WIKA operating instructions RTD and TC, intrinsically safe designs

3345267.08 06/2011 GB/D

29

GB

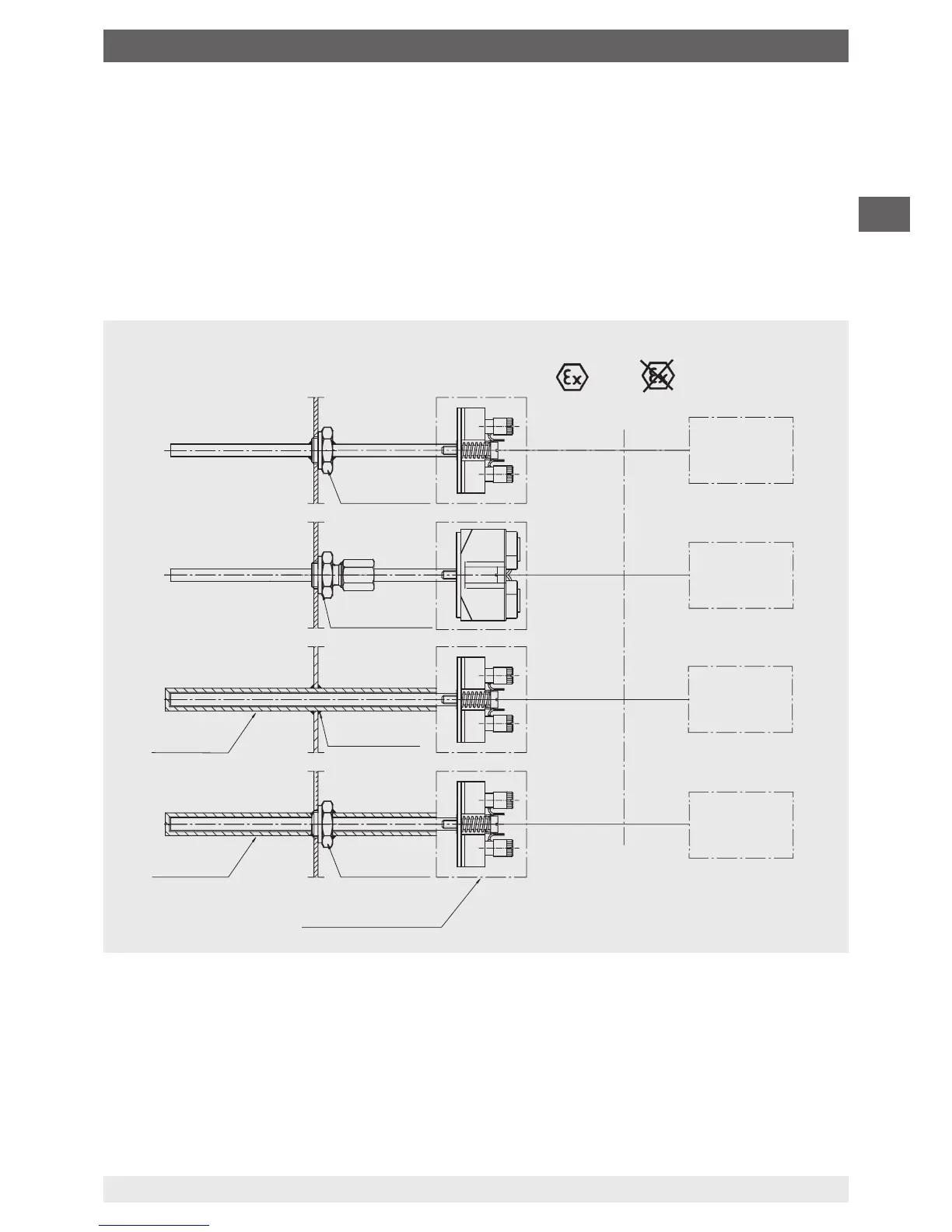

Zones 1, 2 or

Zones 21, 22

Hazardous area

Safe area

Thermowell

Thermowell

welded

TWxx

TWxx

Process

connection

Connection head/

Field housing

Tx10-B

Tx10-C

Tx10-C

Tx10-D

Tx10-H

Tx10-H

Option:

with built-in

transmitter:

e.g. T32

Tx10-A

Process

connection

Compression

tting

Associated

electrical equipment

Intrinsically

safe supply or

suitable barrier

e.g. transmitter power supply

KFD2-STC4-Ex1

WIKA Art. No.: 2341268

e.g. Zener barrier Z954

for Pf100-3L

WIKA Art. No.: 3247938

Intrinsically

safe supply or

suitable barrier

Intrinsically

safe supply or

suitable barrier

Intrinsically

safe supply or

suitable barrier

Tx10-A

Tx10-A

Tx10-A

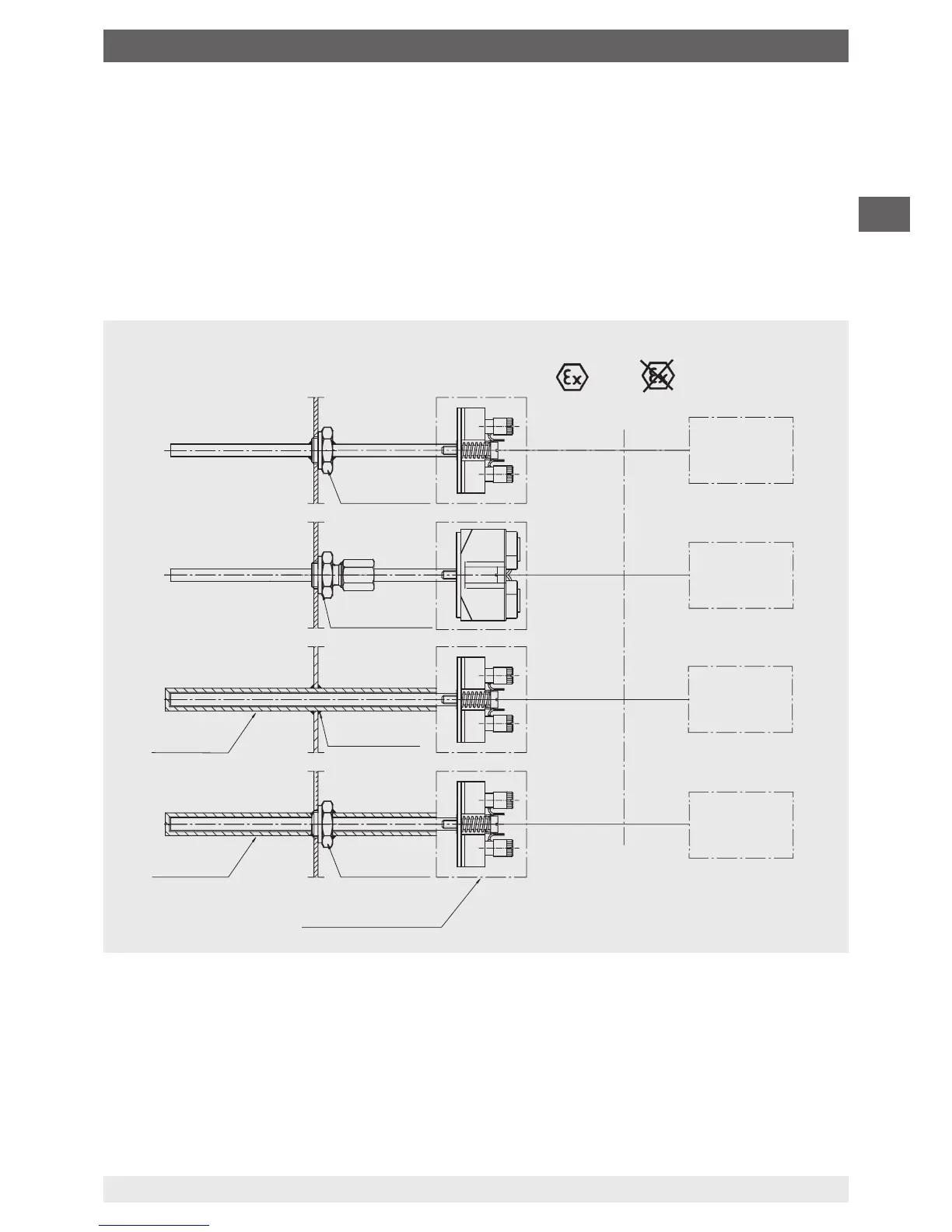

Zones 0, 1, 2 or

Zones 20, 21, 22

The sensor together with housing or connection head is located in Zone 0 (Zone 20). An Ex

ia type circuit must be used. A zone separation is deemed to exist if the process connection

guarantees a suciently tight gap (IP 67) between the less hazardous zone and the Zone 0.

Examples of suitable process connections include gas-tight standardised industrial anges,

threaded connections or pipe connections.

7.4.2 Possible installation methods with the marking II 1/2 Ex ib IIC T6 Ga/Gb or

II 1/2 D Ex ib IIIC T65 °C Da/Db

The sensor or thermowell tip protrudes into Zone 0. The housing or connection head is in Zone 1

(Zone 21) or Zone 2 (Zone 22). It is sucient to use an Ex ib type circuit.

Zone separation is guaranteed if suciently-tight (IP 67) process connections are used.

Examples of suitable process connections include gas-tight standardised industrial anges,

threaded connections or pipe connections.

7. Information on mounting, operation in hazardous areas (Europe)

Loading...

Loading...