Commissioning

Greenstar i System

ErP

- 6 720 806 945 (2015/07)

39

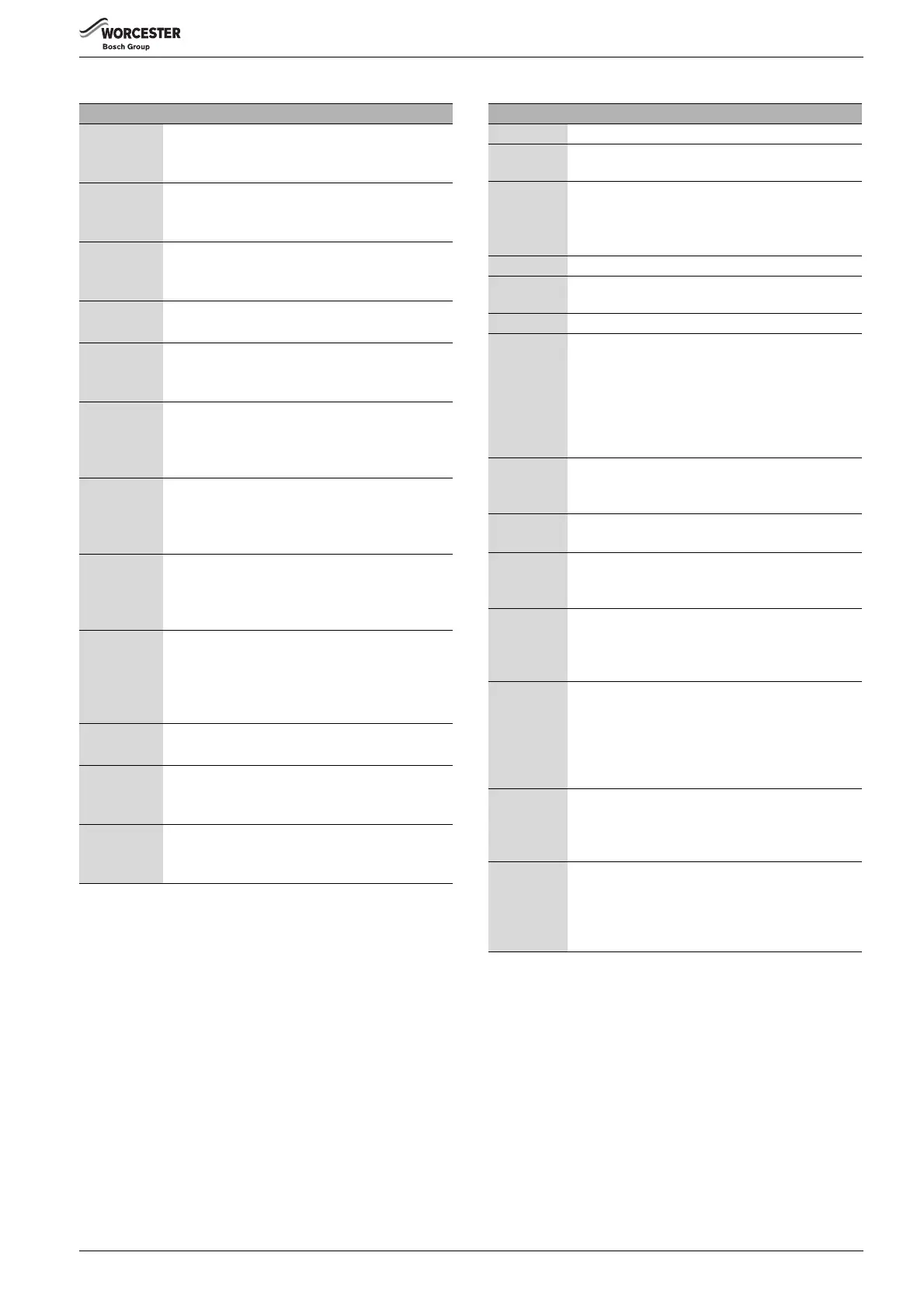

Info menu listing Operational status codes listing

Info menu No. Description

i1 Current status

• Appliance current operating status (see table 33

for operational status codes).

i2 Previous status

•Appliance previous operational status (see

table 33 for operational status codes).

i4 Maximum DHW output

• Maximum DHW cylinder output (kW) set on the

appliance (set in menu 2.1b).

i8 Ionization current

• Measured ionisation current (μA).

i9 Flow temperature

• Measured primary flow temperature of the

appliance ( °C).

i11 DHW outlet temperature

• Measured DHW temperature of the cylinder ( °C),

(only available when using the optional integral

diverter valve kit).

i12 DHW cylinder temperature setpoint

• Displays the required temperature for the DHW

cylinder as set control panel ( °C), (only available

when using the optional integral diverter valve kit).

i13 DHW cylinder temperature

• Measured DHW cylinder sensor temperature

( °C),(only available when using the optional

integral diverter valve kit).

i15 Outdoor sensor

• Temperature reading from outdoor temperature

sensor ( °C), (only available if an outdoor sensor

accessory is fitted when using the optional integral

diverter valve kit).

i20 CU version

• Software version of the control box

i21 HMI version

• Software version of the HIS (Human Interface

Software).

i22 HCM version

• Identification number of the HCM (Heating Control

Module) and release version.

Table 32 Info menu

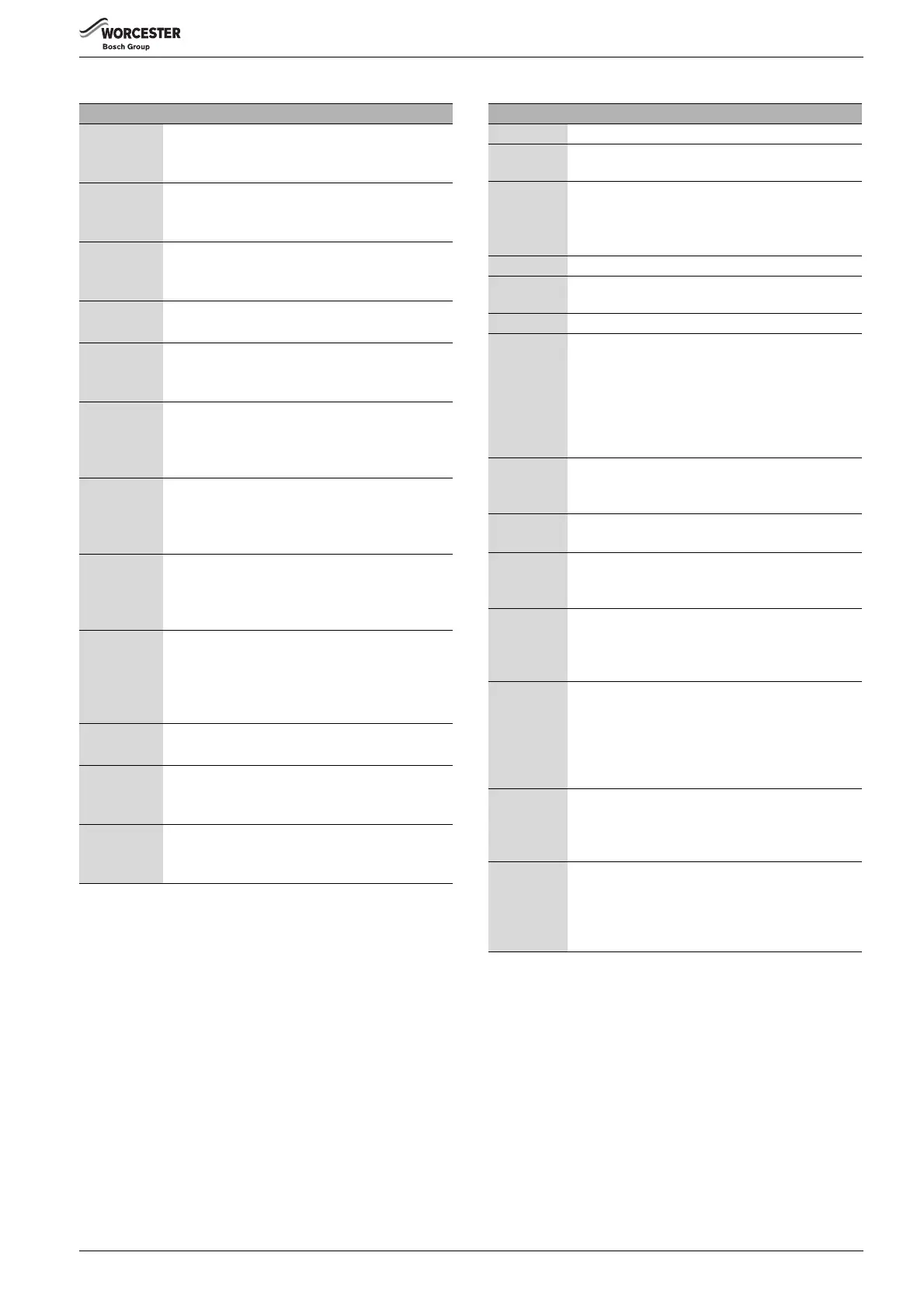

Status code Description

200 CH system is being heated.

201 DHW cylinder system is being heated (only available

when using the optional integral diverter valve kit).

202 Anti rapid cycle mode.

• The boiler has commenced anti-cycle period for CH.

Can be adjusted in boiler settings (2.3b).

• Default 5 Minutes

203 System stand by

204 System waiting, primary flow temperature above set

temperature point

208 Appliance in service Test mode (Min/Max)

265 EMS intelligent controller has forced stand-by-mode

due to low heating load.

• The appliance is compensating for the power

required from the EMS room controller and is less

than the minimum output of the boiler (only

available when using EMS intelligent controls with

the optional integral diverter valve kit).

268 Component test mode.

• Appliance is running the manual component test as

activated in the menus.

270 Power up mode.

• Appliance is initialising.

283 Burner starting.

• The boiler prepares for a burner start. The fan and

the pump are being controlled.

284 Gas valve(s) opened, flame must be detected within

safety time.

• The boiler prepares for a burner start. The gas valve

is being controlled.

305 Anti fast cycle mode (Domestic Hot Water keep warm

function.

• Diverter valve is held in hot water position for a

period of time (determined by the software) after

hot water demand (only available when using the

optional integral diverter valve kit).

357 Appliance in air purge mode.

• Primary Heat Exchanger air venting program active -

approximately 100 seconds (only available when

using the optional integral diverter valve kit).

358 Three way valve kick.

• If the 3-way valve hasn't moved in up to 48 hours,

the valve will operate once to prevent seizure, (only

available when using the optional integral diverter

valve kit).

Table 33 Operational status codes

Loading...

Loading...