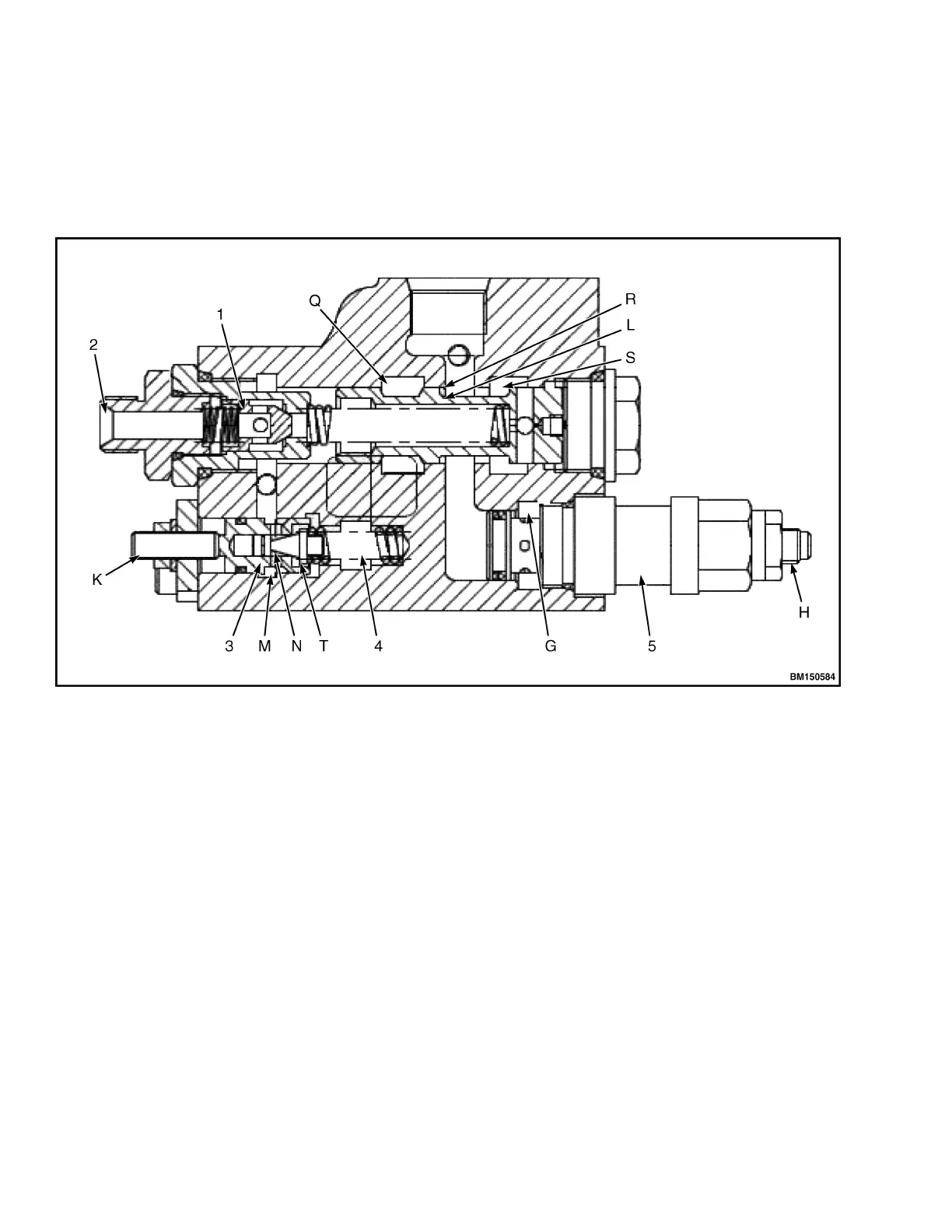

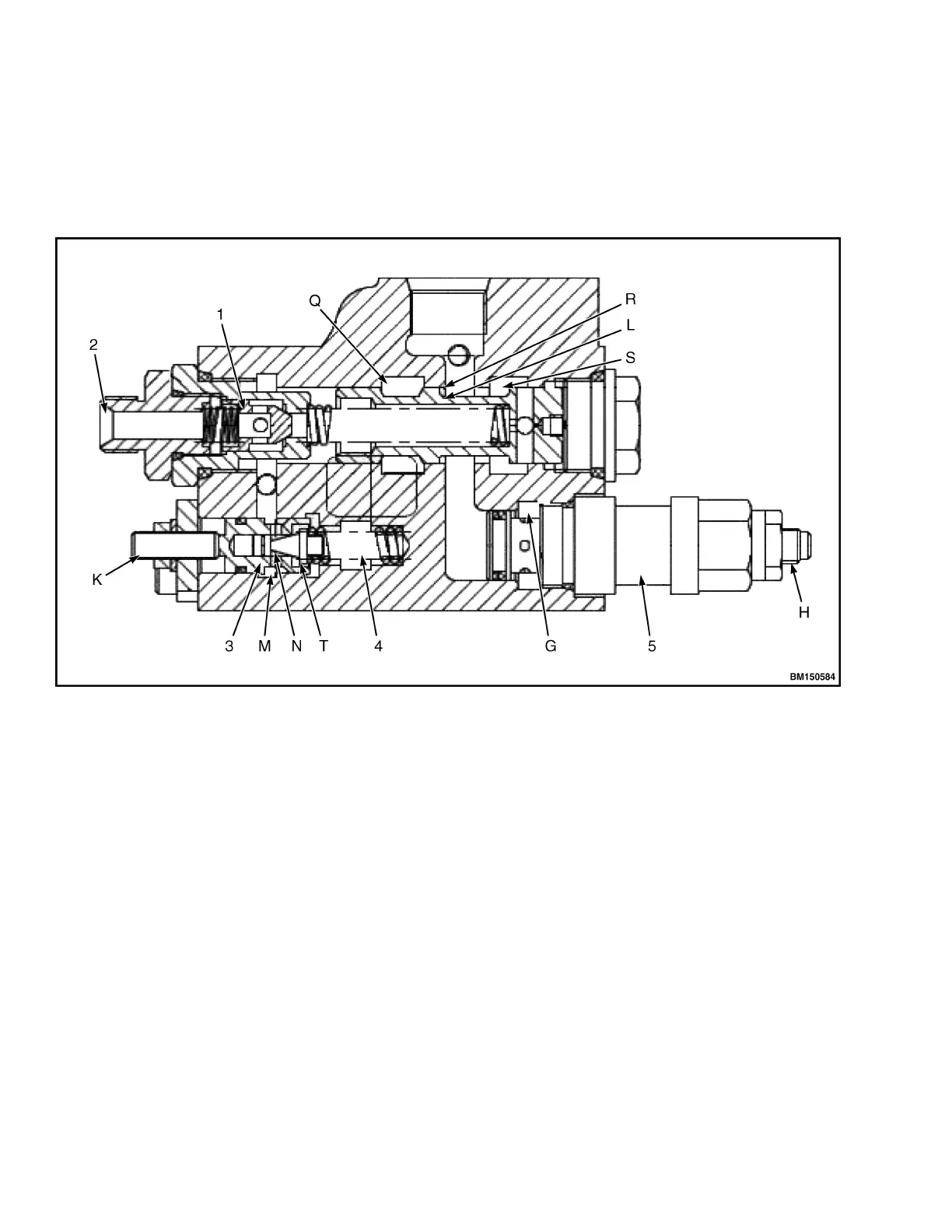

core (N) moves right, and pressure oil is connected

with low-pressure oil circuit through cavity (T), for the

pressure in cavity (M) to lower, in order to ensure the

stability for the pressure of steering system. Adjusting

screw K may be used to adjust the stable pressure

value of the system.

By changing the flow rate and pressure, the slide valve

L moves to the left and right to change the opening of

(R) and (S), to ensure the automatic balance of the

flow rate of the deworking chamber (Q) and PF orifice

and the full hydraulic steering gear, and the flow is

divided stable in proportion

1. ONE WAY VALVE

2. CONNECTING ORBITROL

3. STEERING OVERFLOW VALVE

4. OIL RETURN

5. MAIN RELIEF VALVE

Figure 41. Primary Relief Valve and Priority Spool

Inclined Auto-Lock Valve

The tilt spool valve is fitted with an auto-lock valve to

prevent vibration caused by back pressure inside the

tilt cylinder. It is designed to keep the mast of the lift

truck from "drifting" while a load is raised. The inclined

spool valve can still be operated to tilt backward after

the engine is turned off. However, when this tilt auto-

lock valve is used, a forward tilt can not be performed

when the engine is turned off. See Figure 42 for tilt

auto-lock valve structure.

Hydraulic System 8000 YRM 2199

44

Loading...

Loading...