D

THE FUEL SYSTEM

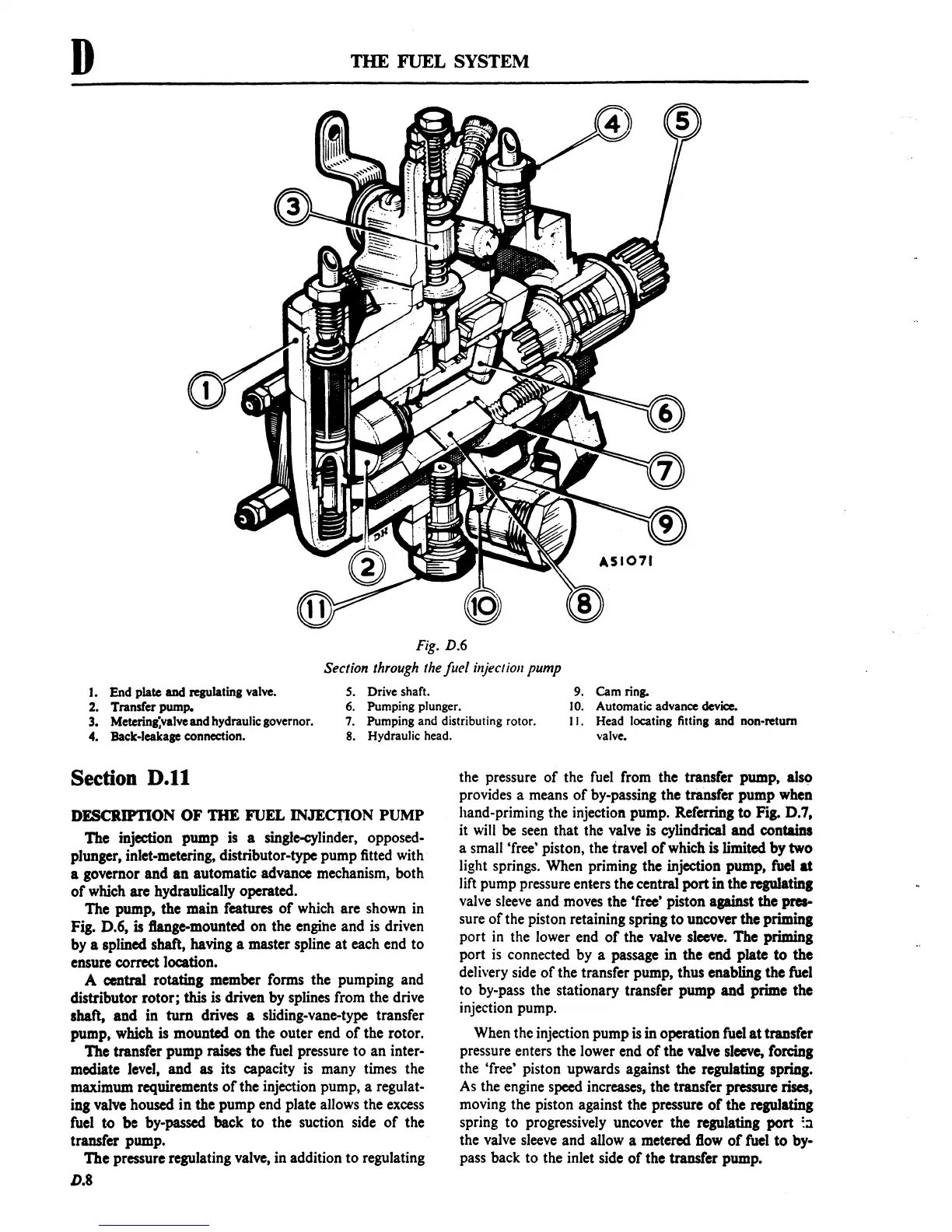

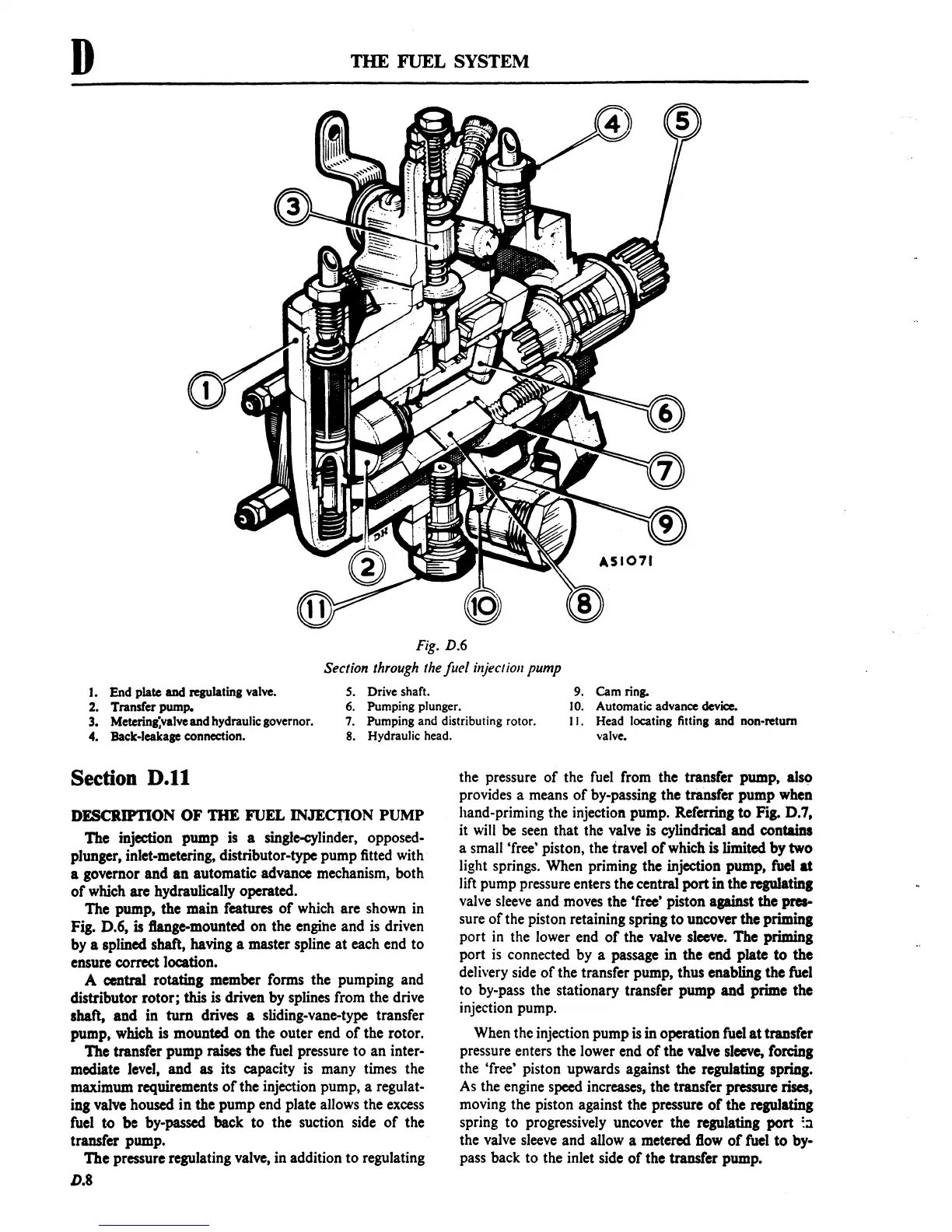

Fig. D.6

I. End plate

aDd

regulating valve.

Section through the juel injection pump

S.

Drive shaft.

9.

Cam ring.

2. Transfer pump.

6.

Pumping plunger.

10.

Automatic advance device.

3. Metcring;valve and hydraulic governor.

4. Back-leakage

connection.

7.

Pumping and distributing rotor.

S.

Hydraulic head.

I

I . Head locating fitting and non-return

valve.

Section

D.II

DFSCRIPrION OF THE FUEL INJECl10N PUMP

The

jnjection

pump

js

a single-cylinder, opposed-

plunger, inlet-metering, distributor-type pump fitted with

a governor and

an

automatic advance mechanism, both

of

which are hydraulically operated.

The pump, the main features

of

which are shown in

Fig. D.6,

is

ftange-mounted

on

the engihe and is driven

by a splined shaft, having a master spline

at

each end

to

ensure correct location.

A central rotating member forms the pumping and

distributor

rotor;

this is driven by splines from the drive

shaft,

and

in

turn

drives a sliding-vane-type transfer

pump, which is mounted

on

the outer end

of

the rotor.

The transfer pump raises the fuel pressure

to

an

inter-

mediate level, and as its capacity is many times the

maximum requirements

of

the injection pump, a regulat-

ing

valve housed

in

the pump end plate allows the excess

fuel

to

be by-passed back

to

the suction side

of

the

transfer pump.

The

pressure regulating valve, in addition

to

regulating

D.S

the pressure

of

the fuel from the transfer pump, also

provides a means

of

by-passing the transfer

pump

when

hand-priming the injection pump.

Referring

to

Fig. D.7,

it will

be

seen that the valve is cylindrical

and

contains

a small 'free' piston, the travel

of

which is limited

by

two

light springs. When priming the injection pump, fuel

at

lift pump pressure enters the central

port

in the regulating

valve sleeve and moves the 'free' piston against the pres-

sure

of

the piston retaining spring

to

uncover the priming

port

in

the lower end

of

the valve sleeve. The priming

port

is

connected by a passage in the end plate

to

the

delivery side

of

the transfer pump, thus enabling

the

fuel

to by-pass the stationary transfer pump

and

prime the

injection pump.

When the injection pump

is

in operation fuel

at

transfer

pressure enters the lower end

of

the valve sleeve, forcing

the 'free' piston upwards against the regulating spring.

As the engine speed increases, the transfer pressure rises,

moving the piston against the pressure

of

the regulating

spring

to

progressively uncover the regulating

port

::1

the valve sleeve and allow a metered flow

of

fuel

to

by-

pass back to the inlet side

of

the transfer pump.

Loading...

Loading...