MAINTENANCE

TIP MAINTENANCE AND DRESSING

Tips can be changed or replaced simply by unscrewing the knurled nut barrel

assembly. The station must be switched off and allowed to cool before this operation

as damage may result if the system is left on without the tip in place!

After removing the tip, blowout any oxide dust that may have formed in the tip

retaining area of the barrel. Be careful to avoid getting this dust in your eyes. Replace

the tip and screw back the knurled nut barrel assembly using only firm hand pressure .

to tighten. Pliers should only be used to tighten the nut to avoid burning your fingers,

but care should be taken not to over-tighten as this could damage the element.

GENERAL CLEANING

The outer cover of the iron and station may be cleaned with a damp cloth using small

amounts of liquid detergent. Never submerse the unit in liquid or allow any liquid to

enter the case of the station. Never use any solvent to clean the case.

SERVICE

If the iron or station should become faulty or, for some reason not operate normally,

the system should be returned to the service department of your authorized dealer or

service agent or similarly qualified person in order insure proper repairs and to avoid

any hazards from developing.

WARNING: This iron must be returned to its stand when not in use.

WARNING: Keep out of the reach of children.

WARNING: Do not inhale solder fumes.

WARNING: Keep tip and heating element away from the body, clothes and

flammable material when in operation.

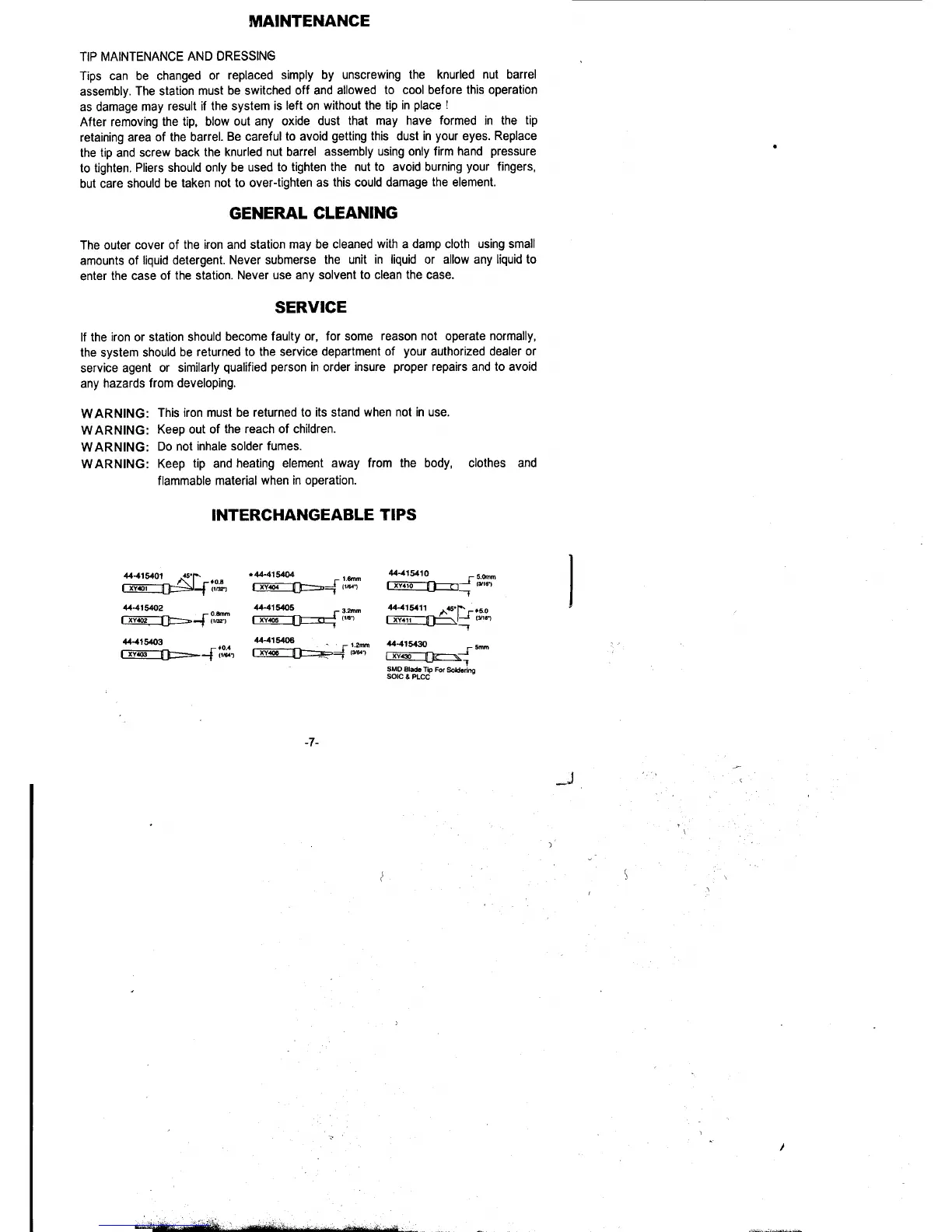

INTERCHANGEABLE TIPS

~~~-415401'" *44-415404 em 44-415410 SOmm

I+08 1 m J

XV401 -f(I';'" ~=r(I"'.' ~tI3l1'"

44-415402 06mm 44-415405 32mm 44-415411 /,,"'1"' +50

IX~-f ('/32', C~=O=:::D=f (116., ~I:::;- ("""

44-415403 44-415406.

12mm 44-41

5430 5mm+04 J

I XV4Q3 0::=--[ (1"'" I XV"'[~t ""'., 'XV,,", ,,-~J

~~

SMD 81- Top For Soklering

SDIC & PLCC

-7-

~

--l

,

,

I \

I

~ --"4-

Loading...

Loading...