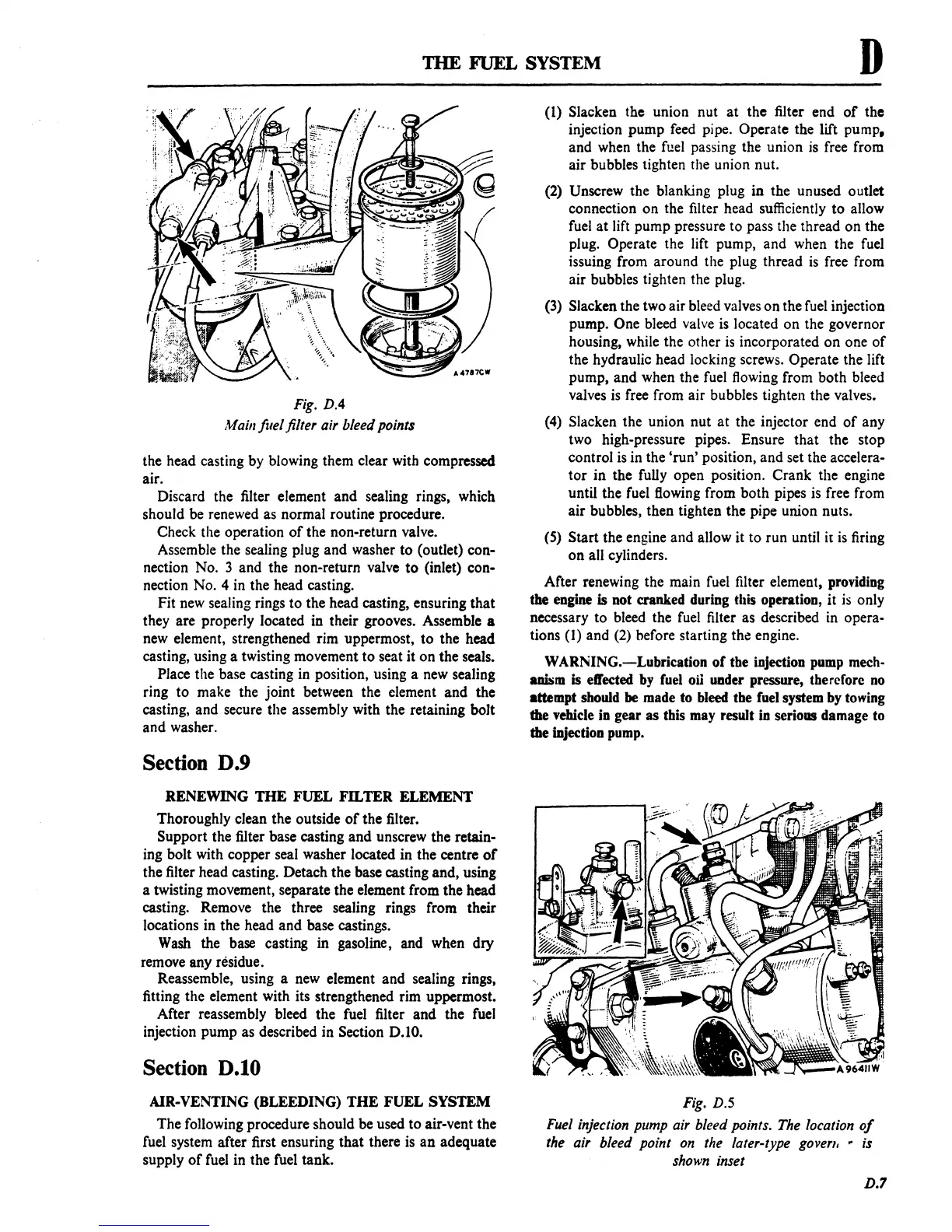

Fig.

D.S

Fuel injection pump air bleed points. The location

of

the air bleed point

on

the later-type goven. p is

shown inset

D.?

Loading...

Loading...