5

The failed pump will then be locked out and the standby pump will run and take the place of the duty pump.

If a pump trips for any reason it will be locked out and the standby pump will operate in its place.

Once the reason for pump failure has been ascertained and rectified the mode button can be pressed and

OFF can be selected, press mode button again and select Auto and the failed pump will be reset and the unit will

operate normally.

Alternatively the mains switch can be switched off and back on again which will reset the circuit but this will also

open the boiler interlock contacts which may not be desirable.

When parallel operation is selected then when the pressure fails to the set points both pumps will be started and

when pressure rises both pumps will stop, if one pump fails it will be locked out and the remaining pump will operate

on its own.

Maintenance

Routine check (3 monthly intervals)

1. Check that the pump seal is not leaking.

2. Check the pump is not seized and develops the correct pressure.

3. Check that the pump operates without undue noise or vibration.

Routine check (6 monthly intervals)

1. Check the break tank is clean and that the correct water level has been maintained.

2. Check that all screws are tight on electrical components.

3. Check that the earth connections are tight and making good contact.

4. Check that the gas pre charge in the system vessel is at the correct pressure, this should be done by

isolating the vessel from the pressurised line and removing the pressure on the wet side of the vessel.

Once the vessel pressure has been discharged, a tyre gauge can be connected to the pre-charge valve to display

the vessel pre-charge pressure. Recharge as necessary with Nitrogen or dry air.

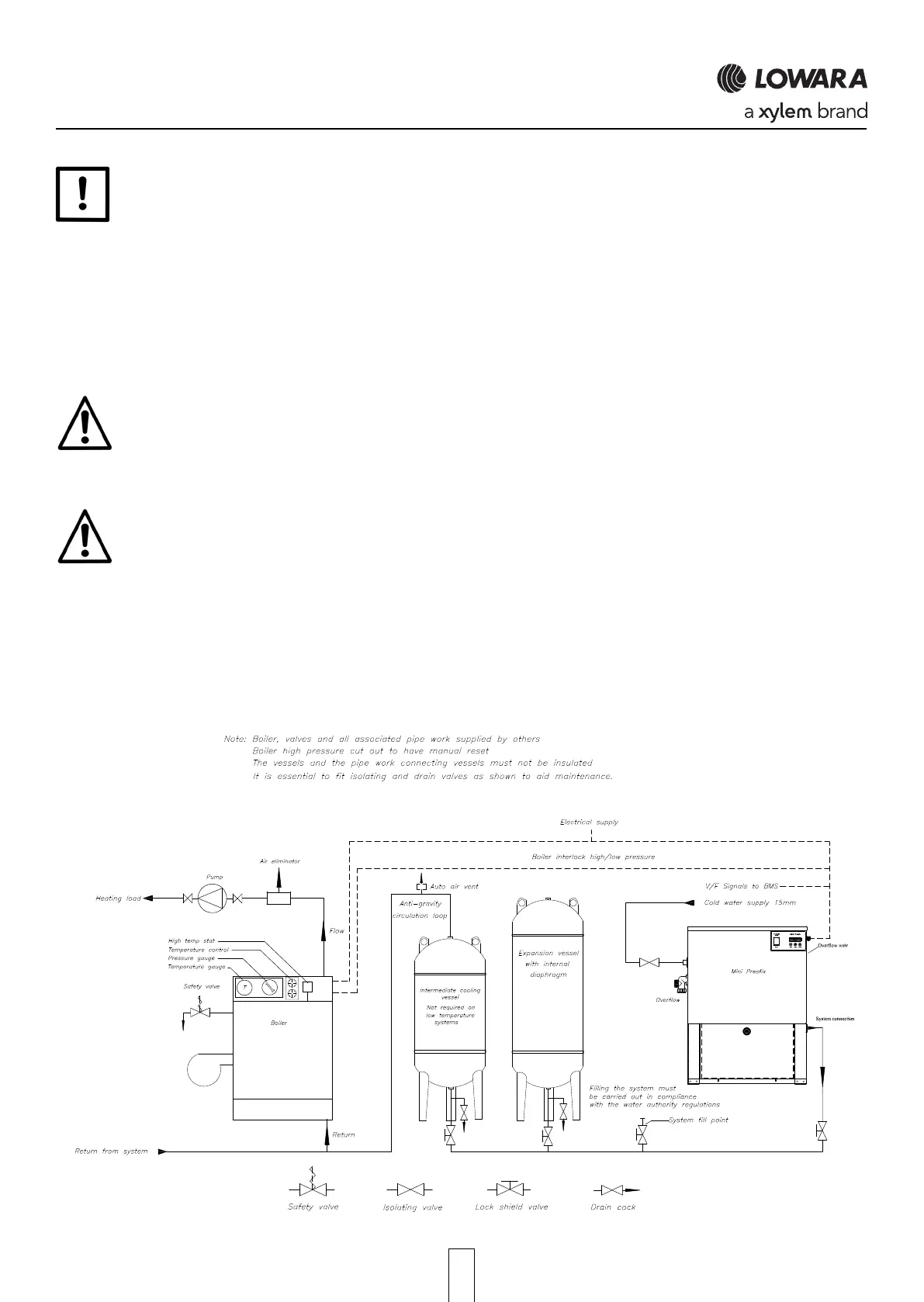

Typical MTHW sealed system max. 120°C.

Intermediate vessel only required on systems withy return temperatures higher than 70°C

Figure 1.

O&M Micro Presfix_Layout 1 29/03/2017 11:15 Page 5

Loading...

Loading...