WILLYS MODEL

"MB"

M-TON

4

x

4

GOVERNMENT TRUCK

0300-45

Low

Speed Circuit

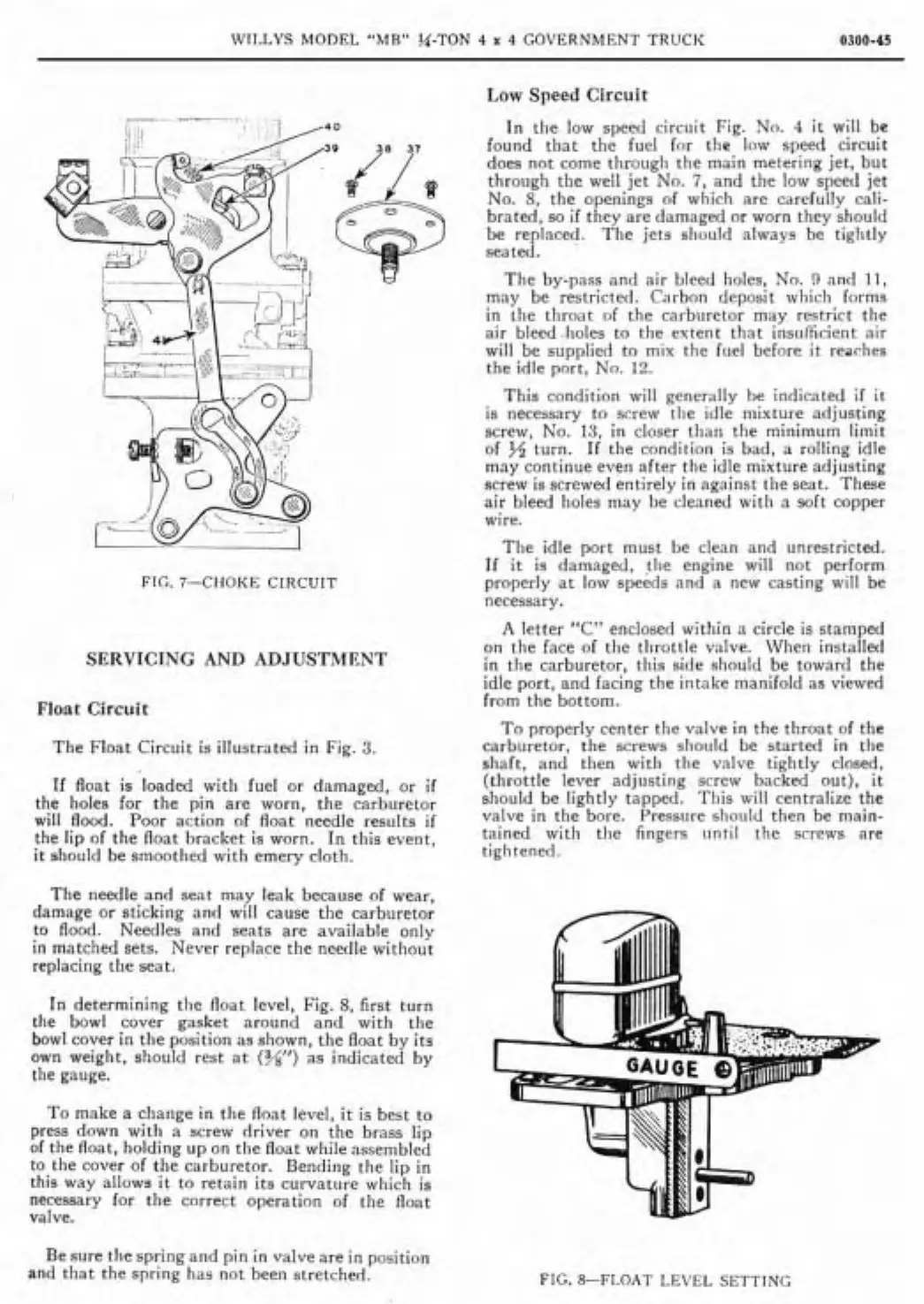

FIG.

7-CHOKE CIRCUIT

SERVICING

AND ADJUSTMENT

Float Circuit

The Float Circuit is

illustrated in Fig.

3.

If

float

is

loaded witli fuel or damaged, or

if

the holes for the pin are worn, the carburetor

wil1 flood. Poor action of float needle results

if

the lip of the float bracket is worn. In this event.

it should be smoothed with emery cloth.

The needle and seat may leak

because of wear,

damage or sticking and wil1 cause the carburetor

to flood. Needles and seats are

available only

in matched sets. Never replace the needle without

replacing tlie seat.

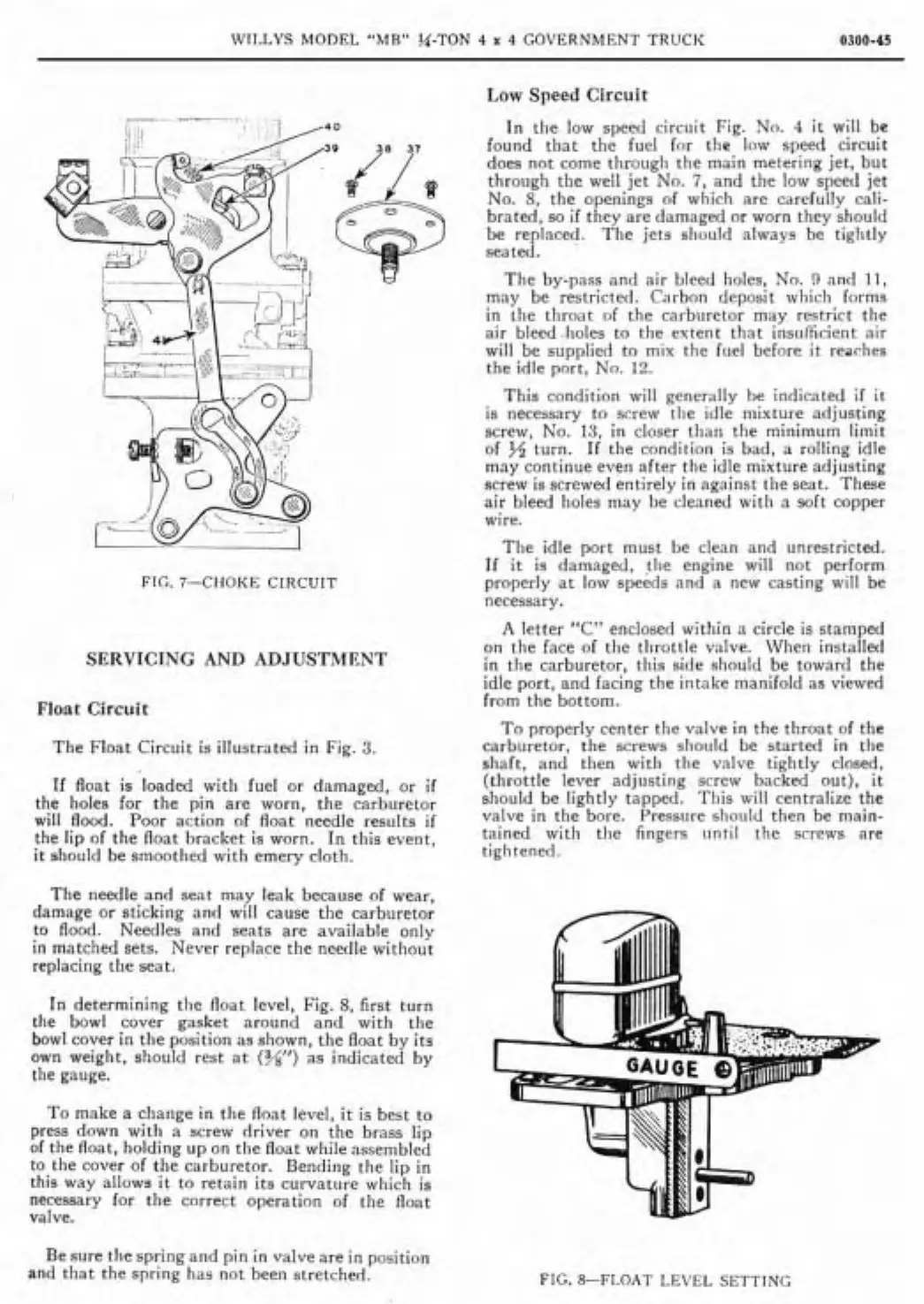

In determining tlie float level, Fig.

8,

first turn

the bowl cover

gasket around and with the

bowl cover in the position as

shown. the float by its

own weight. should rest at

(w)

as

indicated by

the gauge.

To make a change in the float level, it is best to

press down with

a

screw driver on the brass lip

of the float, holding up on tlie float while assembled

to the cover of the carburetor.

Bending the lip in

this way

allows it to retain its curvature which is

necessary for the correct operation of tlie float

valve.

In tlie low speed circuit Fig. No.

4

it will

be

found that the fuel for the low speed circuit

does not

come througli the main metering jet, but

through the

wel1 jet No.

7,

and the low speed jet

No.

S,

the openings of whicli are carefully cali-

brated. so

if

they are damaged or worn they should

be

replaced. The jets slioiild alxvays be tightly

seateù.

The by-pass and air bleed

holes, No.

9

nnd 11,

may be restricted. Carbon deposit which forms

in tlie throat of the carburetor may restrict the

air

bleec.lioles to the extent that insulficient air

wil1 be supplied to mix the fuel before

it

reaches

the idle port, No.

12.

This condition wil1 generally be indicated

if

it

is

necessary to screw tlie idle niixture adjusting

screw, No.

13.

in closer tlian the minimum limit

of turn. If the condition is bad, a rolling idle

may continue even

after the idle mixture adjusting

screw is screwed entirely in against the seat. These

air bleed holes may be cleaned

witli a soft copper

wire.

The idle port must be clean and

unrestricted.

If

it

is damaged, tlie engine wil1 not perform

properly at

low speeds nnd a new casting wil1 be

necessary.

A

letter

"C"

enclosed within a circle is stamped

on tlie face of the tlirottle valve. When

installed

in tlie carburetor, this side should be toward the

idle port, and facing the intake manifold as viewed

from the

bottom.

To properly center the valve in the throat of the

carburetor. the screws slioiild be started in tlie

shaft, and then with the valve tightly

closed.

(throttle lever adjusting screw backed out), it

sliould be lightly tapped. This will centralize the

valve in the bore.

Press~ire sliould then be main-

tained with the fingers iintil the screws are

tiglitened.

Besure thespringand pin in valveare in position

and that the

spring has nor been stretchml.

FIG. &FLOAT

LEVEL

SETTING

Loading...

Loading...