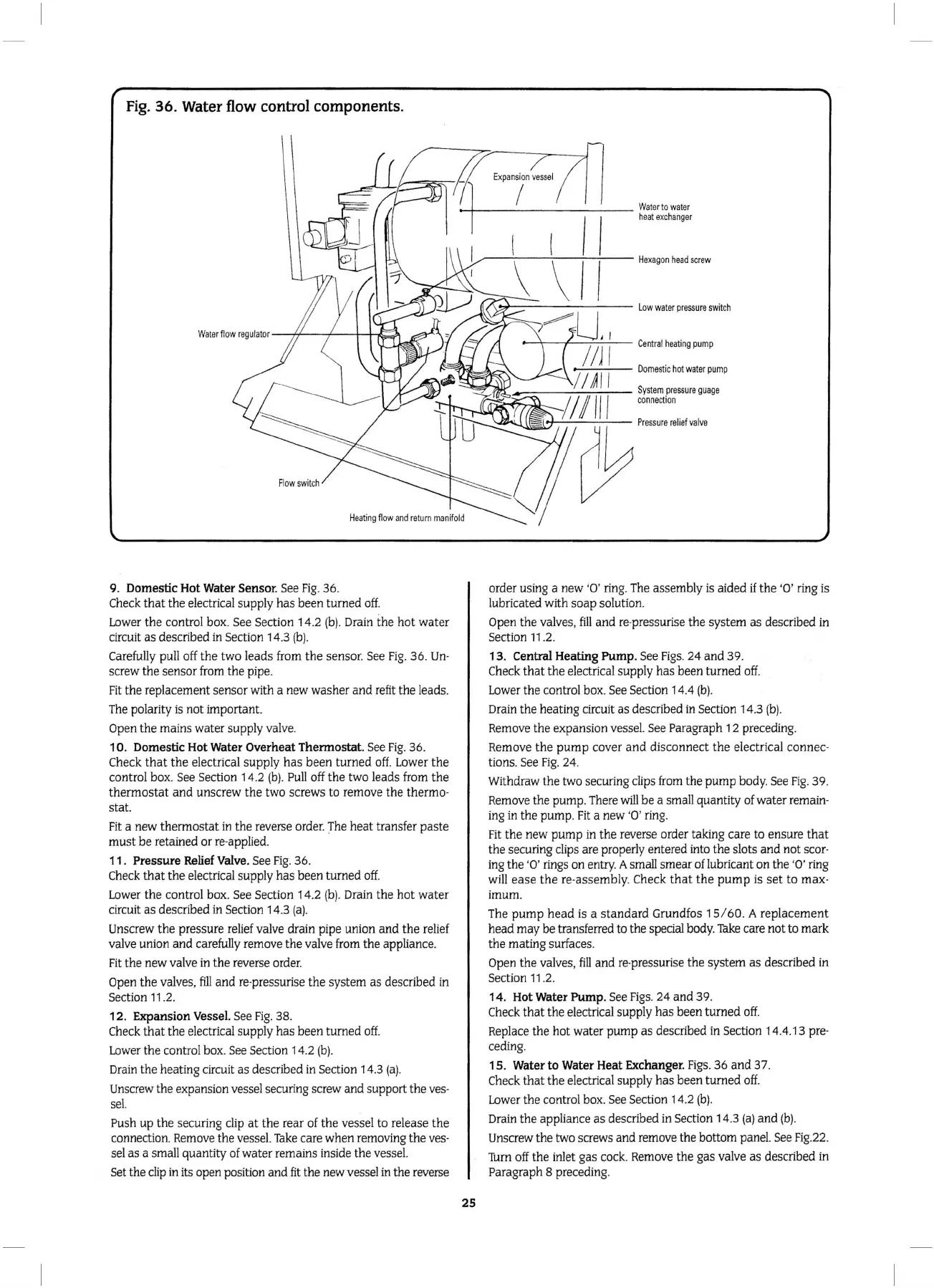

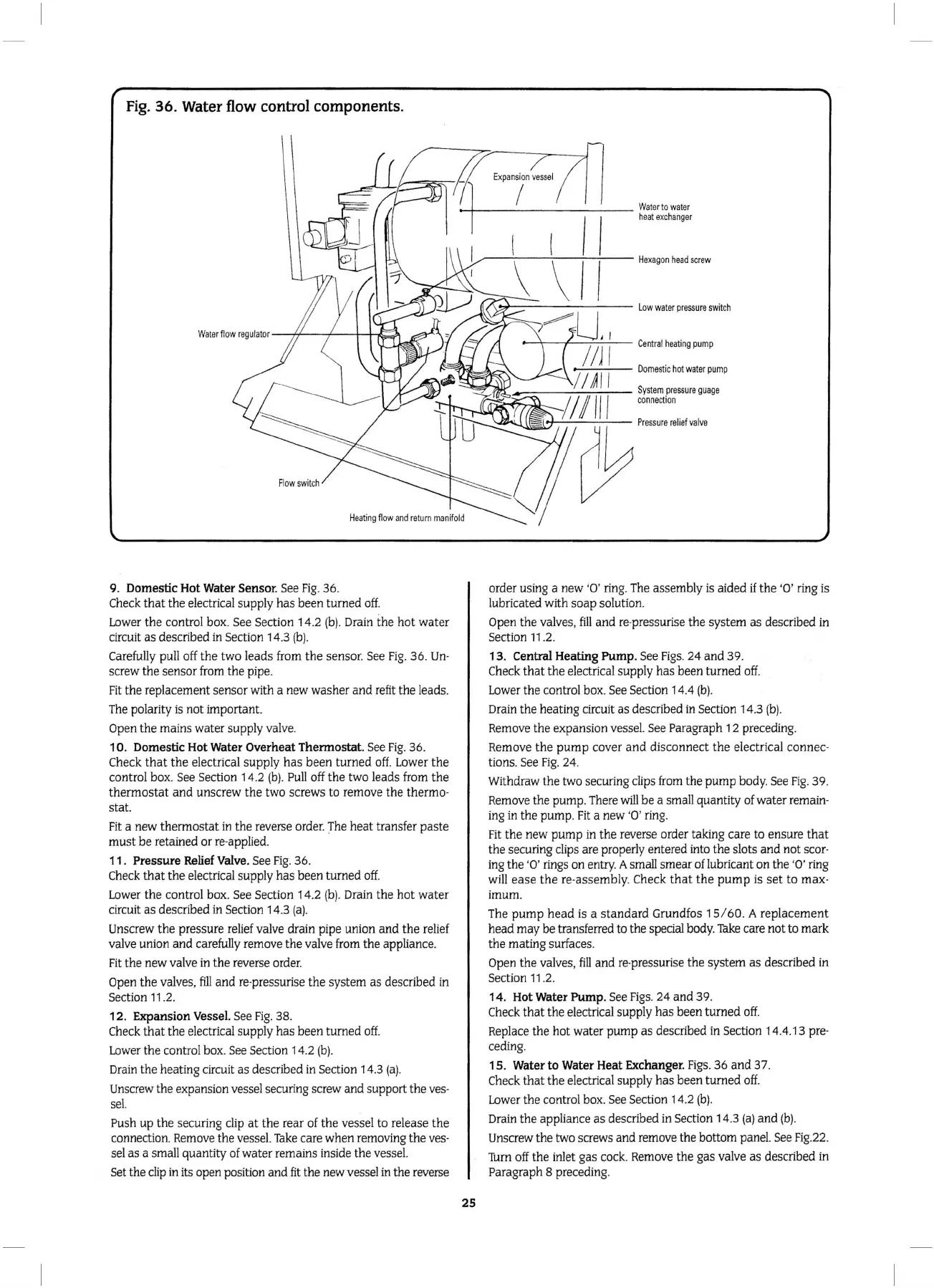

Fig.

36.

Water

flow control components.

Fl

ow

swit

ch

.,r--------

Low

wa

t

er

p

ressure

swit

ch

..-4.

\\

V'

..........-

...,:.....:....,;;....;__

Domes

tic

ho

t

water

pu

mp

.---,------,--:-'-c,....,..,-..,--

System

pre

ssure

guag

e

c

on

nect

io

n

H

eating

flow

a

nd

return

man

i

fo

ld

9. Domestic

Hot

Water Sensor. See

Fig.

36.

Check

that

the

electrical supply

has

been turned off.

Lower

the

control box. See Section 14.2

(b)

. Drain

the

hot

water

circuit as described in Section

14

.3

(b)

.

Carefully pull off

the

two leads from

the

sensor. See

Fig

. 36. Un·

screw

the

sensor from

the

pipe.

Fit

the

replacement sensor with a new washer

and

refit

the

leads.

The polarity is

not

important.

Open

the

mains water supply valve.

10.

Domestic

Hot

Water Overheat Thermostat. See

Fig

. 36.

Check

that

the

electrical supply

has

been turned

off.

Lower

the

control box. See Section 14.2

(b)

. Pull off

the

two leads from

the

thermostat

and

unscrew

the

two screws to remove

the

thermo·

stat.

Fit

a new thermostat in

the

reverse order. The

heat

transfer

paste

must

be

retained or re-applied.

11 . Pressure Relief Valve. See

Fig

.

36

.

Check

that

the

electrical supply

has

been turned

off.

Lower

the

control box. See Section 1 4.2

(b).

Drain

the

hot

water

circuit

as

described in Section 14.3

(a).

Unscrew

the

pressure relief valve drain pipe uni

on

and

the

relief

valve union

and

carefully remove

the

valve from

the

appliance.

Fit

the

new valve

in

the

reverse order.

Open

the

valves,

fill

and

re·pressurise

the

system

as

described in

Section

11

.2.

12.

Expansion Vessel. See

Fig

. 38.

Check

that

the

electrical supply

has

been turned

off.

Lower the control box. See Section 14.2

(b).

Drain the heating circuit

as

described in Section 14.3

(a).

Unscrew the expansion vessel securing screw

and

support

the

ves·

sel.

Push up

the

securing clip

at

the

rear of

the

vessel to release

the

connection. Remove

the

vessel.

Take

care when removing

the

ves·

sel

as

a small quantity of water remains inside the vessel.

Set the

clip

in its open position

and

fit

the new vessel in

the

reverse

25

order using a new

'0'

ring. The assembly is aided

if

the

'0'

ring is

lubricated with

soap

solution.

Open

the

valves,

fill

and

re·pressurise

the

system

as

described in

Section 11.2.

13

. Central Heating Pump. See

Figs.

24

and 39.

Check

that

the

electrical supply has been turned

off.

Lower

the

control box. See Section 14.4

(b).

Drain

the

heating circuit

as

described

in

Section 14.3

(b)

.

Remove

the

expansion vessel. See Paragraph 1 2 preceding.

Remove

the

pump

cover

and

disconnect

the

electrical connec·

tions. See F

ig.

24.

Withdraw

the

two securing clips from

the

pump

body

. See

Fig

.

39

.

Remove the pump. There

will

be

a small quantity of water remain·

ing

in

the

pump.

Fit

a new '0 ' ring.

Fit

the

new

pump

in

the

reverse order taking care to ensure

that

the

securing clips are properly entered into the slots

and

not

scar·

ing the

·o·

rings on entry. A small smear oflubricant

on

the ·

o·

ring

will

ease

the

re-assembly. Check

that

the

pump

is

set

to max·

imum.

The

pump

head

is a

standard

Grundfos 1 S/ 60. A

replacement

head

may

be

transferred to the special

bod

y.

Take

care not to mark

the

mating surfaces.

Open

the

valves,

fill

and

re·pressuri

se

the

system

as

described

in

Section 11.2.

14

.

Hot

Water Pump. See

Figs.

24

and

39

.

Check

that

the

electrical supply has been turned off.

Replace

the

hot water

pump

as

descri

bed

in Section 14.4.

13

pre·

ceding.

15

. Water

to

Water Heat Exchanger.

Figs

.

36

and

37.

Check

that

the

electrical supply

has

been

turned

off.

Lower

the

control box. See Section 14.2

(b)

.

Drain

the

appliance

as

described

in

Section 14.3

(a)

and

(b).

Unscrew

the

two screws and remove the bottom panel. See

Fig

.22.

Turn

off

the

inlet gas cock. Remove

the

gas valve

as

described in

Paragraph 8 preceding.

Loading...

Loading...