42

902310

SH M3x10

902316

SH M3x16

7. FINAL ASSEMBLY

NOTE

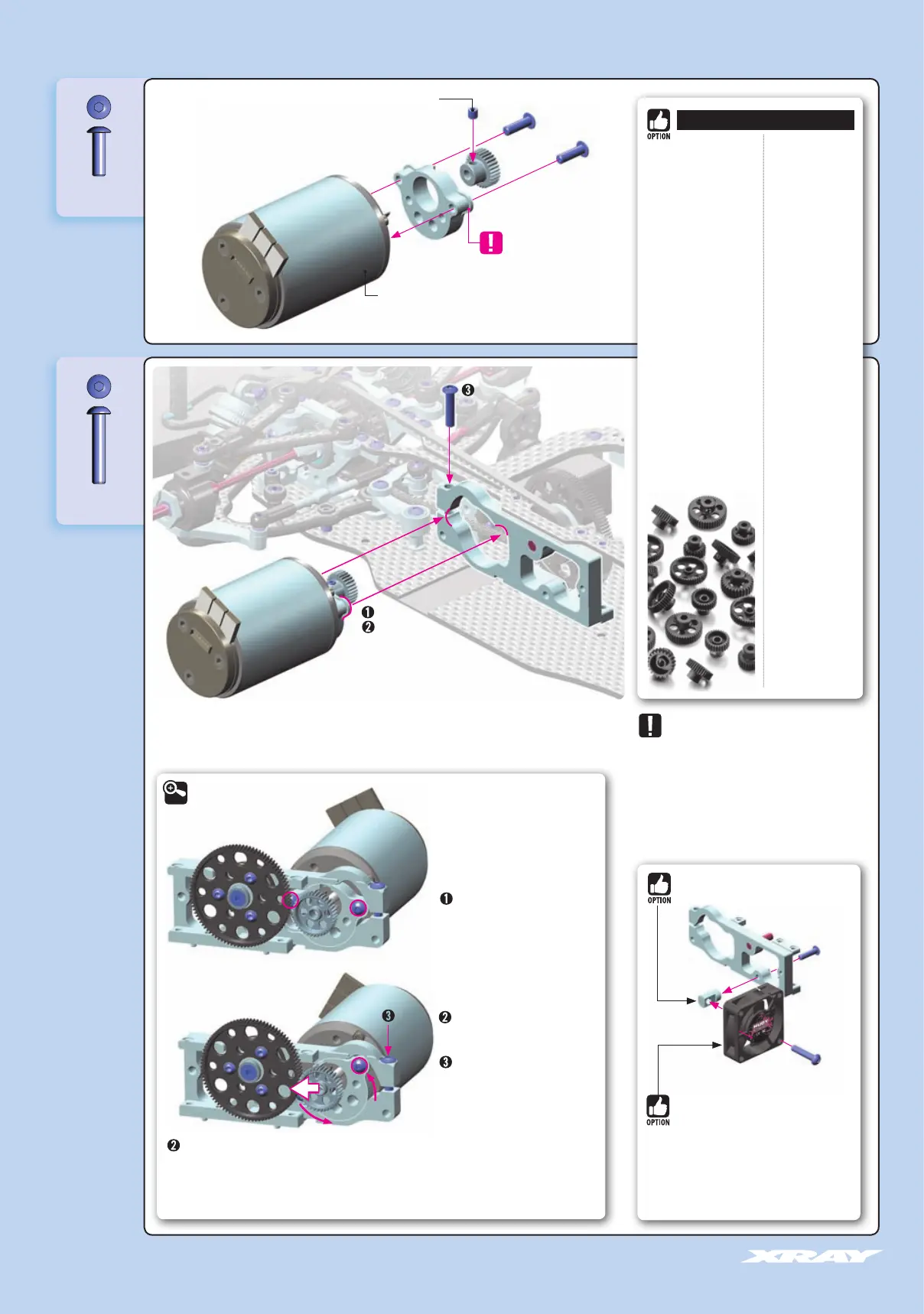

The most-used FWD ratios are 4.5 and 5. Use these

recommended spur gears and pinions to achieve the

desired ratio.

4.5 ratio - 90T spur / 38T pinion

5 ratio - 100T spur / 38T pinion

#305912 12T / 48P

#305913 13T / 48P

#305914 14T / 48P

#305915 15T / 48P

#305916 16T / 48P

#294017 17T / 48P

#305918 18T / 48P

#305919 19T / 48P

#305920 20T / 48P

#294021 21T / 48P

#294022 22T / 48P

#294023 23T / 48P

#305924 24T / 48P

#305925 25T / 48P

#305926 26T / 48P

#305927 27T / 48P

#305928 28T / 48P

#305929 29T / 48P

#294030 30T / 48P

#305931 31T / 48P

#305932 32T / 48P

#294033 33T / 48P

#305934 34T / 48P

#294035 35T / 48P

#305968 18T / 64P

#305969 19T / 64P

#305970 20T / 64P

#305971 21T / 64P

#305972 22T / 64P

#305973 23T / 64P

#305974 24T / 64P

#305975 25T / 64P

#305976 26T / 64P

#305977 27T / 64P

#294128 28T / 64P

#294129 29T / 64P

#294130 30T / 64P

#294131 31T / 64P

#305982 32T / 64P

#294133 33T / 64P

#305984 34T / 64P

#305985 35T / 64P

#294136 36T / 64P

#294137 37T / 64P

#294138 38T / 64P

#294139 39T / 64P

#294140 40T / 64P

#294141 41T / 64P

#294142 42T / 64P

#294143 43T / 64P

#294144 44T / 64P

#294145 45T / 64P

#294146 46T / 64P

#294147 47T / 64P

#294148 48T / 64P

#294149 49T / 64P

#294150 50T / 64P

#294152 52T / 64P

#294154 54T / 64P

#294156 56T / 64P

#294158 58T / 64P

#294160 60T / 64P

ALU PINION GEARS (OPTION)

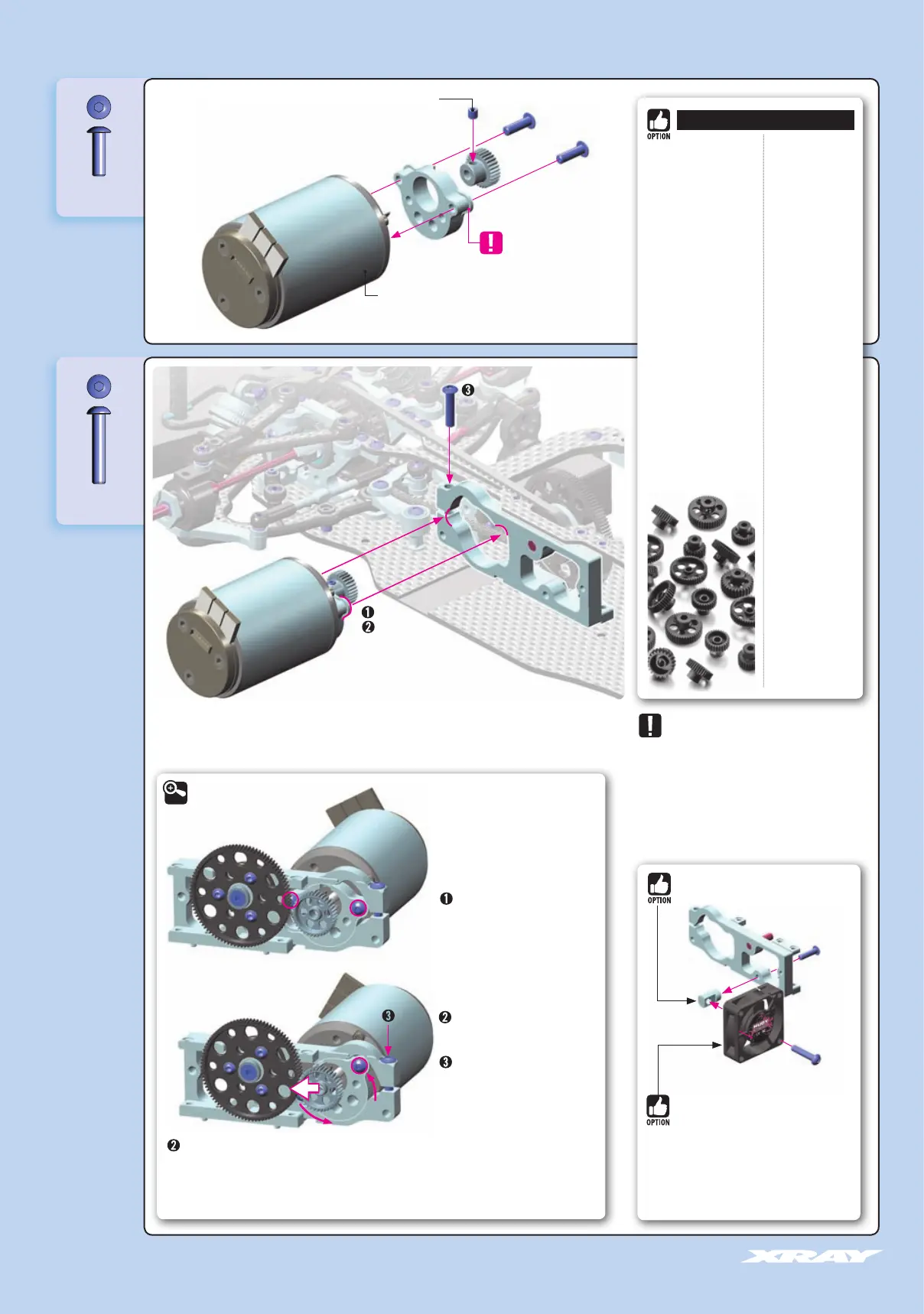

Motor

(NOT INCLUDED)

Pinion & screw

(NOT INCLUDED)

NOTE

ORIENTATION

#306410

ALU FAN MOUNT

#293110 HUDY BRUSHLESS RC FAN 30MM

WITH EXTERNAL SOLDERING TABS

#293111 HUDY BRUSHLESS RC FAN 40MM

WITH EXTERNAL SOLDERING TABS

#293112 HUDY BRUSHLESS RC FAN 30MM

WITH INTERNAL SOLDERING TABS

#293113 HUDY BRUSHLESS RC FAN 40MM

WITH INTERNAL SOLDERING TABS

Adjust the motor so the pinion meshes with the spur gear properly.

Make sure the gear mesh is not too tight.

There should be a small amount of play between the teeth of the

pinion gear and the spur gear.

Attach the motor to the eccentric motor

holder in the indicated orientation.

Tighten the mounting screws.

Adjust the gear mesh by rotating

the eccentric motor holder.

Tighten the clamp screw.

➋

DETAIL

Loading...

Loading...