THE FUEL SYSTEM

D

B

Fig.

D.7

Sectioll

throllg17

tfle

end-plate alld reguhllillg \'ah'e

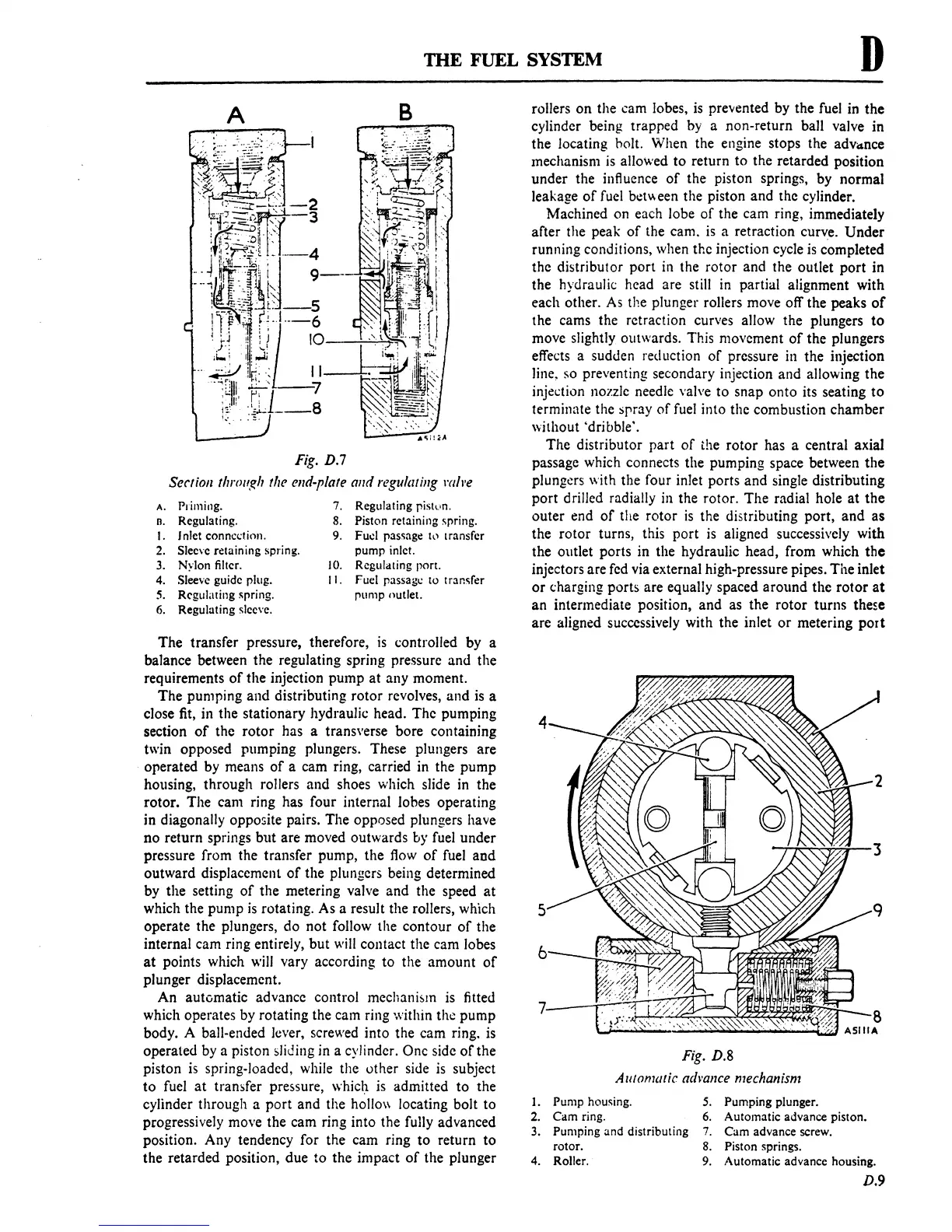

A. Priming.

7.

Regulating riSk,n.

n.

Regulating.

8.

Piston retaining spring.

I.

J nlet

conned

inn. 9.

Fud

passage

hl

transfer

2.

Sleeve retaining spring.

pump

inlet.

3.

Nylon filter.

10.

Regulating port.

4. Sleeve guide

plug.

11.

Fuel passag\: to transfer

5.

Regulating spring.

pump

nutlet.

6. Regulating slee\'e.

The transfer pressure, therefore,

is

controlled by a

balance between the regulating spring pressure and the

requirements

of

the injection pump

at

any moment.

The pumping and distributing rotor revolves, and

is

a

close fit, in the stationary

hydraulic head. Thc pumping

section

of

the

rotor

has a transverse bore containing

twin opposed pumping plungers. These plungers are

operated by means

of

a cam ring, carried in the pump

housing, through rollers and shoes which slide

in

the

rotor. The cam ring has four internal lobes operating

in diagonally opposite pairs. The opposed plungers have

no

return springs but are moved outwards

by

fuel under

pressure from the transfer pump, the

flow

of

fuel and

outward displacement

of

the plungers being determined

by the setting

of

the metering valve and the speed

at

which the pump

is

rotating. As a result the rollers, which

operate the plungers, do not follow the contour

of

the

internal cam ring entirely,

but

will

contact the cam lobes

at

points which

will

vary according to the amount

of

plunger displacement.

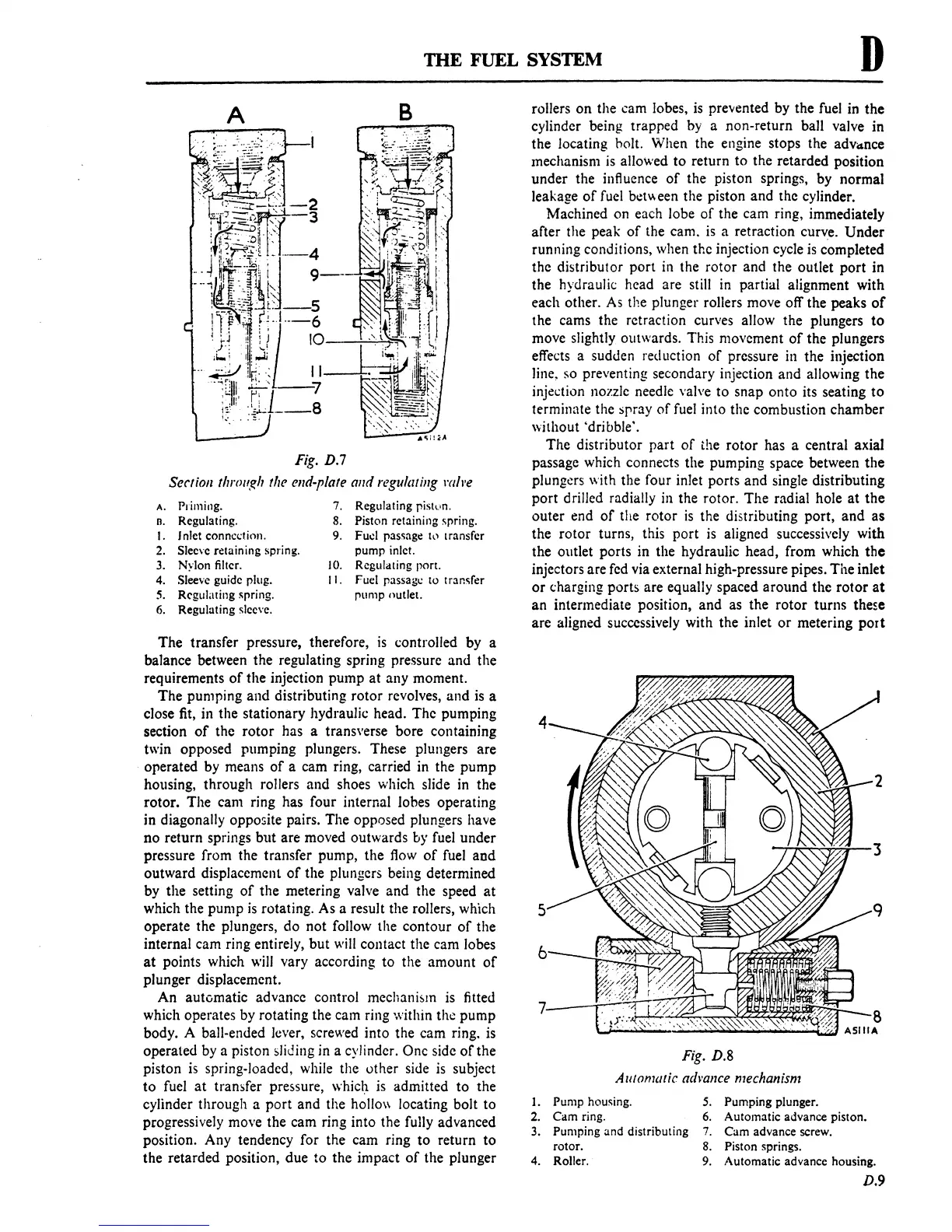

An

automatic advance control

mechani5lTI

is

fitted

which operates by rotating the cam ring within the pump

body. A ball-ended lever, screwed into the cam ring.

is

operated by a piston sliding in a cylinder. One side

of

the

piston

is

spring-loaded, while the other side

is

subject

to

fuel

at

transfer pressure, which

is

admitted to the

cylinder through a

port

and the hollo\\ locating bolt to

progressively move the cam ring into the fully advanced

position. Any tendency for the cam ring to return to

the retarded position, due to the impact

of

the plunger

rollers

on

the cam lobes,

is

prevented by the fuel in the

cylinder being trapped by a non-return ball valve in

the locating holt. When the engine stops the

adv"nce

mechanism

is

allowed to return to the retarded position

under the influence

of

the piston springs, by normal

leakage

of

fuel bct\l,een the piston and the cylinder.

Machined on each lobe

of

the cam ring, immediately

after the peak

of

the cam.

is

a retraction curve.

Under

running conditions, when thc injection cycle

is

completed

the distributor

port

in

the rotor and the outlet

port

in

the hydraulic head are still in partial alignment with

each other. As the plunger rollers move off the peaks

of

the cams the retraction curves allow the plungers

to

move slightly outwards. This movement

of

the plungers

effects a sudden reduction

of

pressure in the injection

line,

so preventing secondary injection and allowing the

injedion nozzle needle valve to snap onto its seating

to

terminate the spray

of

fuel into the combustion chamber

without 'dribble'.

The distributor part

of

the rotor has a central axial

passage which connects the pumping space between

the

plungers with the four inlet ports and single distributing

port drilled radially in the rotor. The radial hole at the

outer end

of

the rotor

is

the distributing port,

and

as

the rotor turns, this port

is

aligned successively with

the outlet ports in the hydraulic head, from which

the

injectors are fed via external high-pressure pipes. The inlet

or

charging ports are equally spaced around the

rotor

at

an intermediate position, and as the rotor turns these

are aligned successively with the inlet

or

metering

port

4

5

6

Fig.

D.8

Alllomaric

Q(h'ance

mechanism

1. Pump housing.

2.

Cam

ring.

3.

Pumping

and

distributing

rotor.

4. Roller.

5.

Pumping plunger.

6.

Automatic advance piston.

7.

Cam

advance screw.

8.

Piston springs.

9.

Automatic advance housing.

D.9

Loading...

Loading...