TIlE FUEL SYSTEM

D

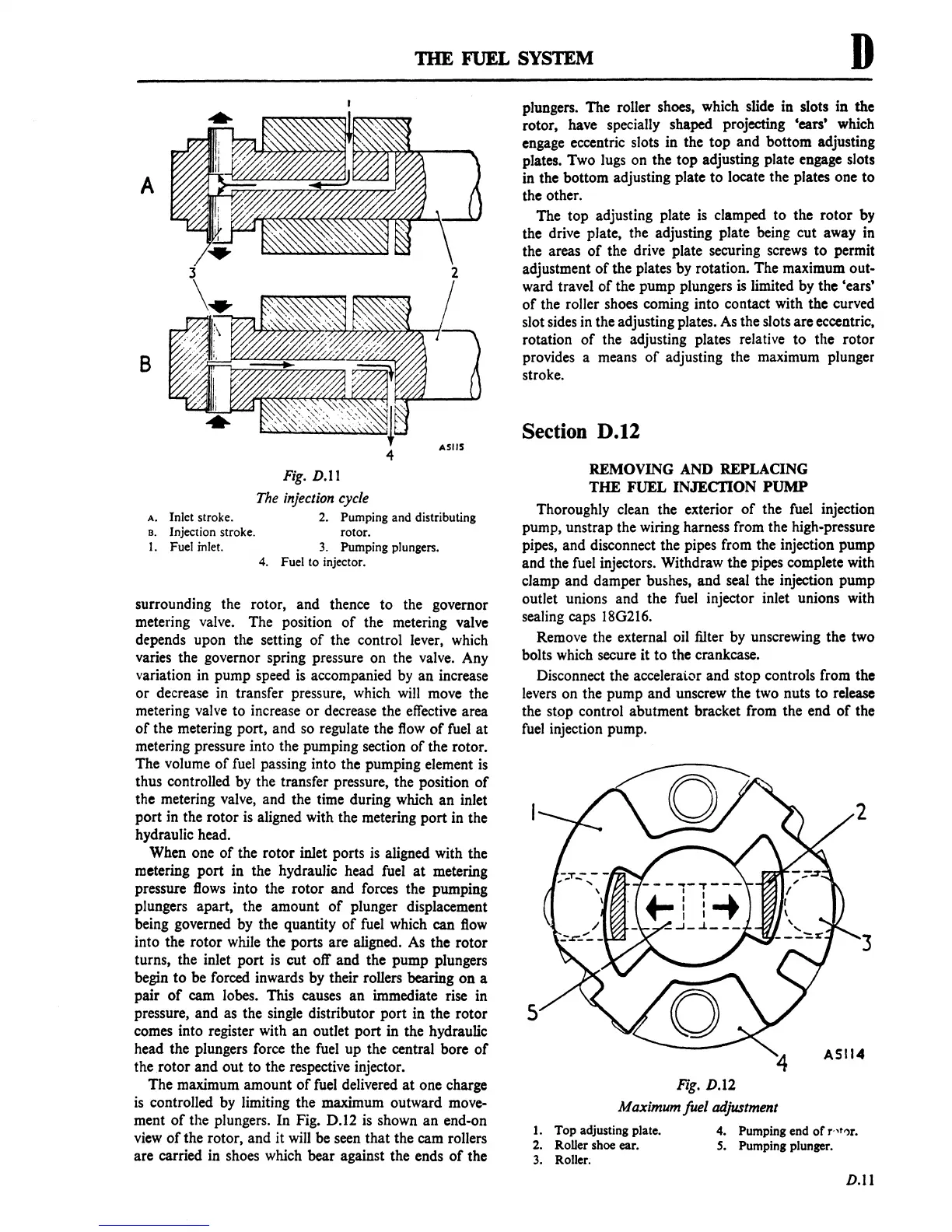

A

B

A.

Inlet stroke.

B. Injection stroke.

1.

Fuel inlet.

Fig.

D.ll

The

injection

cycle

2.

Pumping and distributing

rotor.

3.

Pumping plungers.

4.

Fuel to injector.

surrounding the rotor, and thence to the governor

metering valve. The position

of

the metering valve

depends upon the setting

of

the control lever, which

varies the governor spring pressure on the valve. Any

variation in pump speed

is

accompanied

by

an increase

or decrease

in

transfer pressure, which

will

move the

metering valve to increase or decrease the

effective

area

of

the metering port, and

so

regulate the

flow

of

fuel

at

metering pressure into the pumping section

of

the rotor.

The volume

of

fuel

passing into the pumping element

is

thus controlled by the transfer pressure, the position

of

the metering valve, and the time during which an inlet

port

in

the rotor

is

aligned with the metering port in the

hydraulic head.

When one

of

the rotor inlet ports

is

aligned with the

metering port in the hydraulic head fuel

at

metering

pressure

flows

into the rotor and forces the pumping

plungers apart, the amount

of

plunger displacement

being governed by the quantity

of

fuel

which can

flow

into the rotor while the ports are aligned.

As

the rotor

turns, the inlet port

is

cut off and the pump plungers

begin to be forced inwards by their rollers bearing

on

a

pair

of

cam lobes. This causes an immediate rise in

pressure, and as the single distributor port in the rotor

comes into register with an outlet port in the hydraulic

head the plungers force the

fuel

up the central bore

of

the .rotor and out to the respective injector.

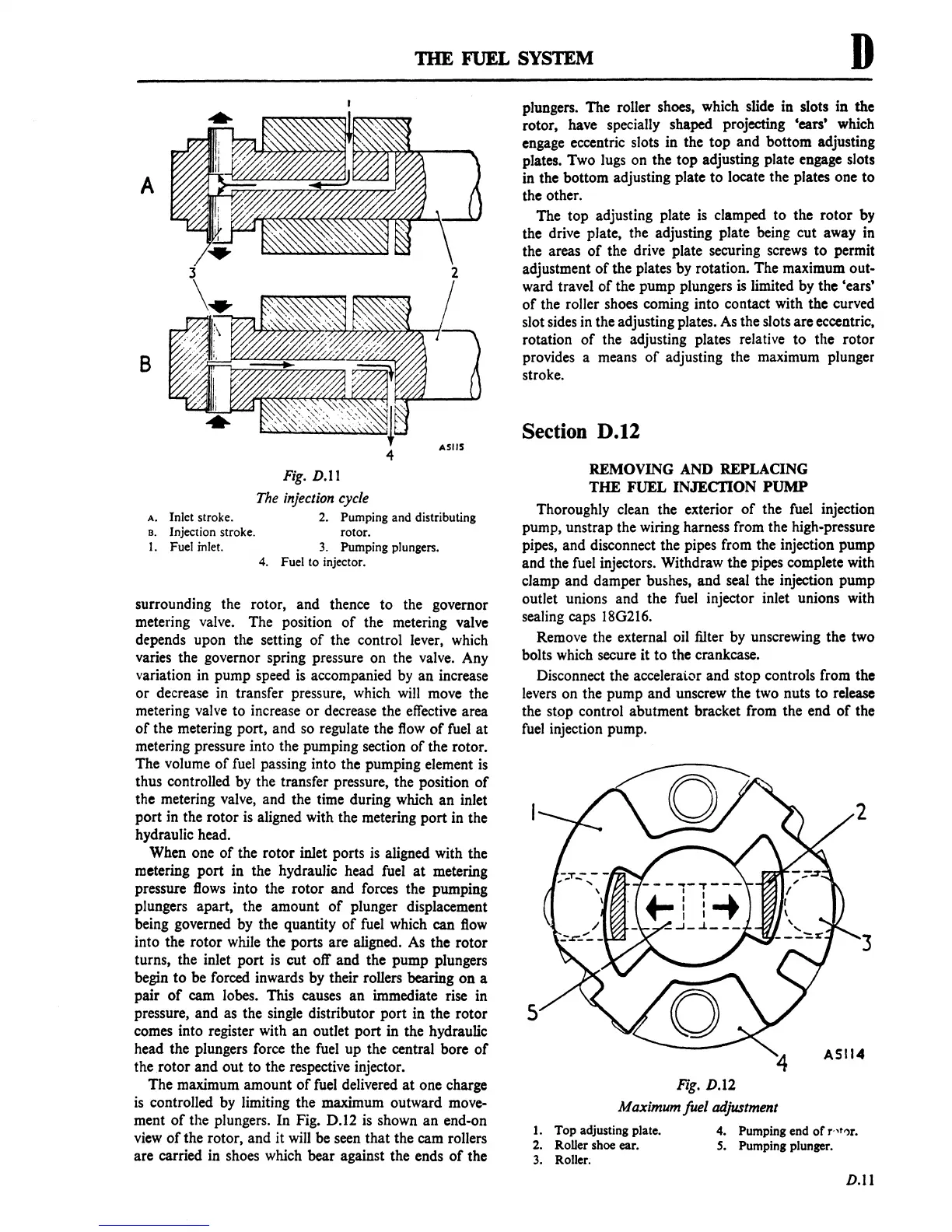

The maximum amount

of

fuel

delivered

at

one charge

is

controlled by limiting the maximum outward move-

ment

of

the plungers. In Fig. D.12

is

shown an end-on

view

of

the rotor, and it

will

be seen that the cam rollers

are carried in shoes which bear against the ends

of

the

plungers. The roller shoes, which slide in slots in the

rotor, have specially shaped projecting 'ears' which

engage eccentric slots in the top and bottom adjusting

plates. Two lugs on the top adjusting plate engage slots

in the bottom adjusting plate to locate the plates one to

the other.

The top adjusting plate

is

clamped to the rotor by

the drive plate, the adjusting plate being cut away in

the areas

of

the drive plate securing screws to permit

adjustment

of

the plates by rotation. The maximum out-

ward travel

of

the pump plungers

is

limited by the 'ears'

of

the roller shoes coming into contact with the curved

slot sides

in

the adjusting plates.

As

the slots are eccentric,

rotation

of

the adjusting plates relative to the rotor

provides a means

of

adjusting the maximum plunger

stroke.

Section D.12

REMOVING

AND

REPLACING

THE FUEL

INJECDON

PUMP

Thoroughly clean the exterior

of

the

fuel

injection

pump, unstrap the wiring harness from the high-pressure

pipes, and disconnect the pipes from the injection pump

and the

fuel

injectors. Withdraw the pipes complete with

clamp and damper bushes, and seal the injection pump

outlet unions and the

fuel

injector inlet unions with

sealing caps

18G216.

Remove the external oil filter by unscrewing the two

bolts which secure it to the crankcase.

Disconnect the accelerai.or and stop controls from the

levers

on the pump and unscrew the two nuts to release

the stop control abutment bracket from the end

of

the

fuel

injection pump.

5

Fig.

D.l2

Maximum fuel adjustment

1. Top adjusting plate.

4.

Pumping end

of

r·,t')r.

2.

RoUer

shoe ear.

S.

Pumping plunger.

3.

Roller;

D.ll

Loading...

Loading...