D

THE FUEL SYSTEM

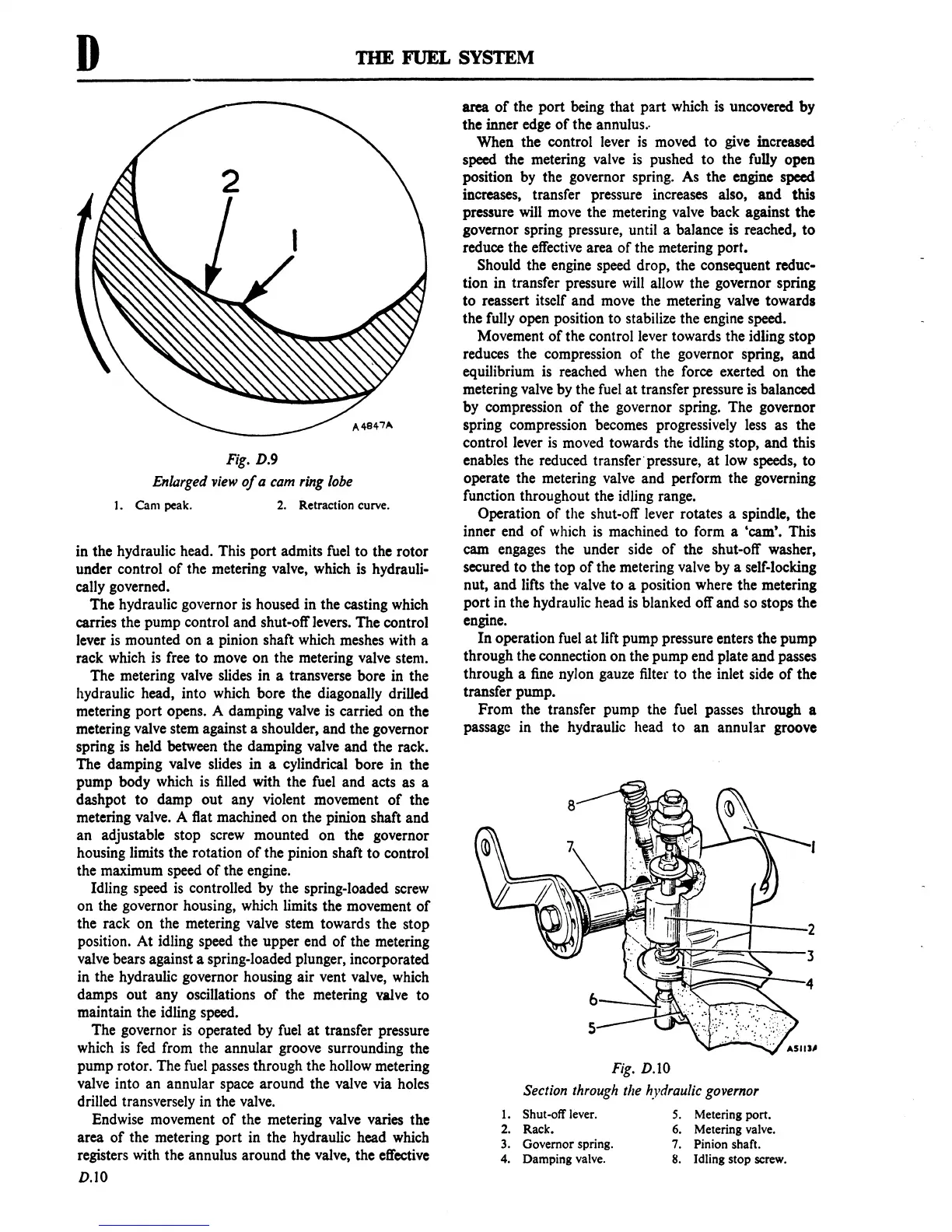

Fig.

D.9

Enlarged

'View

of

a cam

ring

lobe

I.

Cam

peak.

2.

Retraction curve.

in the hydraulic head. This

port

admits fuel

to

the

rotor

under control

of

the metering valve, which is hydrauli-

cally governed.

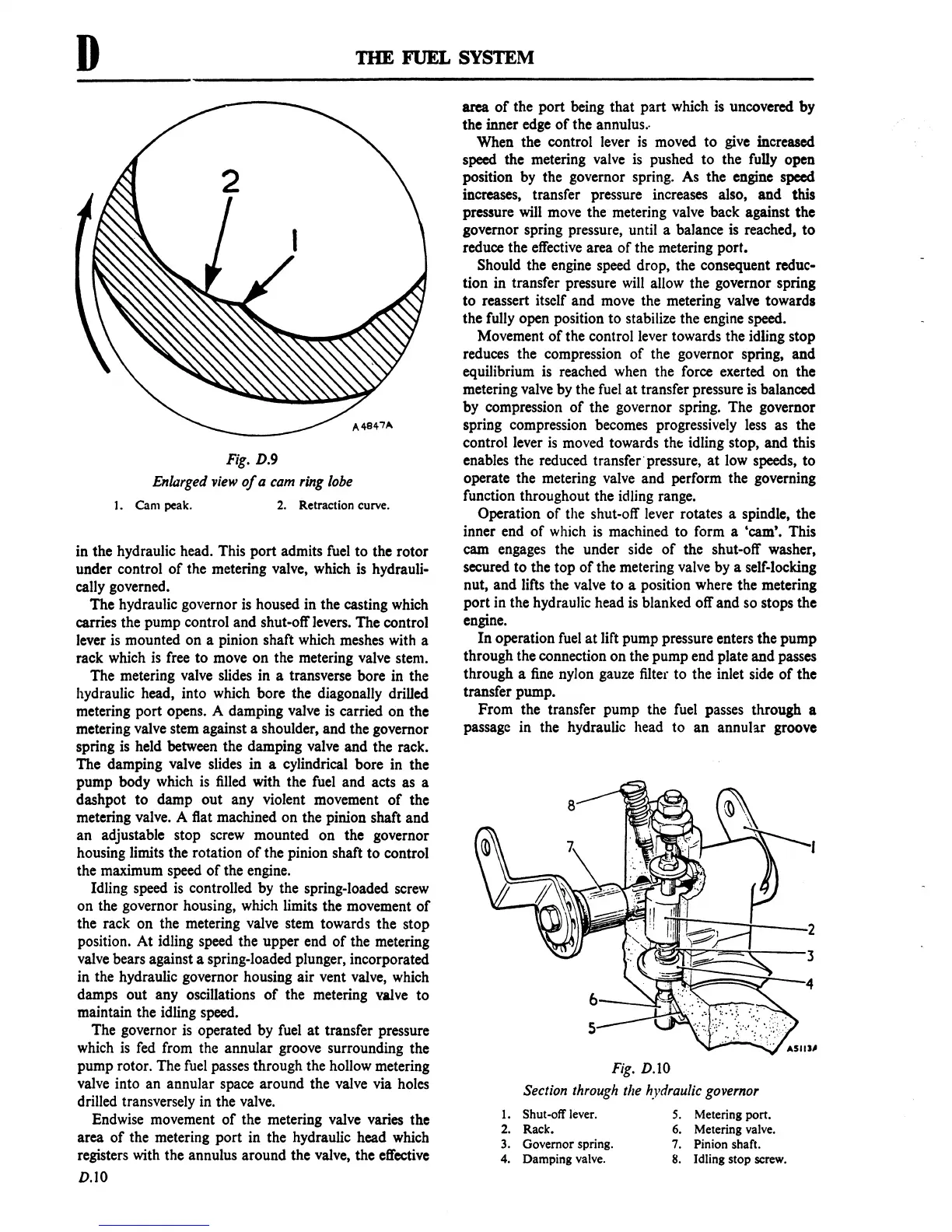

The

hydraulic governor

is

housed in the casting which

carries the pump control

and

shut-off levers.

The

control

lever is mounted

on

a pinion shaft which meshes with a

rack which is free

to

move

on

the metering valve stem.

The metering valve slides in a transverse bore in the

hydraulic head, into which bore the diagonally driUed

metering

port

opens. A damping valve is carried

on

the

metering valve stem against a shoulder, and the governor

spring

is

held between the damping valve

and

the rack.

The damping valve slides

in

a cylindrical

bore

in the

pump body which is filled with the fuel

and

acts as a

dashpot

to

damp

out

any violent movement

of

the

metering valve. A flat machined

on

the pinion shaft

and

an

adjustable stop screw mounted

on

the governor

housing limits the rotation

of

the pinion shaft

to

control

the maximum speed

of

the engine.

Idling speed

is

controlled by the spring-loaded screw

on

the governor housing, which limits the movement

of

the rack

on

the metering valve stem towards the stop

position.

At

idling speed the upper end

of

the metering

valve bears against a spring-loaded plunger, incorporated

in the hydraulic governor housing

air

vent valve, which

damps

out

any oscillations

of

the metering valve

to

maintain the idling speed.

The governor is operated by fuel

at

transfer pressure

which

is

fed from the annular groove surrounding the

pump rotor. The fuel passes through the hollow metering

valve into an annular space around the valve via holes

drilled transversely in the valve.

Endwise movement

of

the metering valve varies the

area

of

the metering

port

in the hydraulic head which

registers with the annulus around the valve, the effective

D.IO

area

of

the

port

being that

part

which is uncovered

by

the inner edge

of

the annulus.·

When the control lever is moved

to

give increased

speed the metering valve is pushed

to

the fully open

position by the governor spring. As the engine speed

increases, transfer pressure increases also,

and

this

pressure will move the metering valve back against

the

governor spring pressure, until a balance is reached,

to

reduce the effective area

of

the metering port.

Should the engine speed drop, the consequent reduc-

tion in transfer pressure will allow the governor spring

to

reassert itself and move the metering valve towards

the fully open position

to

stabilize the engine speed.

Movement

of

the control lever towards the idling stop

reduces the compression

of

the governor spring,

and

equilibrium is reached when the force exerted

on

the

metering valve by the fuel

at

transfer pressure is balanced

by compression

of

the governor spring.

The

governor

spring compression becomes progressively less as the

control lever

is

moved towards

tht

idling stop,

and

this

enables the reduced transfer"pressure,

at

low speeds,

to

operate the metering valve and perform the governing

function throughout the idling range.

Operation

of

the shut-off lever rotates a spindle, the

inner end

of

which is machined

to

form a 'cam'. This

cam engages the under side

of

the shut-off washer,

secured to the

top

of

the metering valve by a self-locking

nut,

and

lifts the valve

to

a position where the metering

port

in the hydraulic head is blanked off

and

so stops the

engine.

In

operation fuel

at

lift pump pressure enters the

pump

through the connection

on

the pump end plate

and

passes

through a fine nylon gauze filter

to

the inlet side

of

the

transfer pump.

From

the transfer pump the fuel passes through a

passage in the hydraulic head

to

an

annular groove

Fig.

D.1O

Section

through

the

hydraulic

go

'Vernor

1. Shut-off

lever.

S.

Metering port.

2.

Rack.

6.

Metering

valve.

3.

Governor spring.

7.

Pinion shaft.

4. Damping

valve.

8.

Idling stop

screw.

Loading...

Loading...