Pre-Installation

Greenstar Danesmoor Utility

ErP

and Utility System

ErP

- 6 720 813 286 (2014/09) 19

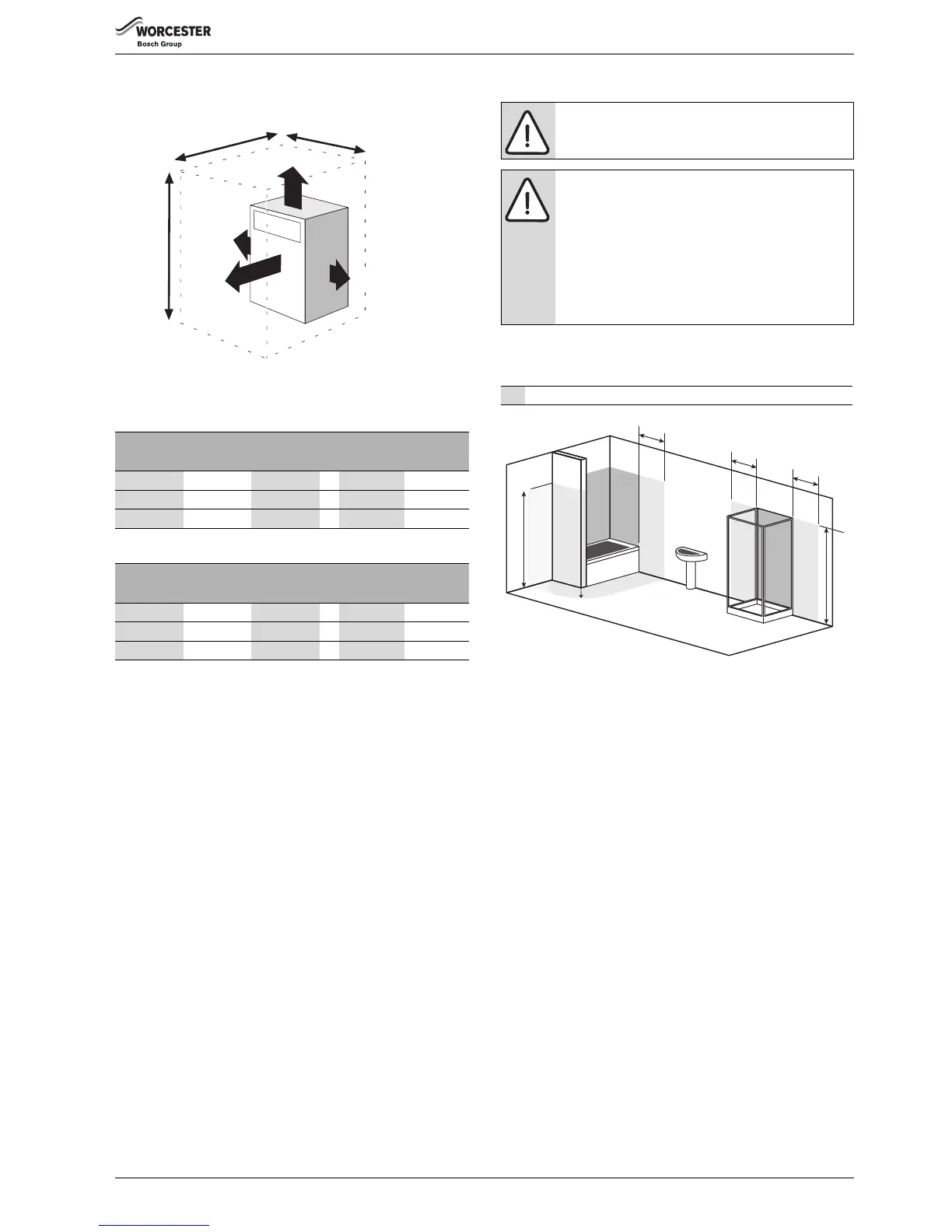

Maintenance clearances

Figure 24 shows the clearances required for maintenance.

Fig. 24 Maintenance and repair clearances

Minimum air vent area (cm

3

) for appliances installed in

compartments

Compartments

Follow the requirements of BS 5410 and note:

• Minimum clearances must be maintained.

• An access door is required to install, service and maintain the boiler

and any ancillary equipment.

• If fitting the boiler into an airing cupboard use a non-combustible

material (if perforated, maximum hole sizes of 13mm) to separate the

boiler from the airing space.

Venting compartments

There must be sufficient clearance around the appliance to allow proper

circulation of ventilation air. The clearances required for installation and

servicing will normally be adequate for ventilation.

• Ventilation must be provided for boilers fitted into compartments as

described in BS 5410.

• Combustion air must not be taken from a room or internal space

containing a bath or shower and must not communicate with a protected

area such as a hall, stairway, landing, corridor, lobby, shaft etc.

• Air vents must allow access for clean free air and must be sited to

comply with the flue terminal position requirements.

• Air ducting runs must not exceed 3m.

• Low level air vents must be less than 450mm from the floor.

• A warning label must be added to the vents with a statement to the

effect: ''Do not block this vent. Do not use for storage.”

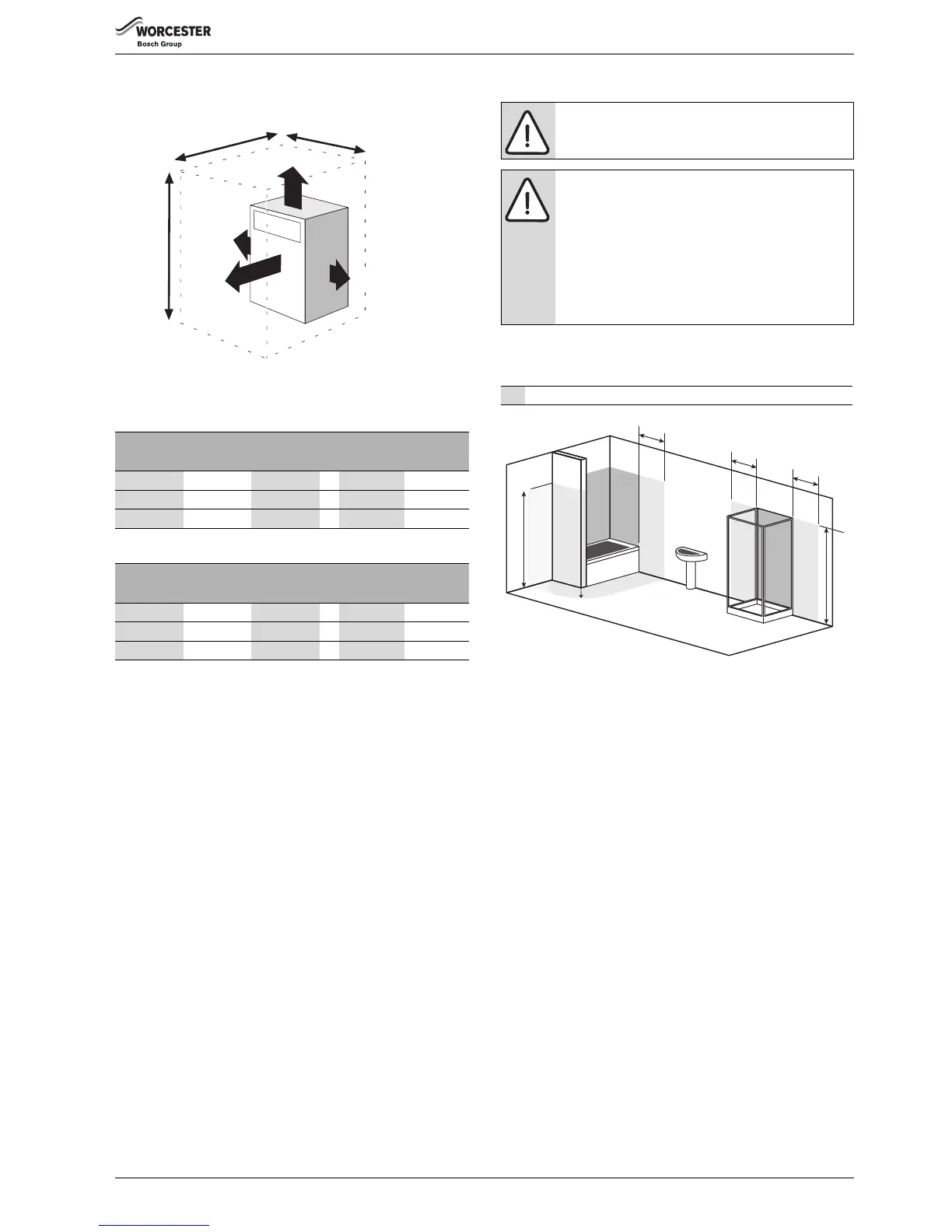

Showers/bathrooms

The boiler must not be installed in the bath or shower or in zones 1 or 2

(the shaded areas shown on the diagrams opposite).

The boiler can be installed outside the shaded areas.

Fig. 25 Bathroom zones

4.8 Flue terminal positions

Flue terminals must be positioned to avoid combustion products

entering into buildings.

The flue must be fitted and terminated in accordance with the

recommendations of BS5410.

The flue must not cause an obstruction.

Discharge from the flue outlet must not be a nuisance.

Flue gases have a tendency to plume and in certain weather conditions a

white plume of condensation will be discharged from the flue outlet

which could be regarded as a nuisance, for example, near security

lighting.

There should be no restriction preventing the clearance of combustion

products from the terminal.

The air inlet/outlet duct and the terminal of the boiler must not be closer

than 25mm to any combustible material. Detailed recommendations on

protection of combustible materials are given in BS 5410:1

A protective stainless steel terminal guard, must be fitted if the terminal

is 2m or less above a surface where people have access.

See 'Contact Information' on the back cover for flue guard information.

The following additional guidelines (from part L Exceptions Guidance

Document) are recommended when determining the flue outlet

position:

Avoid discharging flue gases into car ports or narrow passageways.

Model

Internal ventilation External ventilation

High level Low level High level Low level

12/18 198 297 99 198

18/25 275 413 138 275

25/32 330 495 165 330

Table 5 Conventional flue

Model

Internal ventilation External ventilation

High level Low level High level Low level

12/18 198 198 99 99

18/25 275 275 138 138

25/32 330 330 165 165

Table 6 Room sealed flue

Loading...

Loading...