22

OPERATING INSTRUCTIONS

NOTE: Before using the tool, read the

instruction book carefully.

INTENDED USE

The machine is intended for hammer drilling

in concrete, brick and stone. It is also suitable

for drilling without impact in wood, metal,

ceramic and plastic. Machines with electronic

control and right/left rotation are also suitable

for screwdriving.

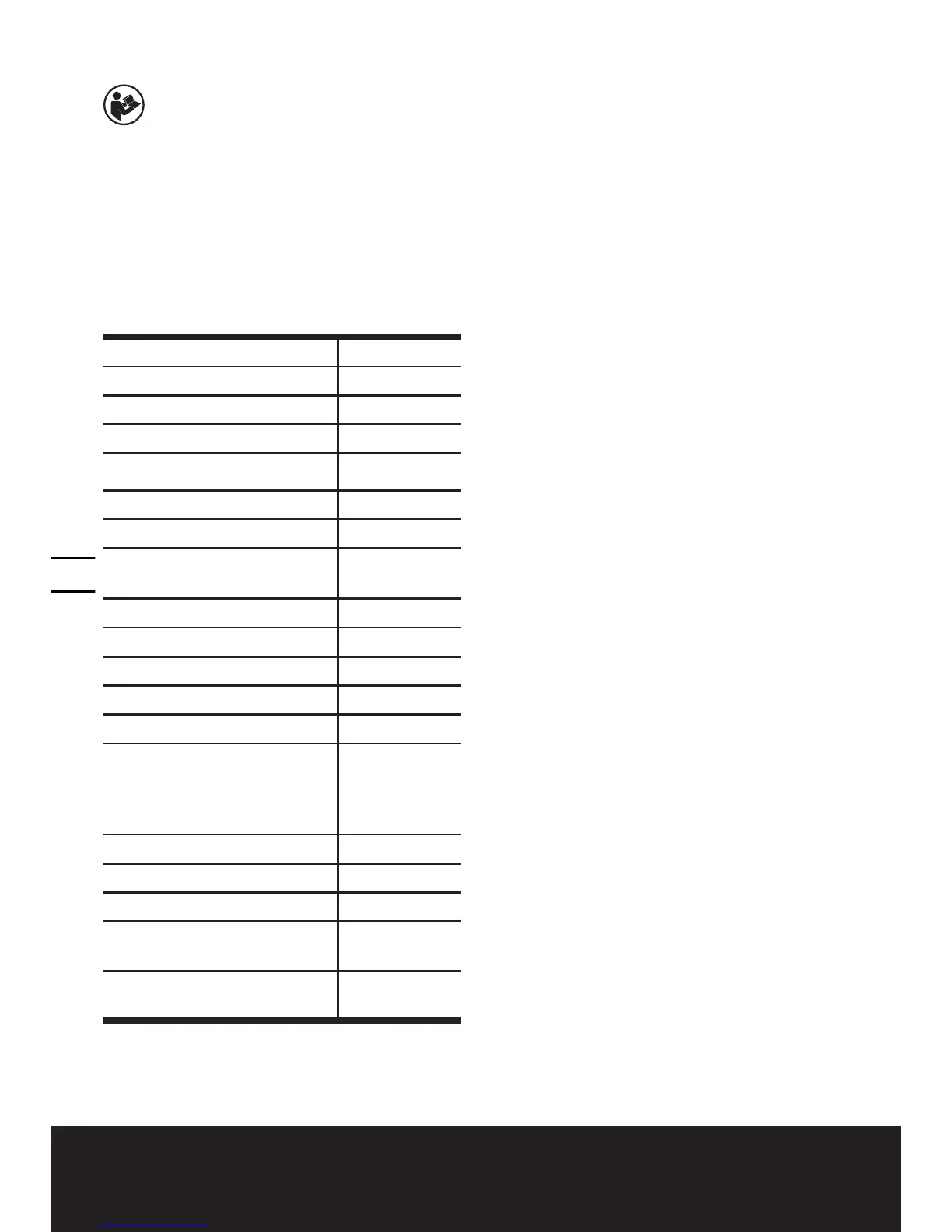

OPERATION

ACTION FIGURE

Removing

The Battery

See Fig. A1

Inserting The Battery See Fig. A2

Selecting The Operating Mode See Fig. B

HAMMER DRILLING

Inserting Drill Bits See Fig. C1

Removing Drill Bits See Fig. C2

DRILLING &

SCREWDRIVING

Inserting Adaptors See Fig. D1

Inserting Bits into Chuck See Fig. D2

Removing Adaptors See Fig. D3

Removing Bits from Chuck See Fig. D4

On/Off Switch See Fig. E

Switch Lock

NOTE: The Switch Trigger

Can Be Locked In The Off

Position.

See Fig. F

Forward Rotation Control See Fig. G

Reverse Rotation Control See Fig. H

LED Light See Fig. I

Temperature Dependent

Overload Protection

/

Protection Against Deep

Discharging

/

WORKING HINTS FOR YOUR

TOOL

If your power tool becomes over heated, set

the speed to maximum and run no load for 2-3

minutes to cool the motor. SDS-plus tungsten

carbide drill bits should always be used for

concrete and masonry.

When drilling in metal, only use HSS drill bits

in good condition. Where possible use a pilot

hole before drilling a large diameter hole.

PROBLEM SOLUTION

1. REASONS FOR DIFFERENT BATTERY

PACK WORKING TIMES

Charging time problems, having not used a

battery pack for a prolonged time will reduce

the battery pack working time. This can be

corrected after several charge and discharge

operations by charging & working with your

tool. Heavy working conditions such as large

screws into hard wood will use up the battery

pack energy faster than lighter working

conditions. Do not re-charge your battery pack

below 0

o

C and above 30

o

C as this will affect

performance.

MAINTENANCE

Remove the battery pack from the tool

before carrying out any adjustment,

servicing or maintenance.

Your power tool requires no additional

lubrication or maintenance, except for the

cleaning & lubrication of the SDS bits and

adaptors before inserting into the chuck.

There are no user serviceable parts in your

power tool. Never use water or chemical

cleaners to clean your power tool. Wipe clean

with a dry cloth. Always store your power tool

in a dry place. Keep the motor ventilation slots

clean. Keep all working controls free of dust.

Occasionally you may see sparks through the

ventilation slots. This is normal and will not

damage your power tool.

Loading...

Loading...