5 of 9

7.4 INSTRUMENTS WITH PROCESS CONNECTION

COATED WITH PTFE

The pressure connection must be made in such a way that the

part protruding from the instrument have to be used as a sealing

ring.

Fig.8 - Instrument with process connection coated with PTFE

7.5 ELECTRICAL CONNECTIONS

It is recommended to carry out the electrical connections

according to the applicable standards. In case of flameproof

instrument see also the Standard IEC-60079-14. If the electrical

connection is carried out in a protected tube, it shall be made so

that condensate is prevented from entering instrument enclosure

To guarantee the ingress protection IP66 and prevent loosening

of the blocking joint or cable glands, it is prescribed to seal the

threads with an anaerobic sealant. For example, use a sealant

like Loctite ® 542.

CAUTION: fittings used for the electrical connection of the

flameproof instruments shall be certified according the IEC or EN

standards and shall guarantee instrument degree of protection

(IP66).

In the case of Gk threads, this is made in accordance with

standard UNI-EN 60079-1 (Italian national variant).

The installation of the cable gland or three-piece joint should be

as per fig 9.

Fig. 9 – Installation of electrical connection

With the instrument into the final position provided that the

electric line is not energize, remove the cover and make the

electrical connection to the terminal block (see Fig. 2).

If the ambient temperature exceeds 60 °C is recommended to

use cables suitable for operating temperatures of at least 105 °C.

Flexible cables with a maximum section of 1,5 mm

2

(16AWG) are

recommended using the pre-insulated crimp ring terminal.

Do not touch the adjustment screws and do not bend the

elastic microswitch supports in order to prevent the instrument

calibration being altered. Ensure that no deposits or wire ends

remain inside the case.

Warning: The instrument may be equipped with one or two micro

switches SPDT type. All the electrical connection must be part of

intrinsically safe circuits. The relevant parameters for intrinsic

safety are listed on the nameplate of the instrument.

The tightening of the cable gland or the three-piece joint must be

performed as shown in Fig. 10.

Fig. 10 – Installation of the cable gland

As soon as connection steps are completed, mount the cover on

and make sure it is tight and blocked See fig 4 and 5.

7.5.1CONNETTOR 7 POLES TYPE MIL-5015 FOR WEATHER

PROOF INSTRUMENT

The free connector, supplied with the instrument, is able to

accept multicore cables with maximum outer diameter 11 mm. It

is recommended flexible cables with single-conductor with a

maximum section of 1.5 mm2 (16AWG).

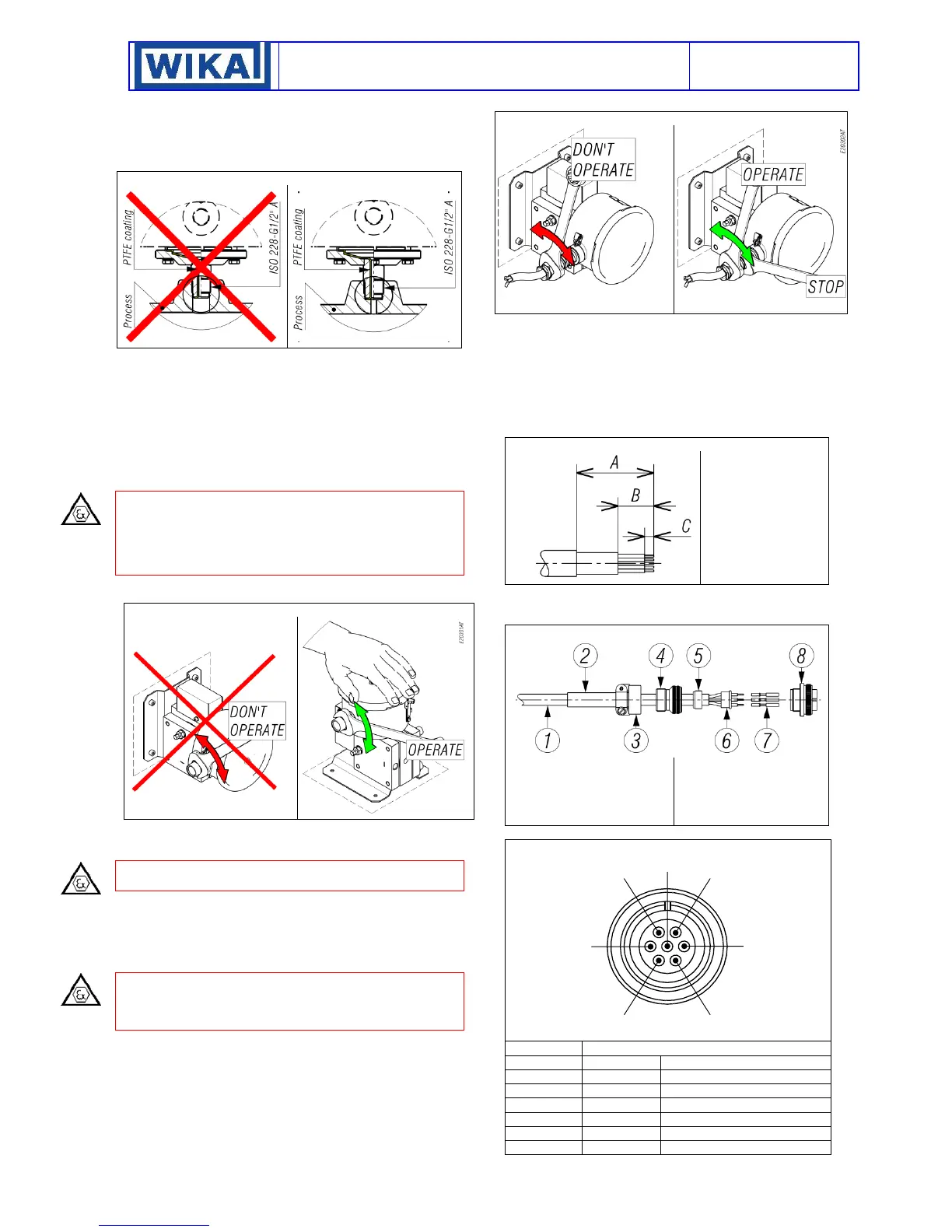

The cable have to be prepared as per fig. 12

Fig. 12 – Cable preparation

A= 53mm

B= 30mm

C= 6,5 mm

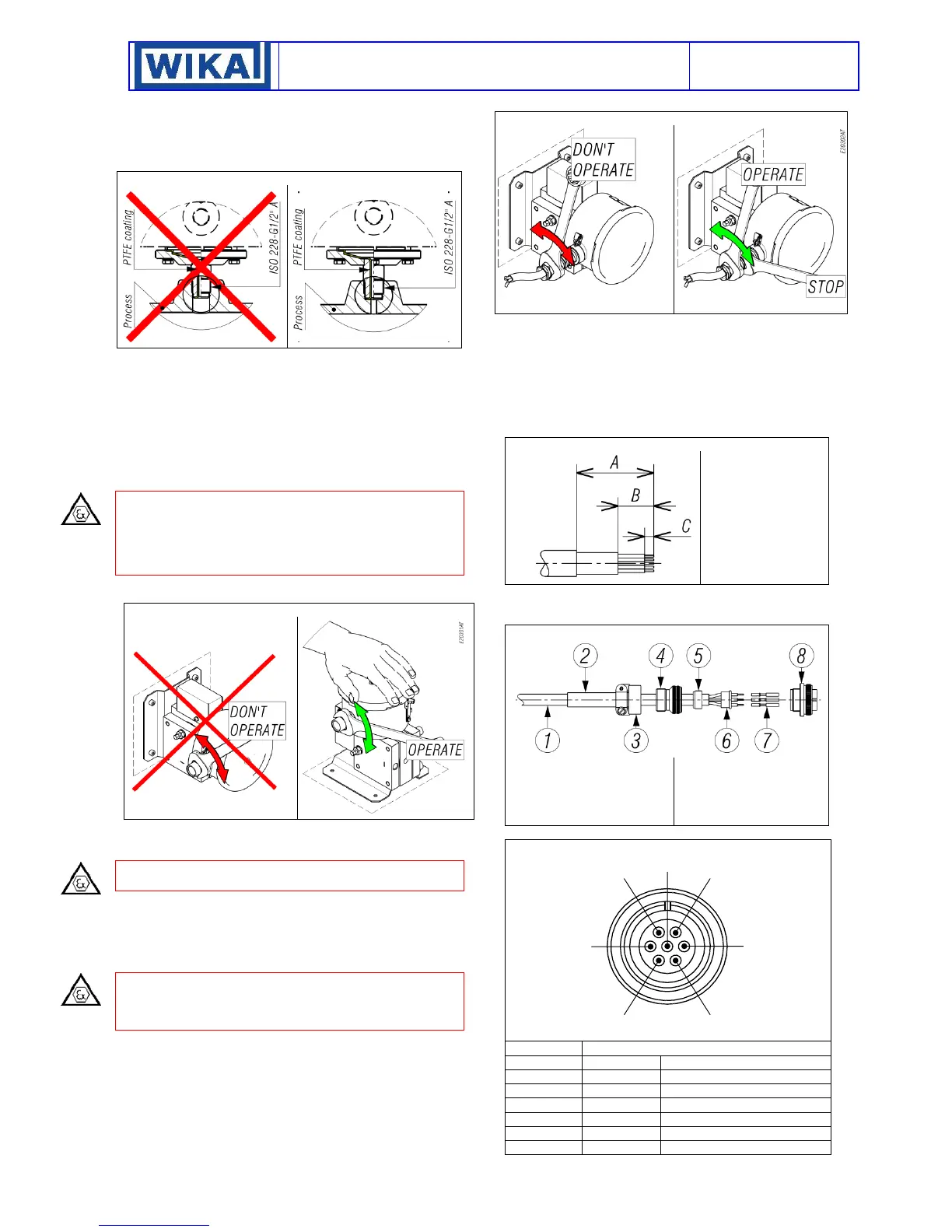

The single stripped conductor has to be crimped with each

contact pin. For the electrical connections and for the assembly

follow Fig.13.

Fig. 13 – Free connector assembly

1- Cable

2- Heat Shrink Boot

3- Clamp

4- Extender

5- Ferrule

6- Insulator for pin

contacts

7- Pin contacts

8- Shell

The wiring diagram is according Fig.14.

Fig. 14 – Wiring diagram MIL C-5015

Internal grounding connection

Once the crimping and assembly activities of the free connector

are finished, make sure that all the parts are tight. Screw the

Loading...

Loading...