ENGINE

L4100, WSM

1-S52

(EU)

(4) Crankshaft

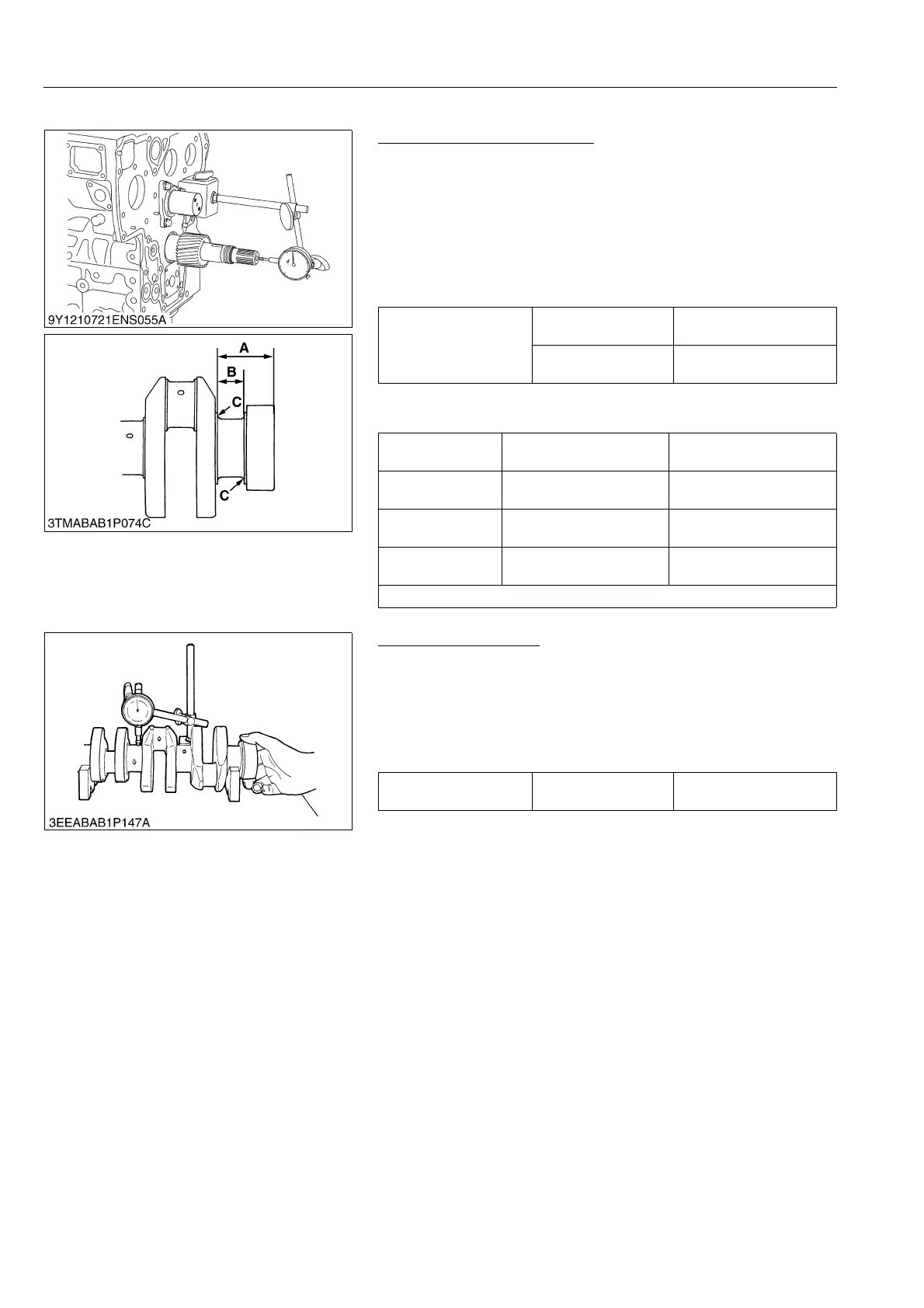

Side Clearance of Crankshaft

1. Set a dial indicator with its tip on the end of the crankshaft.

2. Measure the side clearance by moving the crankshaft to the

front and rear.

3. If the measurement exceeds the allowable limit, replace the

thrust bearings.

4. If the same size bearing is useless because of the crankshaft

journal wear, replace it with an oversize one referring to the

table and figure.

(Reference)

• Oversize dimensions of crankshaft journal

9Y1210278ENS0113US0

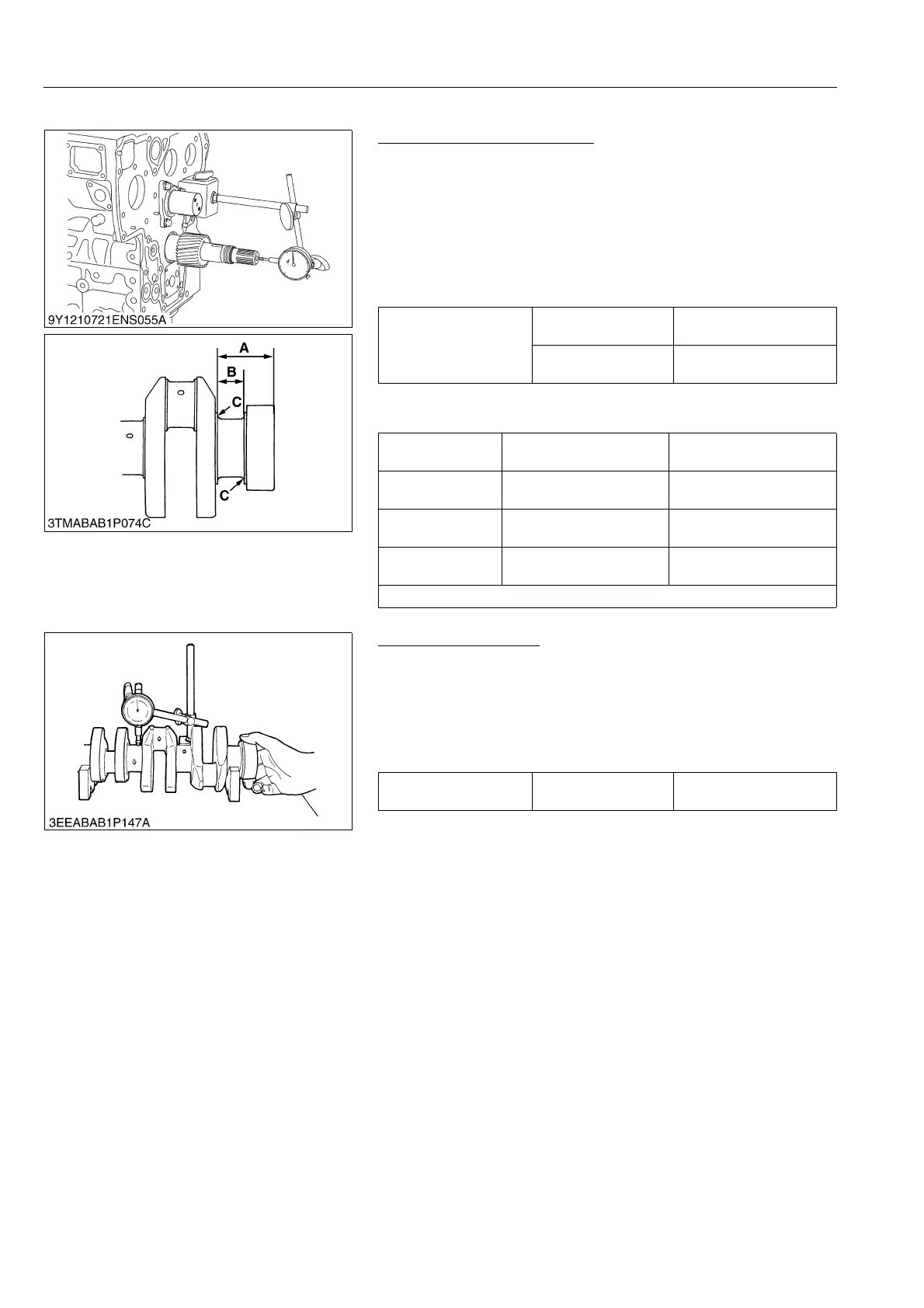

Crankshaft Alignment

1. Support the crankshaft with V blocks on the surface plate at

both end journals.

2. Set a dial indicator with its tip on the intermediate journal.

3. Measure the crankshaft alignment.

4. If the measurement exceeds the allowable limit, replace the

crankshaft.

9Y1210278ENS0085US0

Crankshaft side

clearance

Factory specification

0.15 to 0.31 mm

0.0059 to 0.012 in.

Allowable limit

0.5 mm

0.02 in.

Oversize

0.2 mm

0.008 in.

0.4 mm

0.02 in.

Crankshaft

dimension A

54.50 to 54.70 mm

2.146 to 2.153 in.

54.60 to 54.80 mm

2.150 to 2.157 in.

Crankshaft

dimension B

26.20 to 26.25 mm

1.032 to 1.033 in.

26.40 to 26.45 mm

1.040 to 1.041 in.

Crankshaft

dimension C

2.8 to 3.2 mm radius

0.11 to 0.12 in. radius

2.8 to 3.2 mm radius

0.11 to 0.12 in. radius

The crankshaft journal must be fine-finished to higher than Rmax = 0.4S

Crankshaft alignment Allowable limit

0.02 mm

0.0008 in.

Loading...

Loading...