18 Owner Service

MAN1249 (2/28/2018)

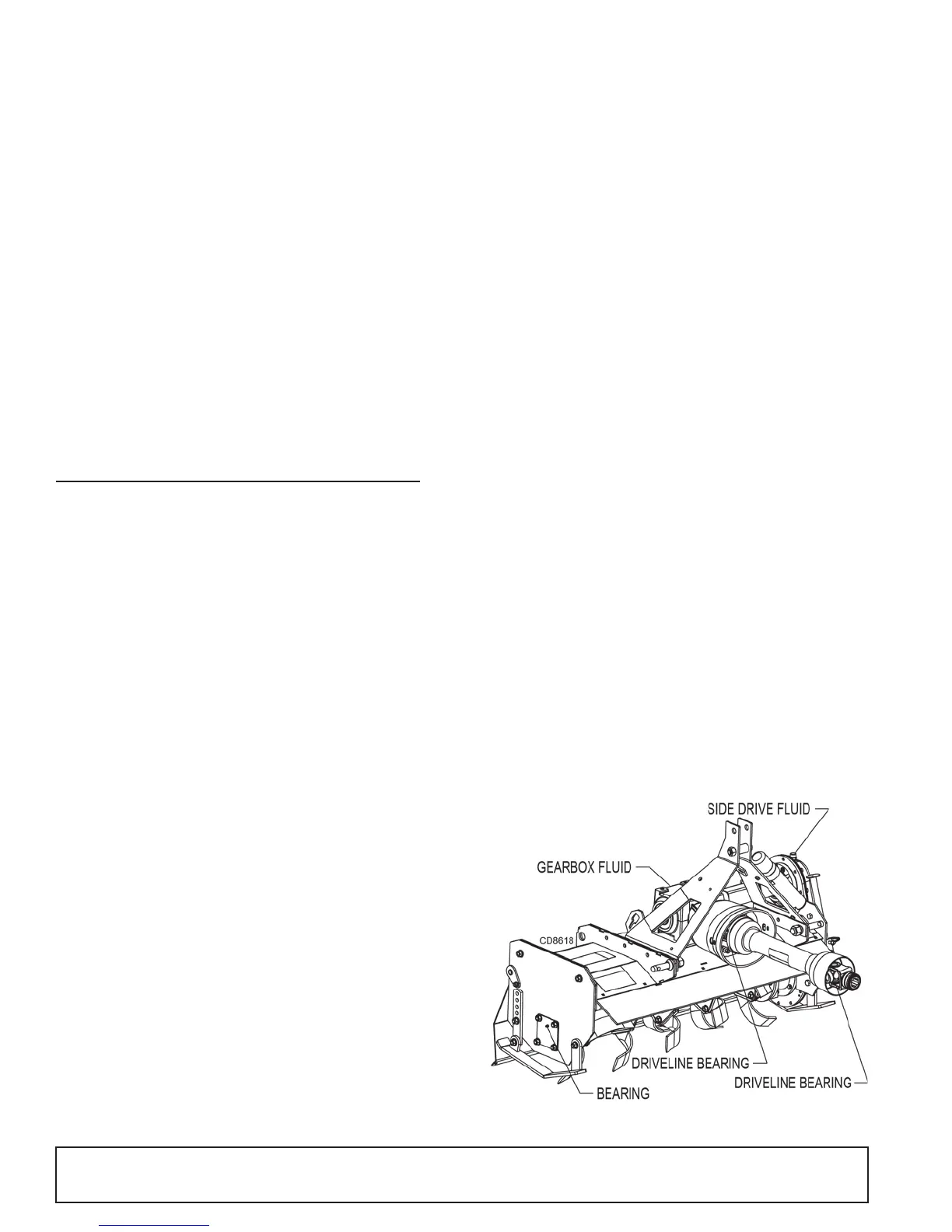

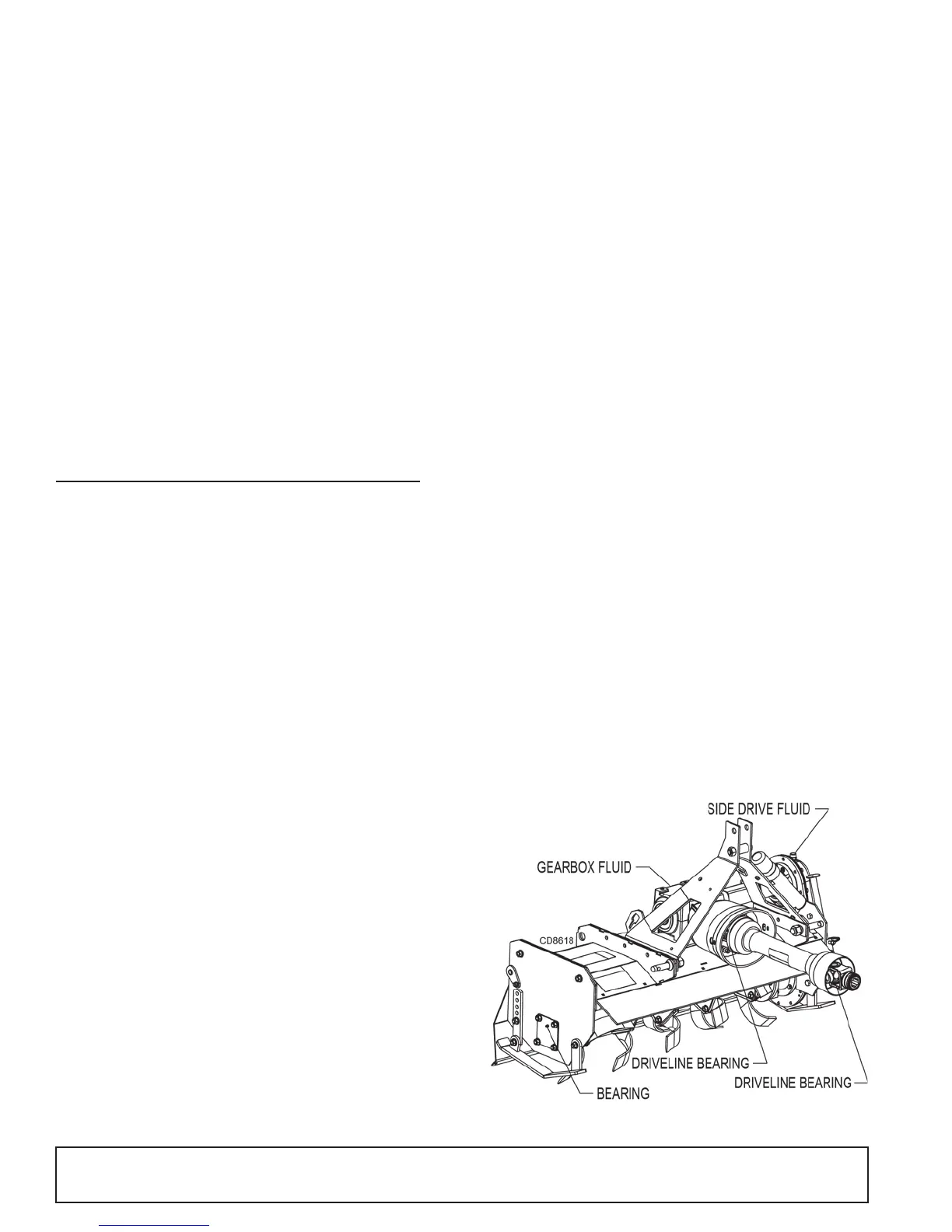

LUBRICATION INFORMATION

1. Do not let excess grease collect on or around

parts, particularly when operating in sandy areas.

2. See Figure 13 for lubrication points and frequency

of lubrication based on normal operating condi-

tions. Severe or unusual conditions may require

more frequent lubrication.

3. Use a lithium grease of #2 consistency with a

MOLY (molybdenum disulfide) additive for all loca-

tions unless otherwise noted. Be sure to clean fit-

tings thoroughly before attaching grease gun. Two

good pumps of most guns is sufficient when the

lubrication schedule is followed.

PTO DRIVE LINES

Periodically check the yokes on front PTO. Make sure

the bolts and nuts are tight and the yoke is not moving

on the shaft. PTO shafts and U-joints should be spar-

ingly lubricated monthly.

QUALIFIED TECHNICIAN MAINTENANCE

GEARBOX LUBRICATION

The gearboxes should be checked quarterly to be sure

that the oil level is maintained at half full. Use plug

located halfway up back face of gearbox to check/fill

oil. A high quality gear oil with a viscosity index of 80W

or 90W and an API service rating of GL-4 or -5 is rec-

ommended for use in the gearboxes. Oil should be

changed after the first 30 hours or 30 days of operat-

ing; then checked regularly for leakage. In the case of

seasonal usage, it is best to change the oil at the end

of the season to remove moisture and corrosive con-

taminants.

Use a 5/16” Allen wrench to remove fill plug.

BEARING LUBRICATION

Lubrication of the bearings will vary considerably with

conditions. As a rule, bearings should be under-lubri-

cated rather than over-lubricated. Over-lubrication can

cause seals to blow out.

NOTICE

■

Replacement bearings should be only high

quality original equipment bearings for longer life.

Install new complete bearing housing if needed or just

replace the bearing insert. The shafts should be

straight, free of burrs, and up to size. If shaft is worn,

replace it prior to completing assembly.

BEARING AND SHAFT SERVICE

1. Place tiller on level, dry surface and block tiller.

(See Blocking Method).

2. Support rotor shaft with blocking or strap so that

bearing assembly does not support weight of rotor.

3. Remove 1/2” flange lock nuts from bearing cover,

gasket and external snap ring from shaft.

4. End plate may be removed from frame to repair or

replace bearing assembly by removing top two 1/2”

flange lock nuts and bolts.

5. Replace inside gasket, bearing assembly, bearing,

internal snap ring, or double lip seal as needed.

6. Install bearing assembly on shaft locking into place

with external snap ring.

7. Install inside gasket and end plate onto bearing

and main frame with top two 1/2” bolts and nuts

and bolts in bearing assembly.

8. Place outside gasket and bearing cover over end-

plate and bolts with 1/2” flange lock nuts tightened

into place.

9. Add grease into bearing cavity so that it is half

filled. (Approximately 40 pumps)

DRIVELINE LUBRICATION

1. Lubricate the driveline slip joint every 8 hours of

operation. Failure to maintain proper lubrication

could result in damage to u-joints, gearbox, and

driveline.

2. Lower tiller to ground, disconnect driveline from

tractor PTO shaft, and slide halves apart. Do not

disconnect the halves from each other.

3. Apply a bead of grease completely around male

half where it meets female half. Slide drive halves

over each other several times to distribute grease.

4. Apply one pump of grease to each driveline u-joint

grease fitting.

5. Apply one pump of grease to each of the plastic

driveline shield bearings.

Figure 13. Lubrication Points

Loading...

Loading...