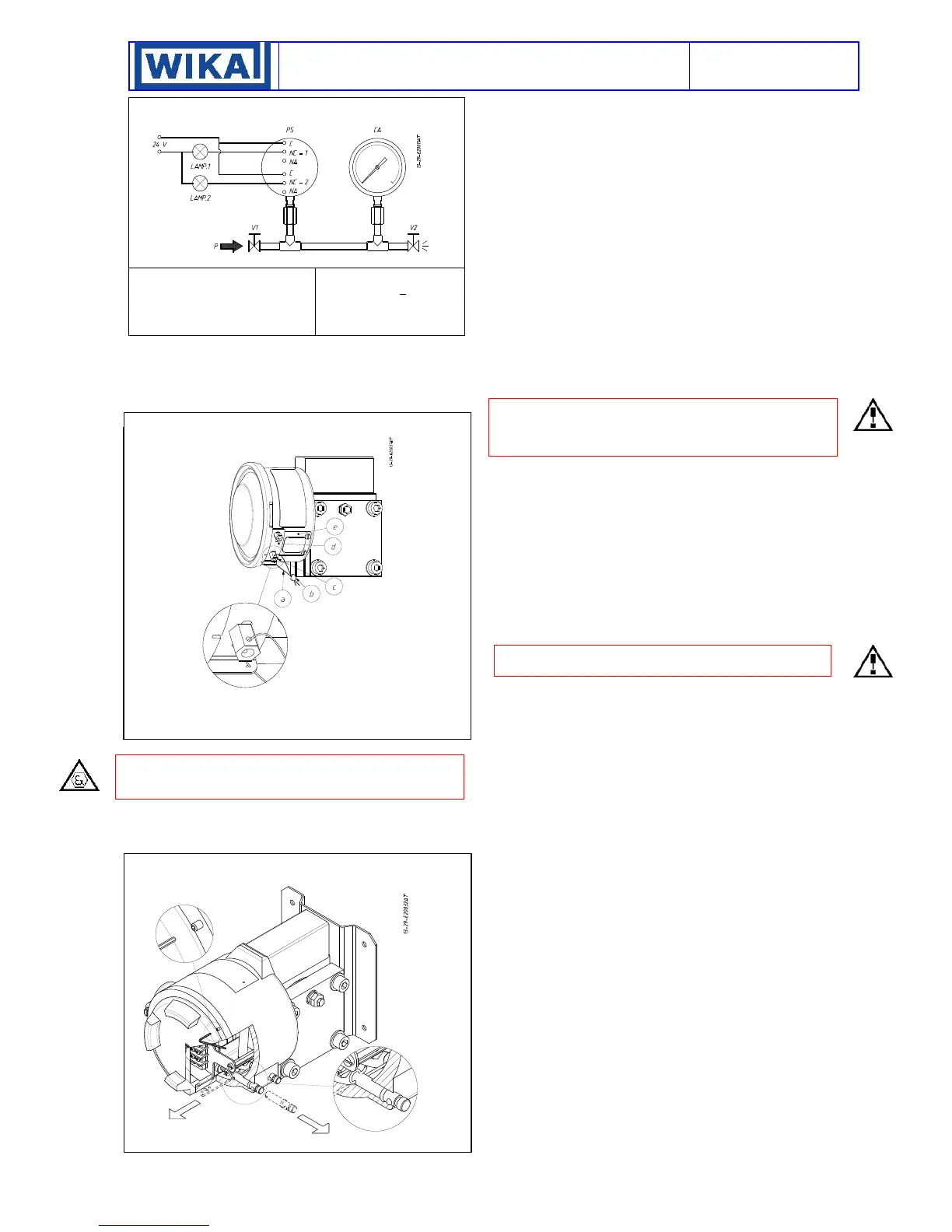

6.2 CALIBRATION CIRCUIT AND OPERATIONS

Prepare the calibration circuit as indicated in Fig.3.

The warning lamps should be connected to contact 1 or 2 in the

NO or NC position according to the required contact action.

Connection of C and NO terminals

• If the circuit is open at the working pressure, the switch closes

the circuit as the pressure increases when the desired value is

reached.

• If the circuit is closed at the working pressure, the switch opens

the circuit as the pressure decreases when the desired value is

reached.

Connection of C and NC terminals

• If the circuit is closed at the working pressure, the switch opens

the circuit as the pressure increases when the desired value is

reached.

• If the circuit is open at the working pressure, the switch closes

the circuit as the pressure decreases when the desired value is

reached.

The pressure switch must be mounted in the normal installation

position, i.e. with the pressure connection pointing downwards.

Avoid forcing the elastic support of the microswitch by hand or

with tools. This could affect the instrument functioning.

CAUTION: if the switch is of the kind with adjustable dead band

(letter R in the contact codes) before proceeding with the

following operations it is necessary to proceed with the

adjustment of the dead band.

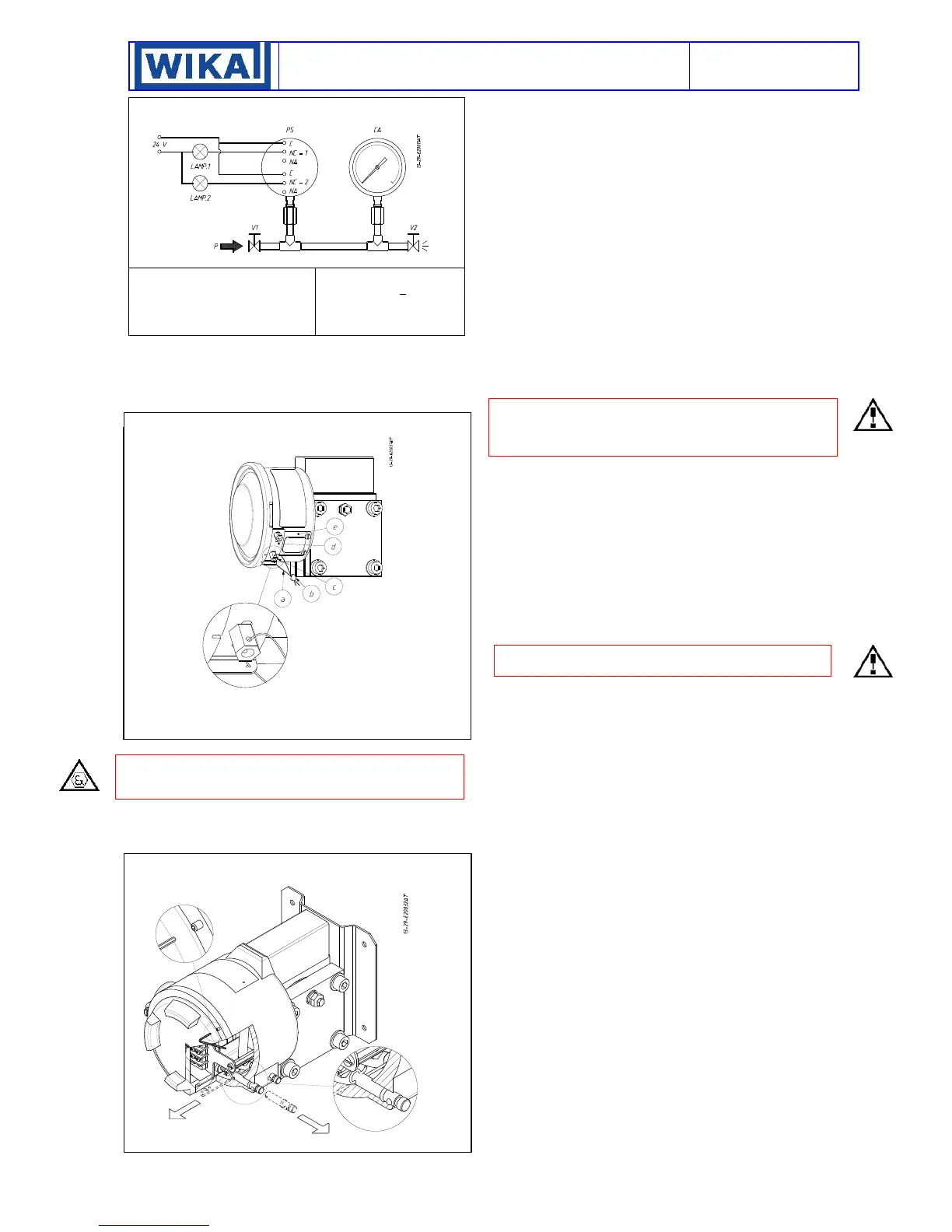

Increase the pressure in the circuit up to the desired set point

value for the first microswitch. Use a wide bladed screwdriver, as

indicated on the label, turn the screw until the relative lamp turns

on (or turns off).

- If the instrument is equipped with only one contact the

calibration is complete.

- If it is equipped with two contacts continue in the following

manner. Vary the pressure until the desired set point value for

the second microswitch is reached. Act on the adjustment screw

of the second contact.

Repeat calibrating operations on the first contact, then on the

second contact, until the required set point accuracy is obtained.

This is necessary due to the reciprocal influence which the

microswitches have on the sensitive element of the instrument.

CAUTION: if the two set point are different they must be different

for much of 5% of the adjustable span.

6.3 CHECK OF SET POINT

Generate the normal working pressure and wait the pressure

stabilisation. Vary the pressure into the circuit and record the set

point value. Write the set point values on the adhesive label.

Note: the repeatability should be checked verifying for three

times the set point (Pi) starting always from the same pressure

value (Pw). The pressure cycle should be slowly to give the

possibility to record the set point with accuracy.

6.4 CALIBRATION CIRCUIT FOR INSTRUMENT WITH

ADJUSTABLE RANGE LESS TO 60 mbar

The calibration circuit used for the calibration of these

instruments must be:

- of big internal volume (5 liters or bigger) in order to reduce the

effect of volumetric variation (and therefore of pressure) caused

by the sensing element of the pressure switch during the snap

action.

- in a thermally stable place in order to guarantee stability to the

pressure inside the circuit used for the calibration.

Have to be considered that in a closed circuit with the internal

pressure equal to the atmospheric pressure, the variation of

temperature of 1°C causes in the circuit a pressure variation of

3,4 mbar.

The maximum inlet pressure must not exceed the lesser of

overpressure allowed by the pressure switch and the test gauge.

The test instrument should have a measurement range

approximately equal to or slightly wider than the pressure switch

range and should have an accuracy consistent with the accuracy

required to calibrate the set point.

For example DW10 range 0..16mbar the accuracy of the test

gauge must be ± 0,04 mbar to calibrate the set point with an

accuracy of ± 0,16 mbar (1% of the adjustable span).

Loading...

Loading...