11OPM-109

REV A

Note:Wire#93isenergizedtoturnontheglowplugsfor15seconds

first and then the starter and fuel solenoid are engaged.

If the engine fails to start during this cranking period, the starter motor

is disengaged and goes into a rest mode after which a second attempt

is made to start the engine. Should this sequence continue through 3

cranking cycles the start sequence will be stopped and the display will

show ‘FAILED TO START”.

3. During manual operation, the load will not normally be applied to the

generator. But caution must be used, if the line power should fail or be

turned off the transfer switch during manual operation the load may be

applied to the generator.

With the engine running smoothly check the no load voltage and

frequencyonthedigitaldisplay.Thevoltageshouldbe208/240/480AC

depending on which model you have and a frequency of 59.5 to 60.5

hertz(Hz).

If you have the proper voltage at the generator the next step is to

check the voltage at the generator terminals in the Automatic Transfer

Switch. The voltage between the G1 and the G3 terminals should be

the same as it was on the generator front panel. The voltage should

alsobecheckedbetweenthehotterminals(G1andG3)andtheG-Nto

be certain of a balanced voltage output and a solid neutral connection.

The voltage between G1 and G-N should be about 120 volts AC (277

on480units).Thesameapproximatevoltageshouldbefoundbetween

terminalsG3andG-N(120voltsAC).

On three phase panels the G2 voltage level should also be checked.

ON240VOLT(DELTA)SYSTEMSBESUREYOUKNOWWHERE

THE HIGH VOLTAGE “WILD” LEG IS. IT MUST BE IN THE SAME

LOCATION ON THE LINE SIDE AS IT IS ON THE GENERATOR SIDE.

(i.e. if it’s on L-3 on the line side it must be on G-3 on the generator

side. Also on three phase systems make sure that the rotation

is the same on the generator as it is on your line power. Failure

to insure proper rotation will cause three phase motors to spin

backwards possibly damaging them.

NOTICE:

If for any reason during the check out procedure the voltage and

frequency are not correct, depress the STOP/RESET button and

correct the trouble before proceeding.

4. Stopping - There are two ways to stop the unit when it is in the

manualmode.PressingtheSTOP/RESETbuttonwillstoptheunit

immediately. Pressing the AUTO mode button will stop the unit but only

after the cool down timers have timed out and there is no remote start

signal being sent to the unit.

AUTO MODE

To activate the automatic start mode you will just need to depress the

AUTObutton,theLEDindicatorbesidethebuttonconrmsthattheunit

is in automatic mode.

To test the Automatic Transfer Switch, follow the instruction on the

operator’s manual that came with the transfer switch. If you get a fault

during the initial start up or prior to start up, it is most likely a false

warning light. Simply reset the ATS start over.

Once you have completed testing of the ATS, be sure you ALWAYS

leave the system in the standby mode,unless servicing the unit. For

standby operation, press the AUTO button on the front of the control.

The green light should light up next to the AUTO button.

NOTE: For setting the exerciser circuit, for all ATS, see the operator’s

manual shipped with the ATS.

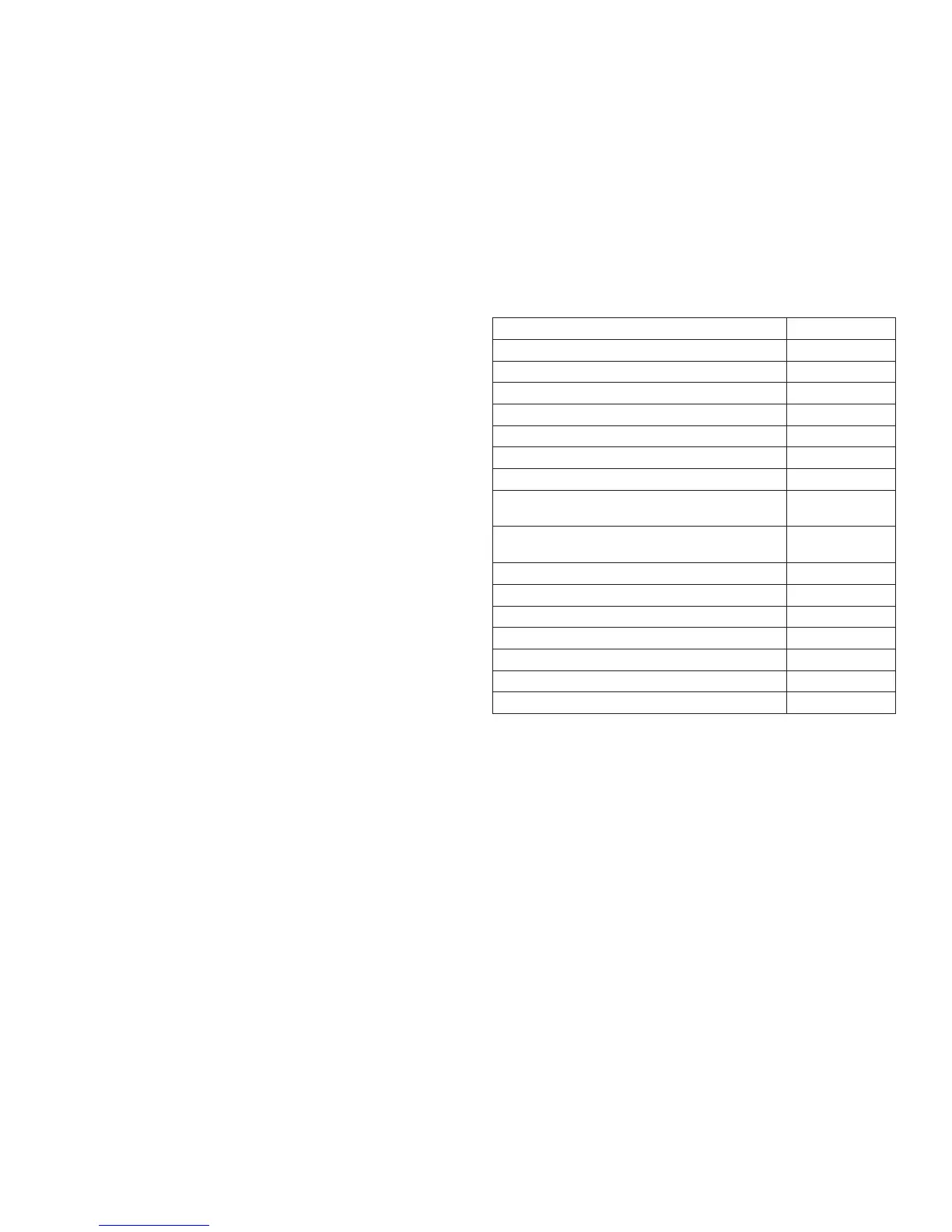

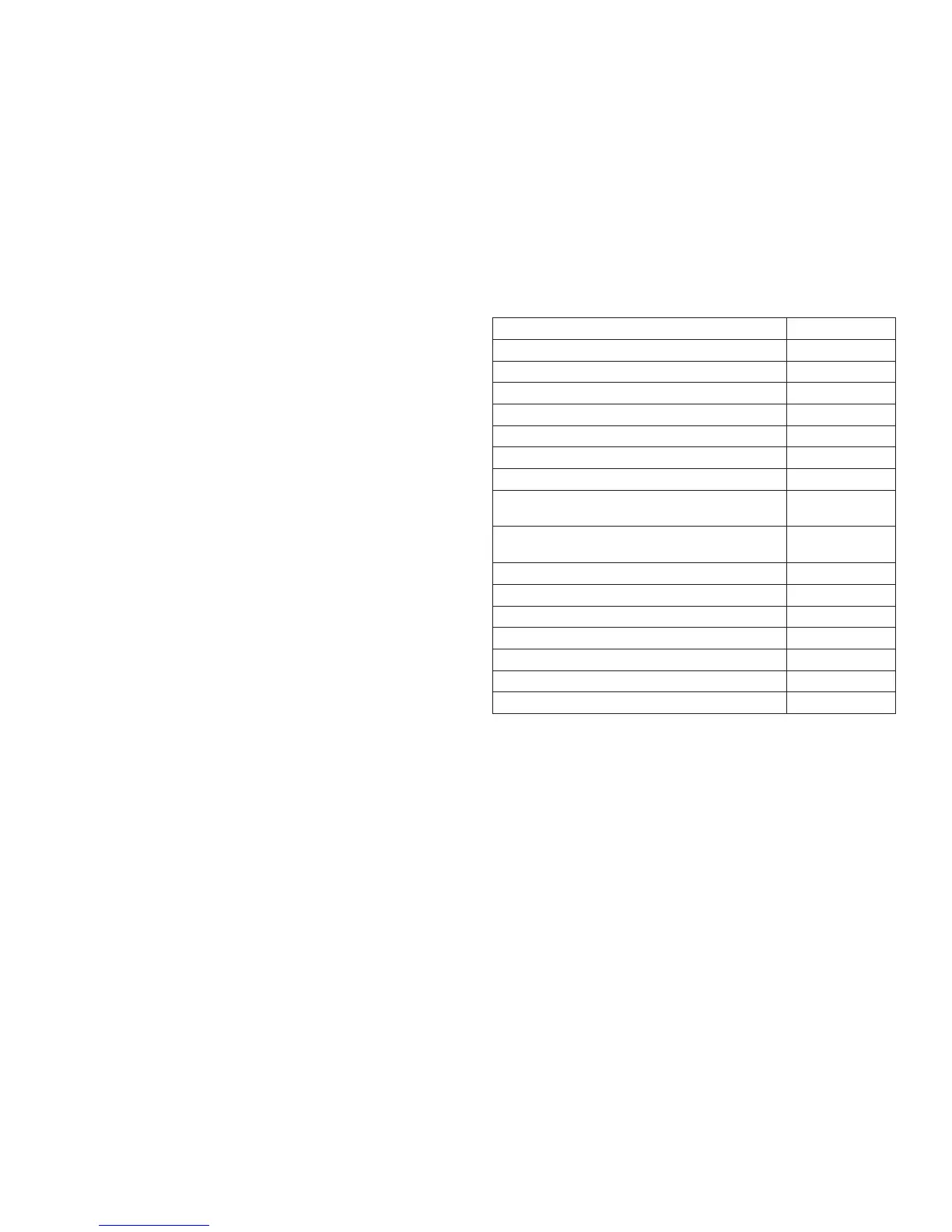

MAINTENANCE SCHEDULE

SERVICE

INTERVALS

Check Engine Oil Level Daily

Check Coolant Level and for Leakage Daily

Check Air Filter Daily

Check Electrolyte Level in Battery and Clean Terminals 90 Days

Drain Water from Fuel Pre-Filter Daily

Check Belts and Belt Tension Daily

Check Preheating Operation Daily

Change Oil - Initial

- After Initial

50 Hours

250 Hours

Change Oil Filters - Initial

- After Initial

50 Hours

500 Hours

Change Fuel Filters 500 Hours

Check Exhaust System for Damage 180Days

Clean Fuel Tank 180Days

ChangeAirFilter(dependingonconditions) 600 Hours

Check Valve Clearance 1000 Hours

Clean Crankcase Ventilation Valve 1500 Hours

ChangeCoolant/CleanSystem 1000 Hours

* There are additional maintenance items and explanations in the

engine operator’s manual. Read thoroughly before operating this unit.

Loading...

Loading...