D

THE FUEL SYSTEM

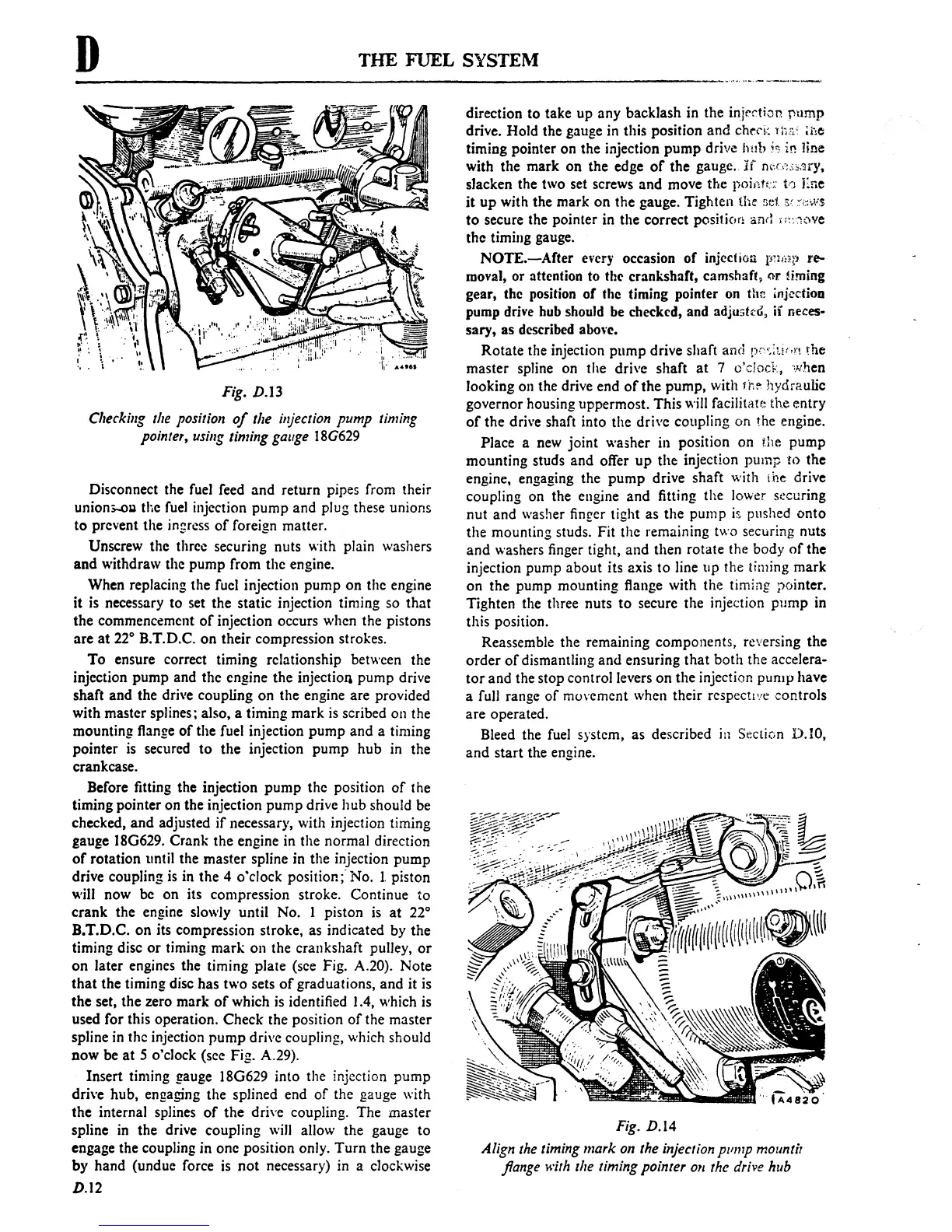

Fig. D.13

Checkillg the position

of

the injection pump timing

pointer,

usillg timing gauge

18G629

Disconnect

the

fuel feed

and

return

pipes from their

union:;..og the fuel injection

pump

and

plug these unions

to

prevent

the

ingress

of

foreign matter.

Unscrew

the

three securing nuts with plain washers

and

withdraw

the

pump

from

the

engine.

When

replacing

the

fuel injection

pump

on

the

engine

it

is necessary

to

set

the

static

injection timing so

that

the

commencement

of

injection occurs when

the

pistons

are

at

22° B.T.D.C.

on

their

compression strokes.

To

ensure correct timing relationship between

the

injection

pump

and

the

engine

the

injection

pump

drive

shaft

and

the

drive coupling

on

the

engine

are

provided

with

master splines; also, a timing

mark

is scribed on

the

mounting

flange

of

the

fuel injection

pump

and

a timing

pointer

is secured

to

the

injection

pump

hub

in

the

crankcase.

Before fitting

the

injection

pump

the

position

of

the

timing

pointer

on

the

injection

pump

drive

hub

should be

checked,

and

adjusted

if

necessary, with injection timing

gauge 18G629.

Crank

the

engine in

the

normal

direction

of

rotation

until

the

master

spline in

the

injection

pump

drive coupling is in

the

4

o'clock

position;-

No.

1.

piston

will

now

be

on

its compression stroke.

Continue

to

crank

the

engine slowly

until

No.

1

piston

is

at

2r

B.T.D.C.

on

its compression stroke, as indicated

by

the

timing disc

or

timing

mark

on

the

crankshaft

pulley,

or

on

later

engines

the

timing

plate

(see Fig. A.20).

Note

that

the

timing disc

has

two

sets

of

graduations,

and

it

is

the

set,

the

zero

mark

of

which is identified 1.4, which is

used

for

this operation.

Check

the position

of

the

master

spline in

the

injection

pump

drive coupling, which

should

DOW

be

at

5 o'clock (see Fig. A.29).

Insert

timing gauge 18G629

into

the injection

pump

drive

hub,

engaging

the

splined

end

of

the

gauge with

the

internal splines

of

the

drive coupling.

The

master

spline in

the

drive

coupling

will allow

the

gauge

to

engage the coupling

in

one

position

only.

Turn

the

gauge

by

hand

(undue force is

not

necessary) in a clockwise

D.l2

direction

to

take

up

any

backlash

in

the

injection

pump

drive.

Hold

the

gauge in this position

and

chrn:

n,';: ti,e

timing

pointer

on

the

injection

pump

drive

h!lb

is

in

line

with

the

mark

on

the

edge

of

the

gauge.

if

n\:U;,i,;~ry.

slacken the two set screws

and

move

the

poiM:::'

t')

Ene

it

up

with

the

mark

on

the

gauge.

Tighten

I.he

:;eI

SI

~',~W,S

to

secure the

pointer

in

the

correct

position and i

,,:,~(we

the

timing gauge.

NOTE.-After

every occasion

of

injcclioll

l"M,P

re-

moval, or attention to the crankshaft, camshaft,

or

liming

gear, the position

of

the timing pointer on

th(;

injection

pump drive bub should be checked, and adjusttG, if nel:es-

sary,

as described abol·e.

Rotate

the injection

pump

drive shaft

and

pr'<;;t!(,n

the

master

spline on

the

drive

shaft

at

7 o'clock, 'when

looking

on

the

drive

end

of

the

pump,

with

jh~

hydraulic

governor

housing

uppermost.

This

will facilitau: the

entry

of

the

drive shaft

into

the

drive

coupling

on

the engine.

Place

a new

joint

washer

in

position

on

the

pump

mounting

studs

and

offer

up

the

injection

pump

to

the

engine, engaging

the

pump

drive

shaft

with the drive

coupling on

the

engine

and

fitting

the

lower securing

nut

and

washer finger tight as

the

pump

i$

pushed

onto

the

mounting

studs. Fit

the

remaining two securing nuts

and

washers finger tight,

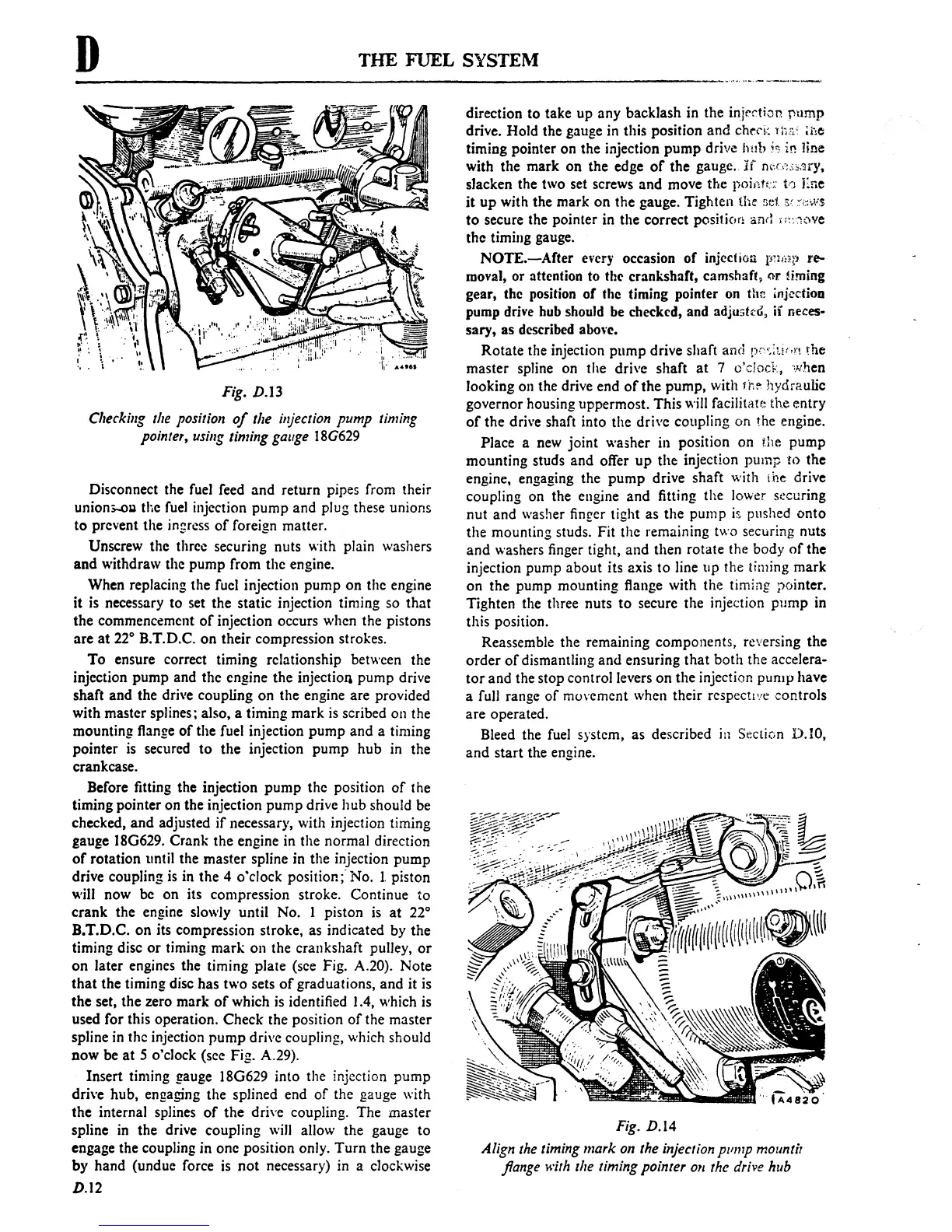

and

then

rotate

the

body

of

the

injection

pump

about

its

axis

to

line tip

the

timing

mark

on

the

pump

mounting

flange with

the

timing

}">ointer.

Tighten

the three

nuts

to

secure

the

injection

pump

in

this position.

Reassemble

the

remaining

components,

reversing

the

order

of

dismantling

and

ensuring

that

both

the

accelera-

tor

and

the

stop

control

levers

on

the

injection

pump

have

a full range

of

muvement when

their

rcspectt'!c

controls

are

operated.

Bleed the fuel system, as described

ill

SecLiGn

D.

IO,

and

start

the engine.

Fig. D.14

Align the timing mark on the injection pllmp

mOllntil

flange with the timing pointer

011

the drive hllb

Loading...

Loading...