7. If an oxide film forms on the tip, it can be removed by careful buffing with a

600-800 grit emery cloth, isopropyl alcohol or equivalent and then wrapping rosin

core solder around the newly exposed surfaces. Coat the tinned areas with

rosin-core solder after the resin-core has melted.

NEW TIPS

Applying the following steps will lead to optimum life. .

1. Set temperature to min. then turn the main power switch to the" ON" position.

2. Set temperature to 250'C (482'F).

3. Coat the tinned surfaces with rosin-core solder after reaching 250'C (482'F).

4. Set to desired temperature after allowing the unit to idle at 250'C for 3 minutes.

5. The iron will be ready for use once it reaches the preset temperature.

IMPORTANT: Remove and clean the tip daily. If a new tip is installed, remove any

loose build up in the barrel assembly, otherwise the tip may fuse to the heating

element or retaining barrel.

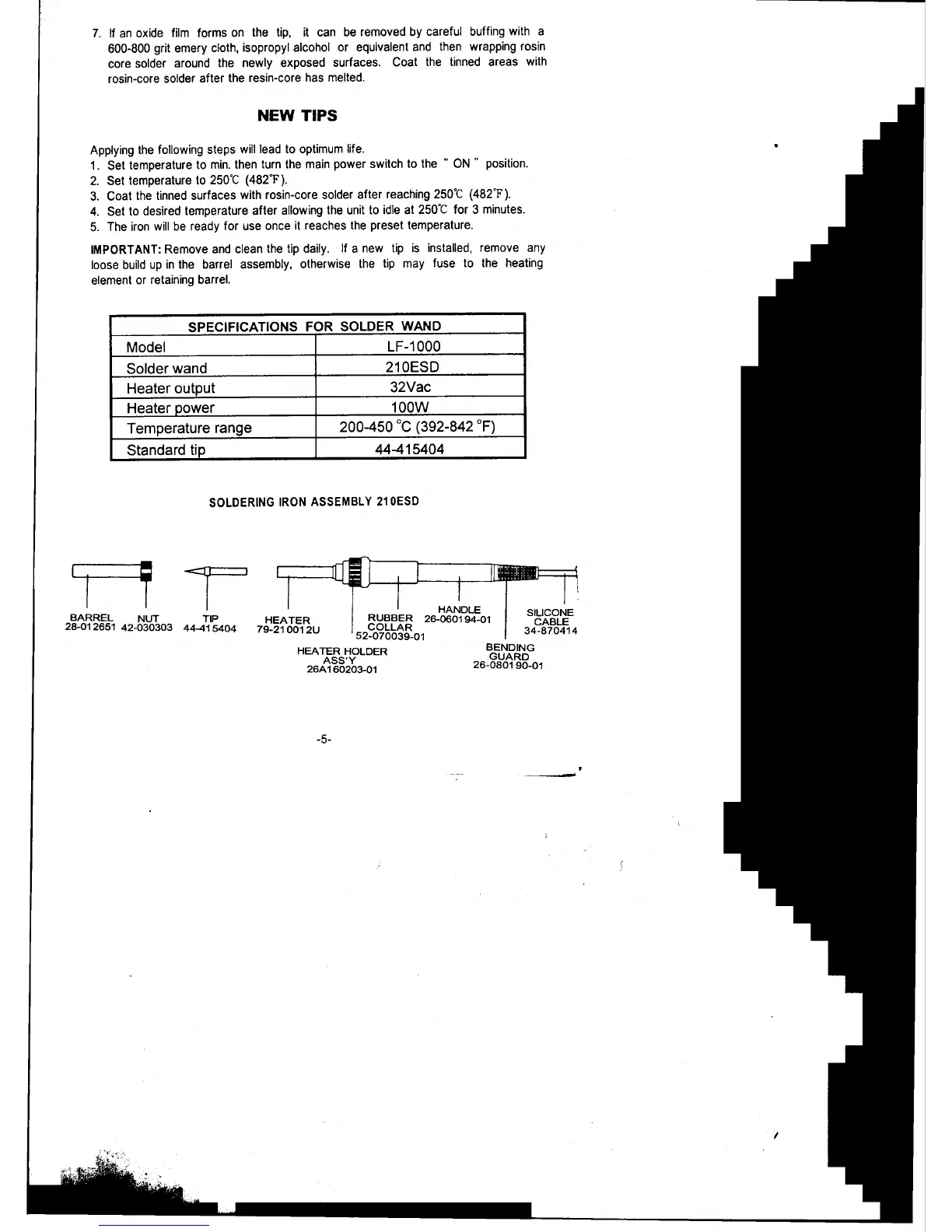

SPECIFICATIONS FOR SOLDER WAND

Model LF-1000

Solder wand 210ESD

Heater output 32Vac

Heater ower 100W

Temperature range 200-450 °C (392-842 OF)

Standard tip 44-415404

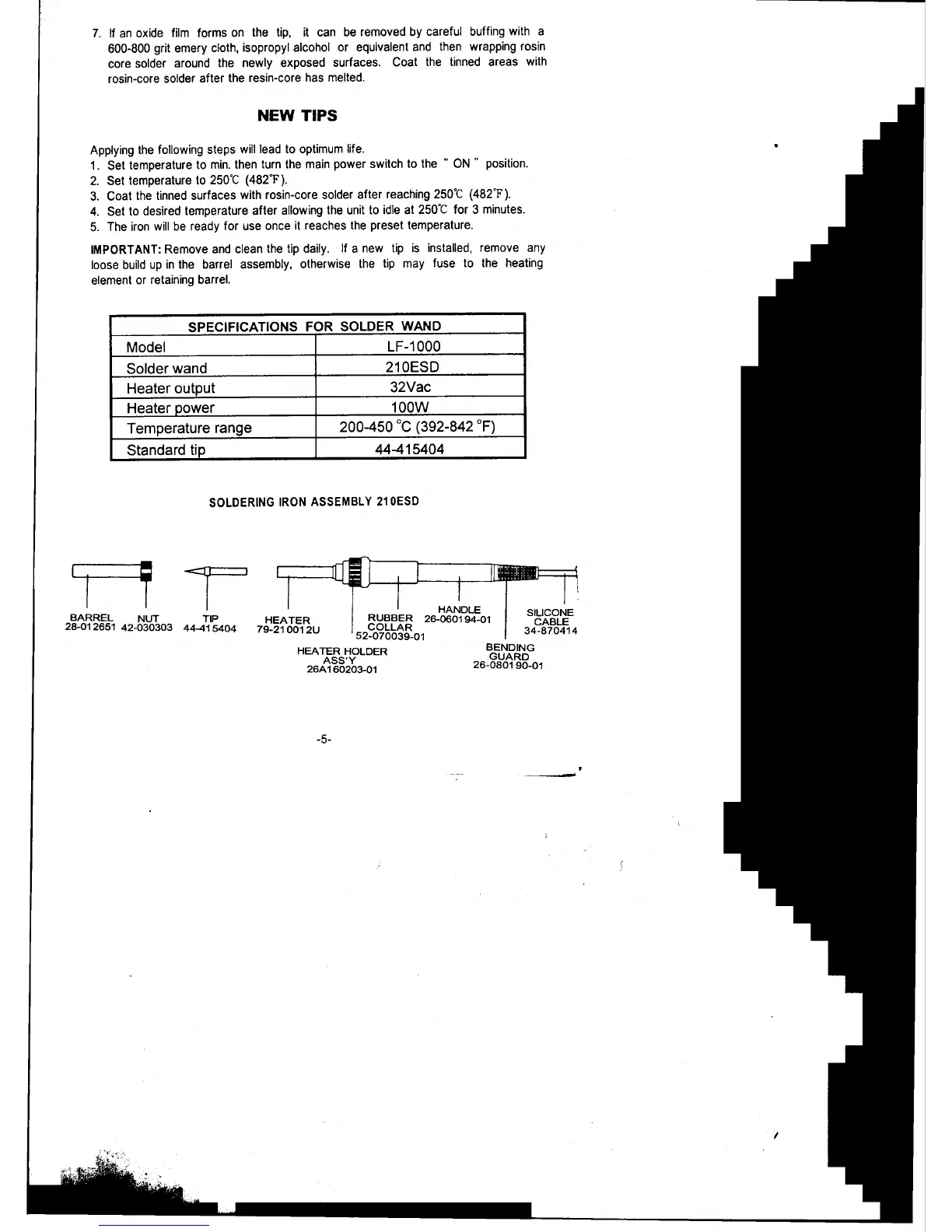

SOLDERING IRON ASSEMBLY 21 OESD

ft THEA TER RUBBER 26-'6ii~~~:01 SILICONE

28-012651 42-030303 44-415404 79-210012U COLLAR CABLE

52-070039-01 34-870414

HEATER HOLDER BENDING

ASS'Y GUARD

26A160203-01 26-080190-01

-5-

,

-~

)

i S

I

Loading...

Loading...