0300-46

LVILI.YS hlODEL

"MB"

%-TON

4

x

4

GOVERNMENT

TRUCK

If

tlie c;irliiiretor bore

is

restricted witli carboii

dcp<)sit it wil1 I>e iieccssary to open tlie tlirottle

wiqlcr tliaii tlic spccili<!d cipciiiiig to obtaiti tlie

~lroper idle speed. Ol>ciiirig tlie tlirottle inore

tliaii tlie specified aiiioirnt in order to obtaili tlie

proper idle wil1 tlieii iiricover more of tlie slotted

idle port tliaii was iiitctided. Tliis wil1 result in

le;ivitig an iiisiillicient nniount of tlie idle port as

a reserve to cover tlie

pcriod betweeii idle aiid

20

iiiiles per Iioiir. wliere tlie Iiigli speet1 system Iie-

giris to cut in.

I\

Ilnt spot on acceleration wil1

resiilt. Clcaii I>y scrapiiig or witli eniery clotli.

Iligli Speed Circuit

It is rarely iiecessary to remove Llie inain iioazle

No.

20,

Fig.

5.

It cari usiially

11e

cleaned by re-

nioviiig plug aiid blowiiip: out witli compressed air.

If it is daiiiagcd ancl rcqiiires replacing make sure,

upuil installatioii. only olie gaskct is between noazle

aiid its sent

iii

tlie casting.

If tlie carbtiretor lias I>eeri in service lor

a

loiig

titiie or Iias bceii taiiiliere<l witli, it niay be found

tlie

tneteriiig rod is iiiiproperly adjusted or worii.

A

worri ineteriiig rwl will have tlie effect of a ricli

mixture ahuve

20

niilcs lier Iiour. If the meteririg

rod

is

worii.

tlir

iiietcriiig rod jet wil1 also be worn

aiid

botli slioiild bc rc1)laced.

'I'o

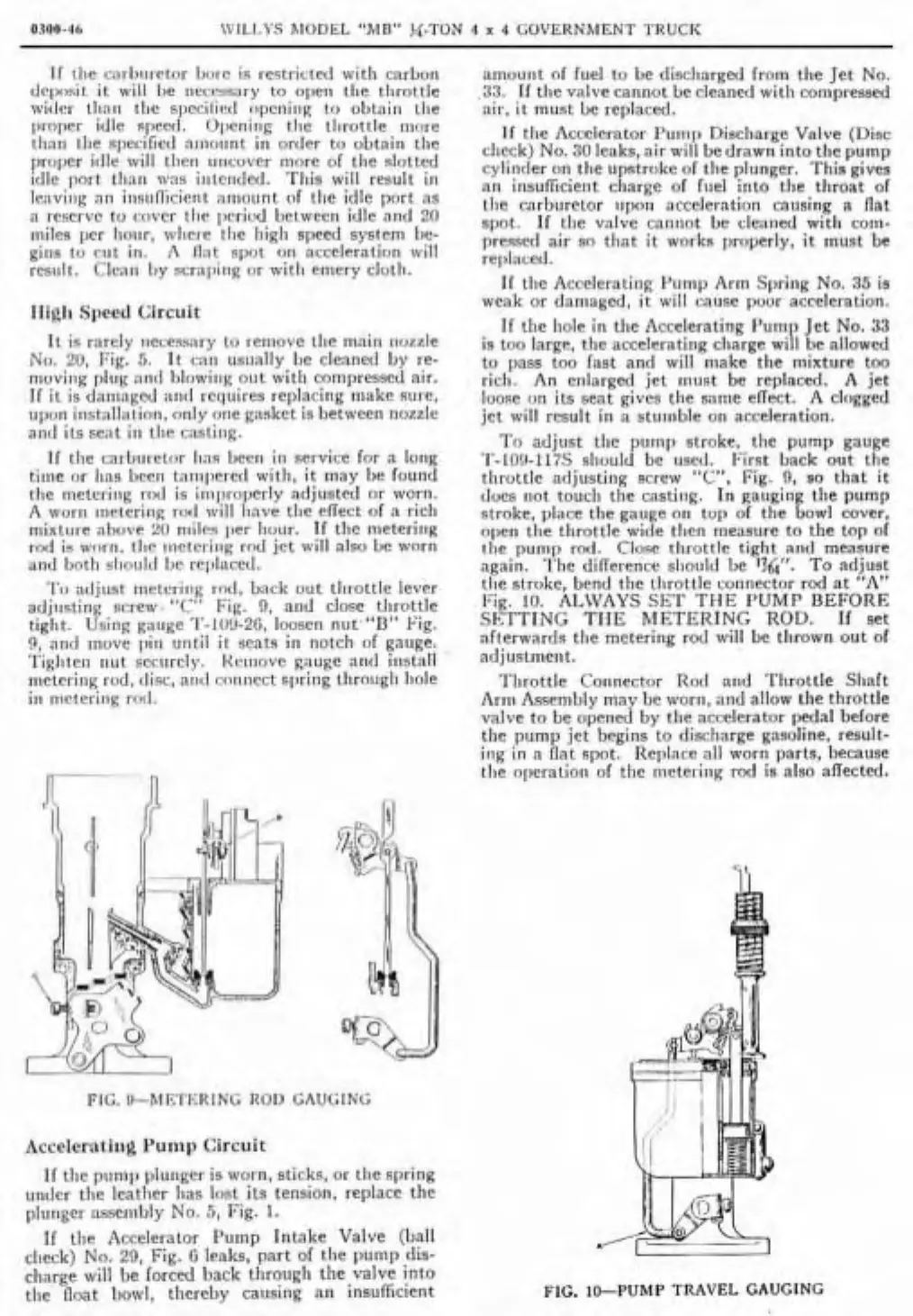

adjiist iiietciiiig I<K~, back out tlirottle lever

adjiisting

screw.

"C"

Fig.

9.

aiid close tlirottle

tiglit. Using gauge

'1'-10!l-26.

loosen nut."D" Fig.

9.

arid rnove

11iti

iintil it scats in iiotch of gai1p:e.

'l'i~literi ~iut sc<:iirely.

I<ciriove gauge and iiistall

nicteririg rod,

(list,

aiiil cr>iiriect spring tlirougli Iiole

i11

nirteriii~ rn~l.

FIG. O-METICRING ROD CAUGING

Accelerntiiig

Pump

Circuit

If

tbe punil~ plunger is worn, sticks, or tlie spring

iin<ler tlie lcatlier Iias lost its tension, replace the

pluriger asseriibly No.

5,

Fig.

1.

I1 tlie Accelerator Pump Intake Valve (ball

clieck) No.

29,

Fig.

G

leaks, part of tlie punip dis-

cliarge wil1 be lorced I~ack througli the valve into

tlie float

IIOIV~, tlierel>y causiiig an insuficient

amouiit of fuel to be discharged from the Jet No.

33.

If the valve cannot be cleaned witli compressed

air. it must be replaced.

If

tlie Accelerator Pump Discliarge Valve (Disc

clieck) No.

30

leaks. air wil1 bedrawn into the pump

cyliiicler on tlie upstroke of tlie plunger. This gives

an iiisuficient charge

of

fuel into tlie throat of

tlie carburetor

iipon acceleration causing a flat

spot.

I1 tlie valve caiiiiot be cleaned witli coin-

pressed air so that it works properly.

it

must be

replaced.

I1 tlie Accelerating i'iimp Arm Spring No.

35

is

weak or darnaged. it

wil1 cause poor acceleration.

If the Iiole in the Accelerating Punip Jet No.

33

is too large. the acceleratirig cliarge wil1 be allowed

to pass too last and wil1 make the mixture too

ricli. An erilarged jet iiiust be replaced. A jet

loose

on its $ent gives tlie same eliect. A clogged

jet wil1 result in

a

stuiiible on acceleration.

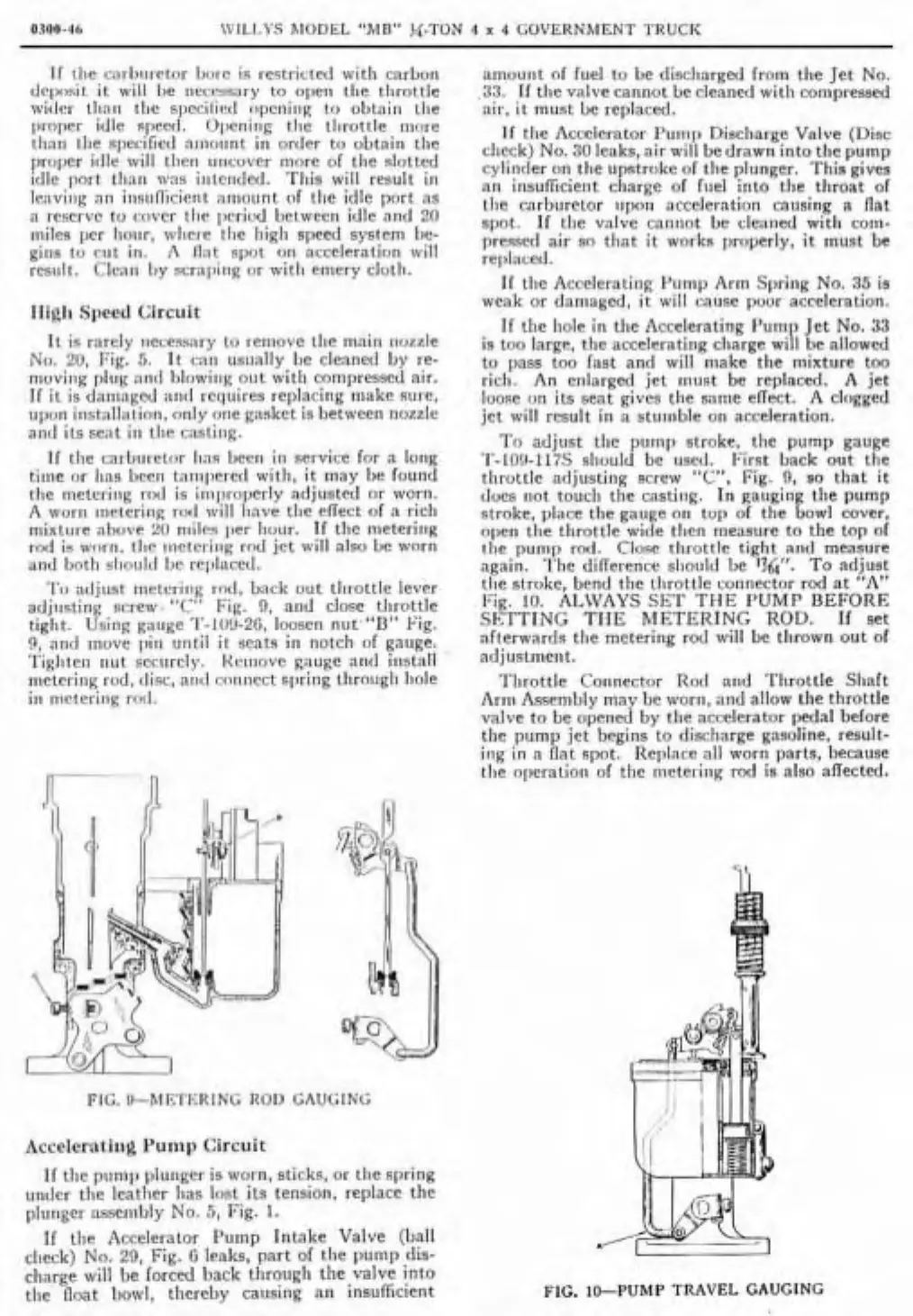

To adjust tlie puin11 stroke. the pump gauge

'I'-109-117s

sliould be iised. First back out tlie

tlirottle

adjusting screw

"C",

Fig.

9,

so that it

docs iiot toucli the castiiig. In gaiiging the pump

stroke, place the gauge on top of tlie bowl cover.

opeii the throttle wicle tlien ineasiire to tbe top of

tlie pump rml. Close tlirottle tiglit anti measure

again. 'ïhe difference slioiild be

'74''.

To adjust

tlie stroke, bend the tlirottle connector rod at

"A"

Fig.

10.

ALWAYS

SET THE PUMP BEFORE

SETTING

TIIE METERING

ROD.

If set

afterwards tlie

metering rod wil1 be tlirown out of

adjiistnierit.

Tlirottle Coiinector Rod and Throttle Cliaft

Ariii Assemlily may be worn, and allow tlie throttle

valve to be

opeiied by tlie accelerator peda1 belore

tlie pump jet begins to

discliarge gasoline, result-

irig in a flat spot. Replnce al1 worn parts, because

tlie operatioii of the iiieteiiiig rod is also affected.

FIG. 10-PUMP

TRAVEL

GAUGING

Loading...

Loading...