________________________________________________________________________________________

www.wnt.com XND.00004.023_A - 02/2018 22

Position the stop pin

e.g. when replacing the mechanical force element.

Turn the mechanical force element into the spindle

nut.

Remove the guide component. (pos. 40)

Fit the stop pin (pos. 50) and lightly fix the threaded

pin (pos. 140) but do not lock.

Turn the spindle until the stop pin comes to a stop

at the spindle nut lug.

If this does not happen, turn the stop pin by 180°

and repeat the previous step.

Check that the pin has stopped.

Secure the stop pin with the threaded pin.

Fit the bearing washer, spacing washer and spring

washer. (HDG2 160: 3 instead of 2 spring washers)

Secure the countersink screw with screw lock,

medium tight.

Fit the guide component so that it protrudes on the

jaw side.

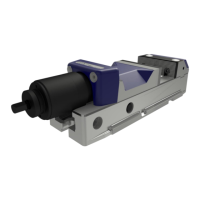

Setting ring does not move

Var. 1: Setting ring turned in too hard

Gap A is approx. 0 mm. To release the setting ring,

turn it anti-clockwise.

Var. 2: Setting ring turned out too much

Gap A is approx. 1 mm. To release the setting ring,

turn it clockwise.

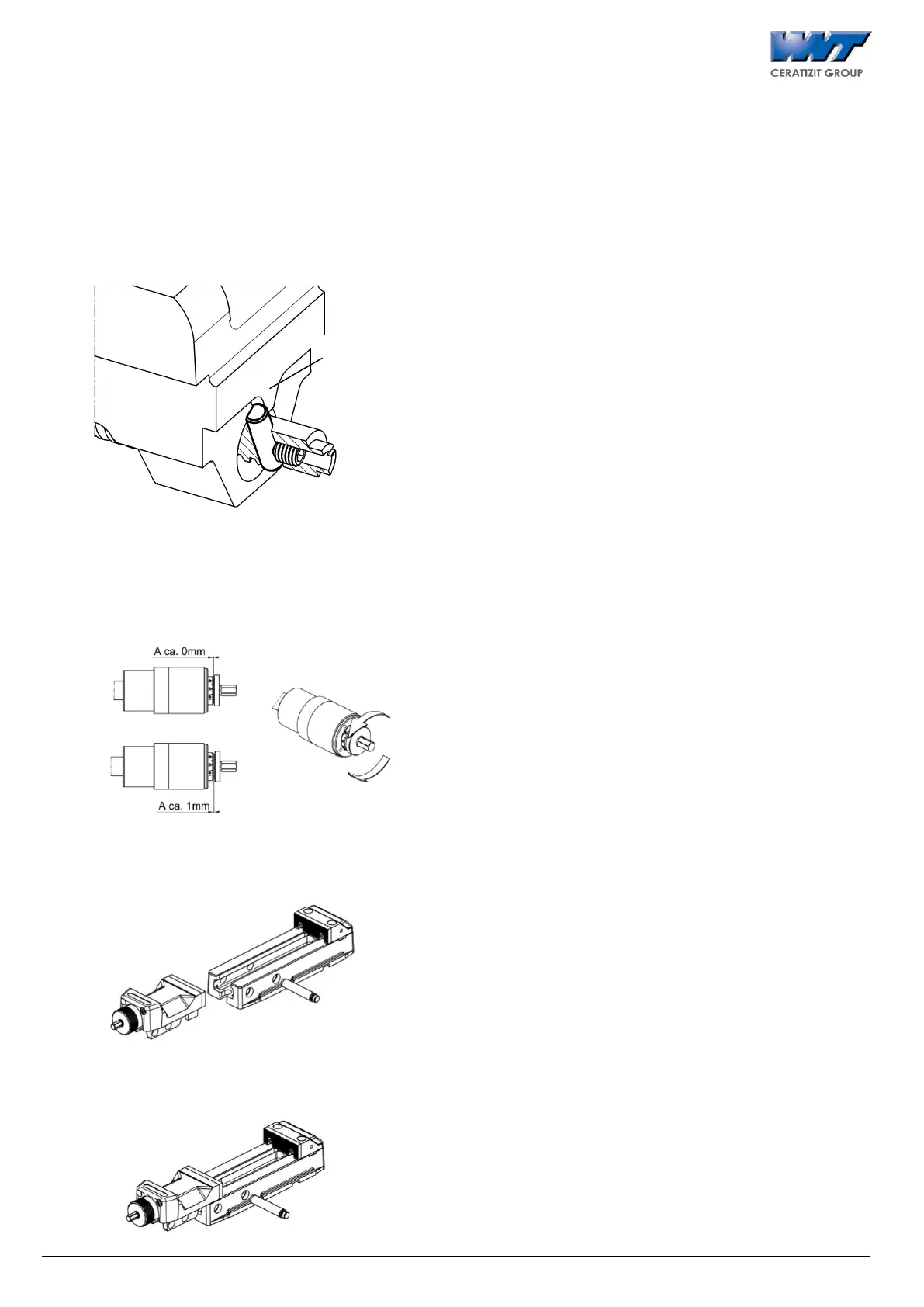

7 Removing and replacing parts

7.1 Removal

Remove locking pin (pos. 60) and move out

carriage.

7.2 Installation

Insert the carriage and then the locking pin (pos. 60)

while adequately lubricating the guides, e.g. using

MOTOREX Supergliss 68 K lubricant to ISO VG 68.

Loading...

Loading...