2 of 9

1. GENERAL NOTES

1.1 FOREWORD

The wrong choice of a models or a version, as well as the

incorrect installation, lead to malfunction and reduce instrument

life. Failure to follow the indications given in this manual can

cause damage to the instrument, the environment and persons.

1.2 ALLOWED OVERRANGE

Pressures exceeding the working range can be occasionally

tolerated provided they remain within the limits stated in the

instrument features (vacuum or proof pressure). Continuous

pressures exceeding the working range can be applied to the

instrument, provided they are clearly stated in the instrument

features. The current and voltage values stated in the technical

specifications and ratings must not be exceeded. Transitory

overranges can have a destructive effect on the switch.

1.3 MECHANICAL VIBRATIONS

Can generally lead to the wearing of some parts of the instrument

or cause spurious action. It is therefore recommended that the

instrument be installed in a place where there are no vibrations.

In cases where this is impossible it is advisable to take measures

to lessen the effects (elastic supports, installation with the pin of

the microswitch positioned at right angles to the vibration plane,

etc.).

1.4 TEMPERATURE

Due to the temperature of both the environment and the process

fluid, the temperature of the instrument could exceed the allowed

limits (normally from -40° to +60°C). Therefore, in case it does,

suitable measures (protection against heat radiation, fluid

separators, cooling coils, heated lockers) must be taken. The

process fluid or its impurities must not in any case solidify inside

the instrument chambers

2. OPERATING PRINCIPLE

The differential pressure, acting on the sensitive diaphragm

element, determines its elastic deformation which is used to

actuate one or two electric microswitches adjusted at set point

values. The microswitches are of the snap acting type with

automatic reset. When the pressure moves away from the set

values, returning towards the normal values, the switch is reset.

The dead band (difference between the set point value and the

reset value) can be set or adjustable (letter R in the contact

codes).

3. MODEL CODE

See Annex 1

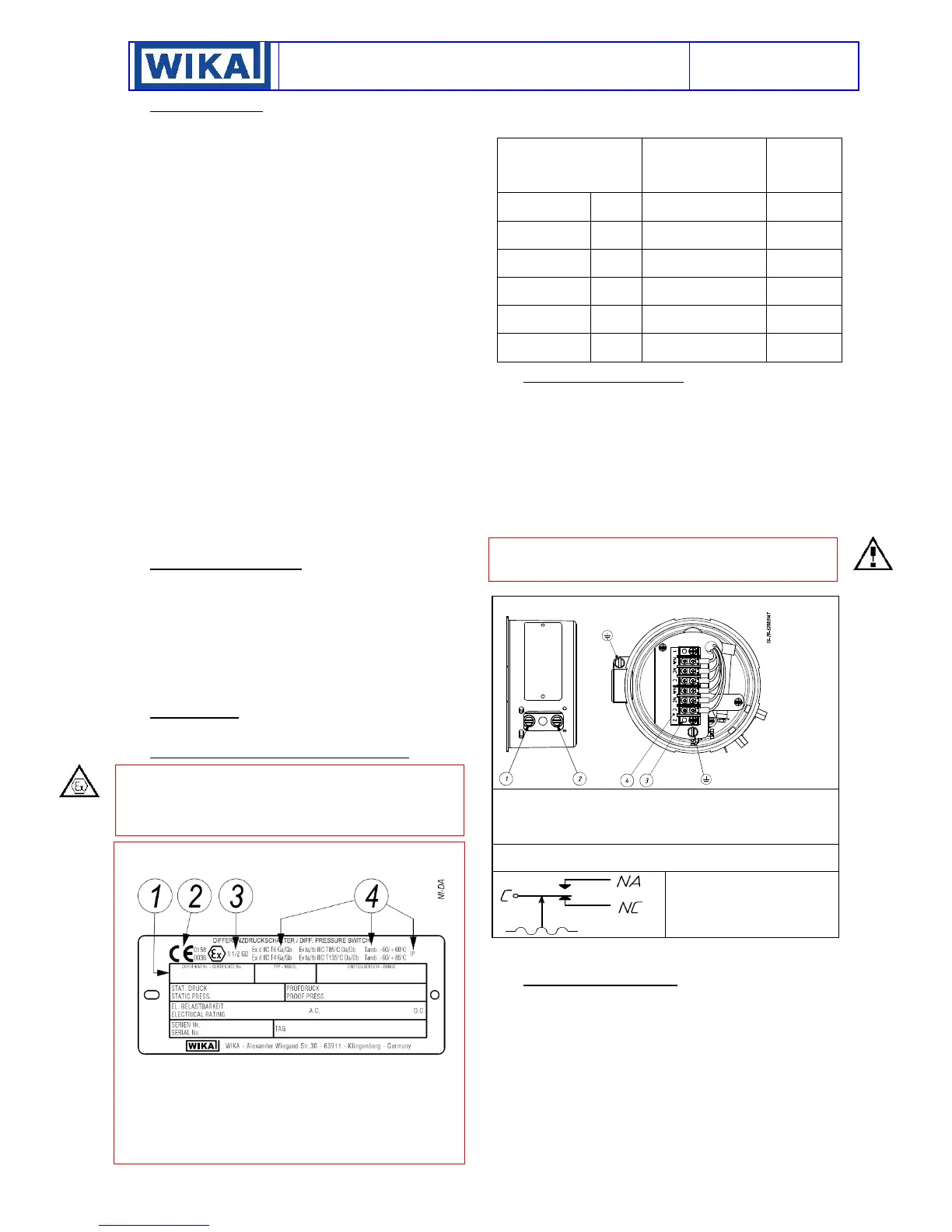

4. IDENTIFICATION PLATE AND MARKINGS

The instrument is fitted with a metal plate bearing all its functional

characteristics and in case of flameproof or intrinsic safety

execution also the markings prescribed by standard IEC/EN

60079-0. Fig.1 shows the plate mounted on flameproof

instruments.

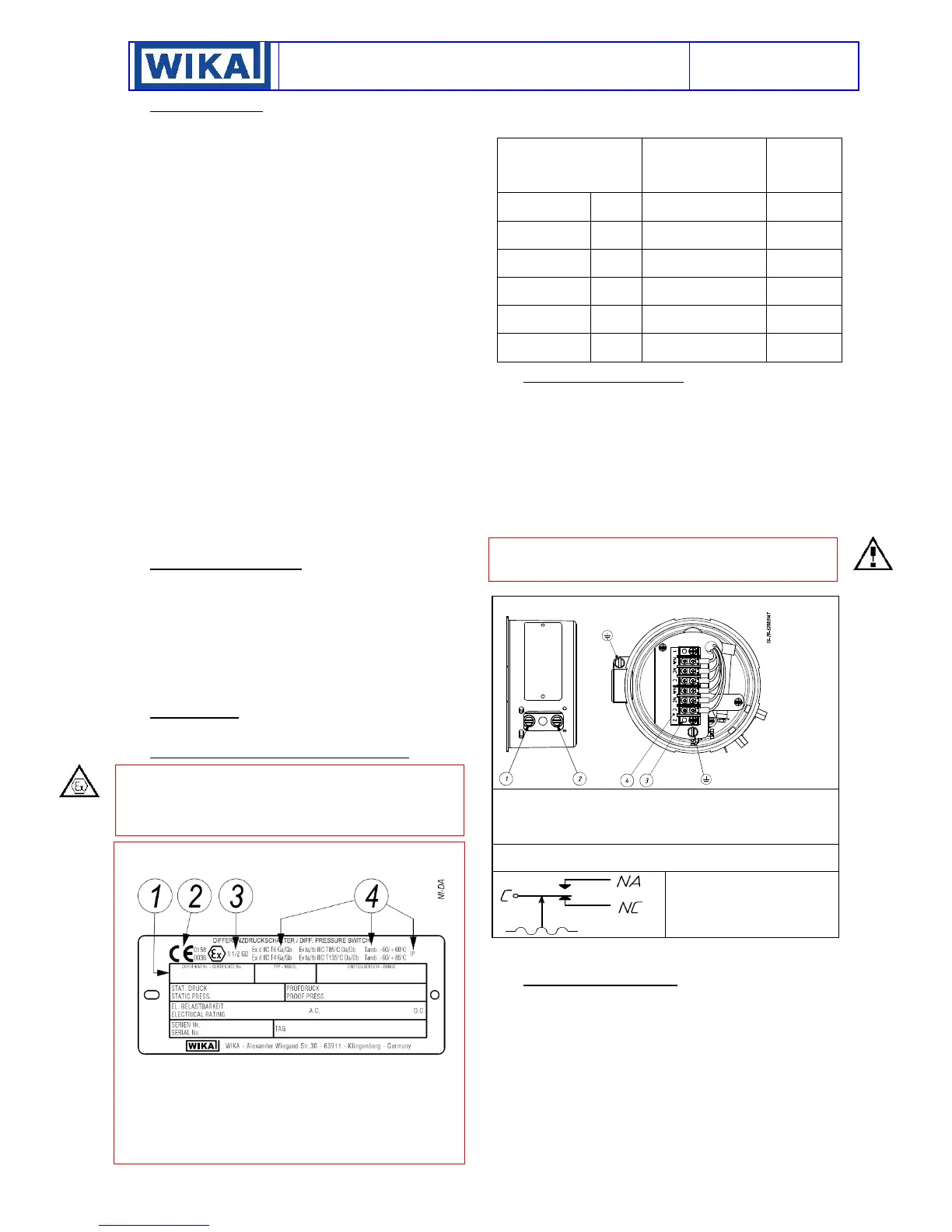

5. SET POINT REGULATION

Each microswitch is independent and can be adjusted by means

of a screw (for adjustment) to snap when the pressure reaches

(increasing or decreasing) the desired value (set point). The

instrument is usually supplied with the switches adjusted at the

setting range value nearest to zero (factory calibration). The

instrument is supplied with a label showing the set point

calibration value. With factory calibration the values are not

indicated, as these are temporary and will be modified with the

definitive values. Prior to installation the instrument must be

calibrated and the definitive calibration values written on the

label.

If the instrument has been ordered with a specific calibration,

check the calibration values marked on the relevant label, prior

to installation.

The position of the adjustment screw is given in figure 2.

The effect that the direction of rotation of the adjustment screw

has is described on the label.

6. SET POIT CALIBRATION

In order to proceed with the calibration and the periodical

functional verification of the instrument a suitable calibration

circuit (Fig. 3) and an adequate pressure source is required. The

test instrument should have a measurement range approximately

equal to or slightly wider than the pressure switch range and

should have an accuracy consistent with the accuracy required

to calibrate the set point.

Loading...

Loading...