WARNING: rotate the wheel without pushing too much the blade

against it.

The instrument is normally delivered adjusted on the minmum

value of its range (factory calibration).

Calibration of dead band

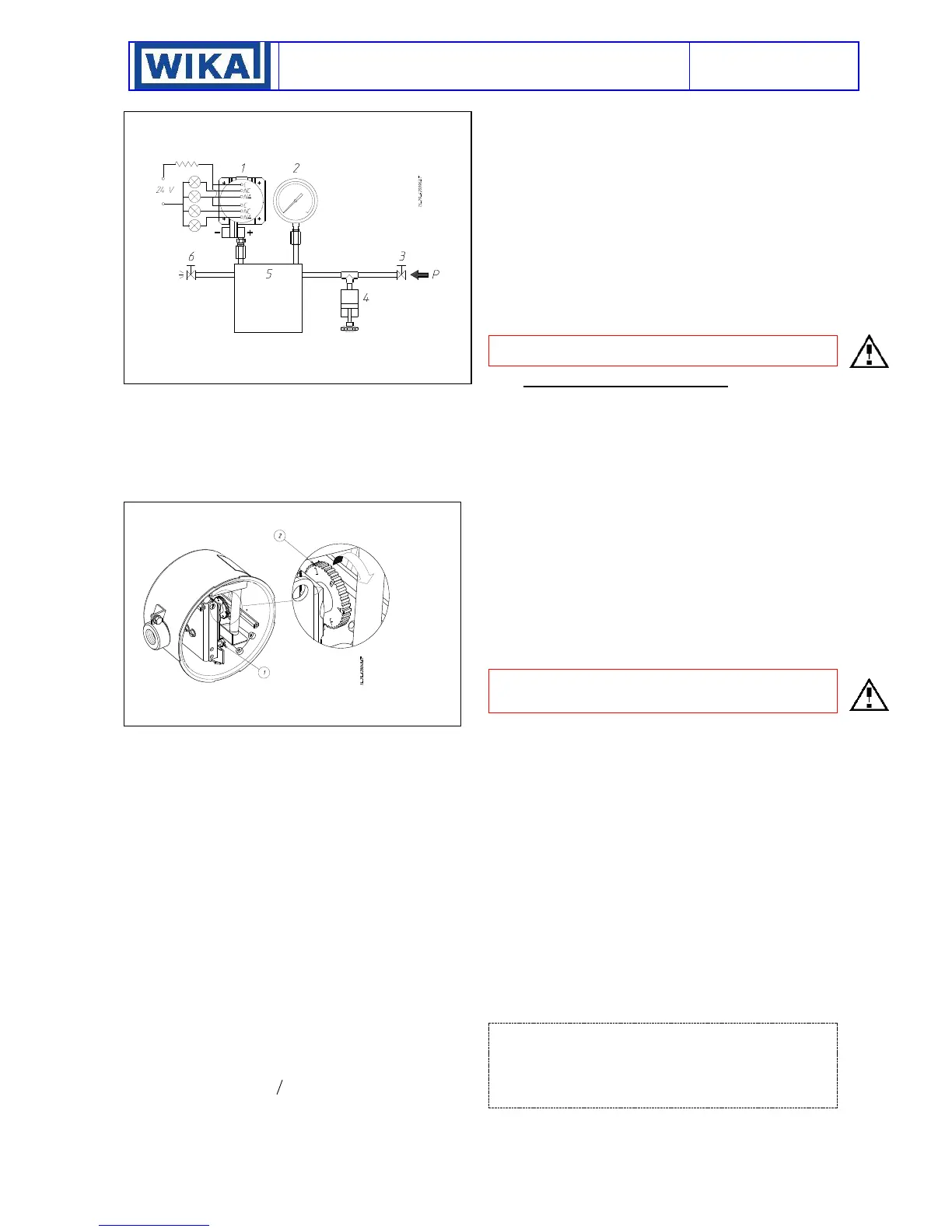

The calibration of the dead band is obtained using the following

procedure:

1 - Raise pressure in the circuit until reaching the set point and

record its value (Pi).

2 - Reduce pressure in the circuit until reaching the reset point

and record its value (Pr).

3 - The difference Pi - Pr = Va represents the dead band factory

adjusted value.

4 - Rotate the adjustment wheel in the sense shown in Fig. 6

placing the red notch in horizontal position

5 - Repeat operations 1 and 2 and measure the new dead band

Vb.

6 - By comparing the values Va and Vb approximately determine

the color of the wheel notch to be placed on the mark.

7 - Place the notch and measure the obtained dead band.

8 - Proceed by successive approximations until reaching the

desired dead band value with enough accuracy.

9 - Then proceed with the set point calibration

Example: The dead band increase corresponding to the rotation

from A to B is given by: Vb - Va =I

The desired dead band V will be approximately in the position

indicated by the value

which expresses:

- By units, the wheel notches (1=one black notch, 2=one red

notch, 3=one yellow notch, 4=one blue notch, 5=one green

notch, 6=two black notches).

- By decimal digits, the percentage middle position between

the located notch (of units) and the following one.

6.6 FINAL OPERATIONS

Disconnect the instrument from the calibration circuit.

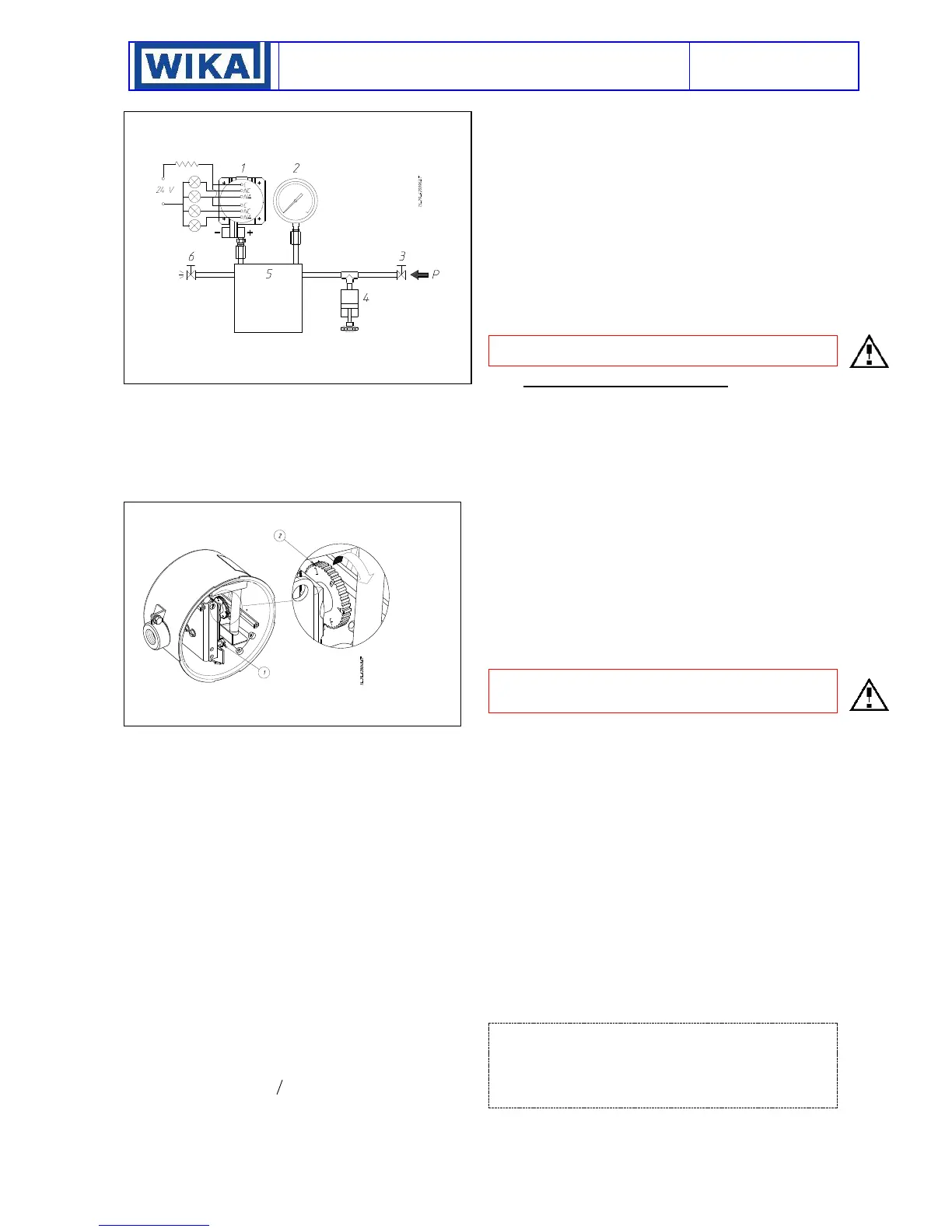

1.1.1 Weatherproof pressure switches (Models DW)

Take the cover, ensure that the sealing gasket is correctly fitted

into its seat, and insert the cover onto the case, with the blocking

gap positioned in correspondence to the blocking bracket.

Turn the cover clockwise closing it tightly. Mount the blocking

device as in Fig. 4. Mount on pressure connection and cable

entry the protection caps supplied with the instrument.

1.1.2 Flameproof pressure switches (Models DA).

Insert the closure plugs of the adjustment screw access holes,

block them using the internal device and if necessary seal them

with plumbing. Screw on the cover and block it using the

headless screw with which it is equipped (Fig. 5)

1.1.3 Final operations

Mount on pressure connection and cable entry the protection

caps supplied with the instrument.

Caution: The protection caps should only be definitively

removed during the connection steps (see § 7).

7. MOUNTING AND CONNECTIONS

7.1 MOUNTING

Surface mount the instrument by means of the holes provided,

or pipe mount using the appropriate bracket (see Fig. 14,15 e

16). In case of surface or panel or rack mounting the instruments

can be mounted side by side (see Fig.19).

The chosen position must be such that vibrations, the possibility

of shocks or temperature changes are within tolerable limits. With

gas or vapour process fluid, the instrument must be positioned

higher than the pipe inlet (see Fig.18). With a liquid process fluid,

the instrument can be positioned higher or lower, indifferently

(see Fig.17 e 18).

7.2 INSTRUMENT WITH DIAPHRAGM SEALS

When the pressure switch is mounted on diaphragm seal with

capillary and the set point is less than 10 bar, the gap (distance

h) between one diaphragm seal and instrument or between the

two diaphragm seals generates a column of liquid, whose

pressure equivalent constitutes a drift of set point. The set point

has to be adjusted consequently.

7.3 PRESSURE CONNECTIONS

Connecting lines are an integral part of the instrument in

transmitting the measured variable from the measuring point to

the instrument.

For a correct installation it is necessary to:

Mount a shut-off valve with drain (root valve) on each process

pipe inlet to allow the instrument to be excluded and the

connection tubing to be drained. It is recommended that said

valve has a capstan blocking device aimed at preventing it being

activated casually and without authorisation.

Mount a 3 valve manifold near the instrument to permit possible

functional verification on site and removal of the instrument. It is

recommended that the manifold is made up of two service valves,

one by-pass valve and two suitably connected drain plugs. The

three valves with the drains can be reunited by a single device

called a “Three valve manifold” (see fig.21 for flanged manifold

valve and fig.22 for direct manifold valve).

Mount a three piece joint onto the threaded attachment of the

instrument to permit the easy mounting or removal of the

instrument itself.

Carry out the connection using a flexible tube in such a way that

variations in the temperature of the tube itself do not force the

instrument attachment.

Ensure that all the pressure connections are airtight. It is

important that there are no leakage in the circuit.

Close root valves, the two service valves, drain plugs and open

the by-pass valve.

NOTE: if the instrument is used for level control in tanks under

pressure it is recommended that installation is carried out

according to the diagram in figure 23 and 24

In case of installation as per fig 23 ensuring that the seal pot B

has a sufficient capacity to maintain the liquid level at the

maximum height over time.

Loading...

Loading...