Proc_Cal_013: Aux 3 Dir B Valve Output Threshold

WHEN TO PERFORM

Performed when troubleshooting procedures indicate,

when Aux 3 Dir B valve components have been serv-

iced, or when the Aux 3 Dir B valve is replaced.

CALIBRATION ORDER

1. Proc_Cal_025

2. Proc_Cal_001

3. Proc_Cal_002

4. Proc_Cal_013

WHY PERFORM

All electro-hydraulic valves have different operating

characteristics. One of the key characteristics is the

point at which hydraulic flow begins for a given com-

mand current. This cracking' current is determined by

this process.

HOW TO PERFORM

WARNING

Keep yourself and all others clear of the lift mech-

anism. Never allow anyone under or on the forks.

Never put hands, arms, head, or legs through the

mast or near the carriage or lift chains. This warn-

ing applies not only to the operator but also the

helper. A helper must not be near the load or the

lift mechanism while the operator is attempting to

handle a load. The lift mechanism has moving

parts with close clearances that can cause seri-

ous injury.

Refer to Table 15 for the procedures on how to per-

form Proc_Cal_013: Aux 3 Dir B Valve Output

Threshold.

Table 15. Proc_Cal_013: Aux 3 Dir B Valve Output Threshold

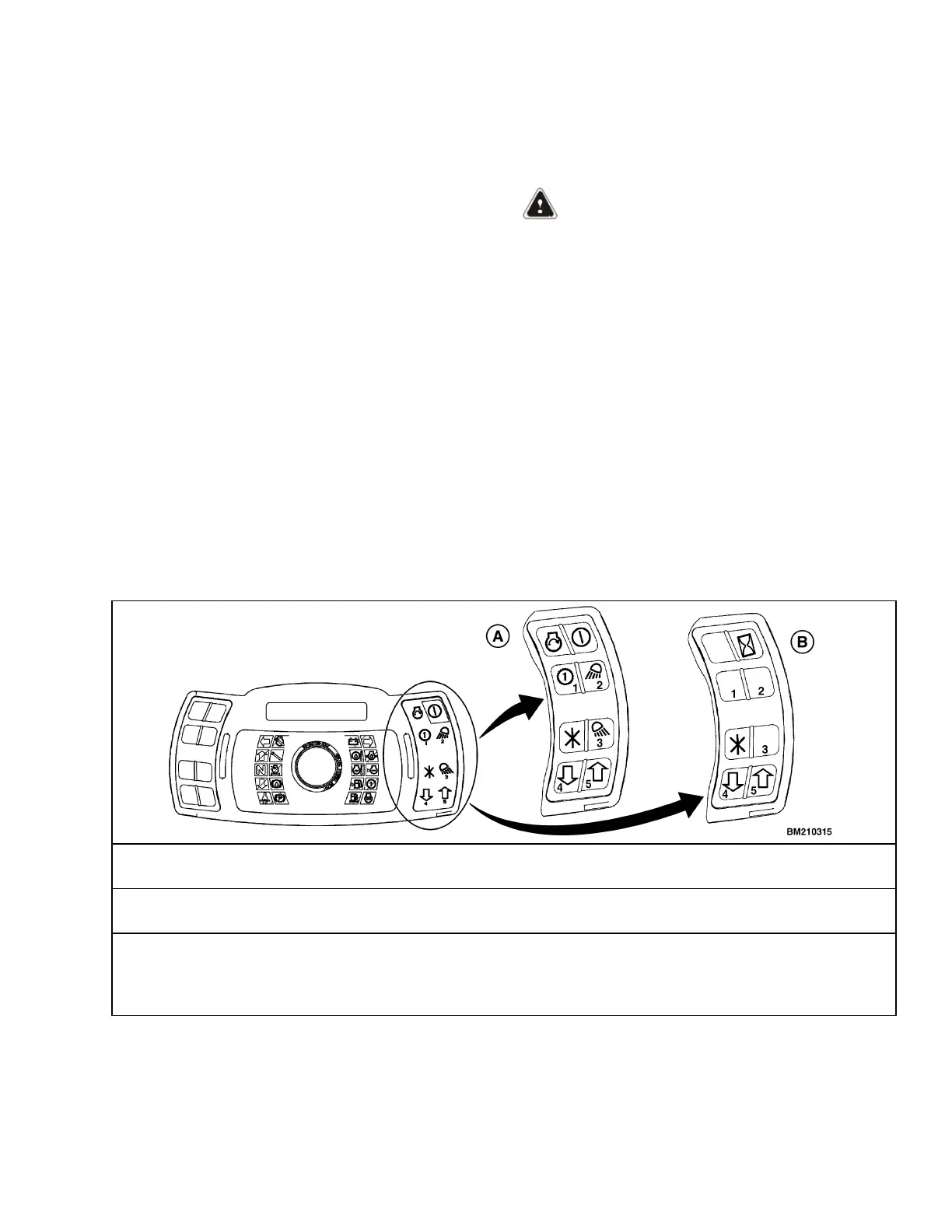

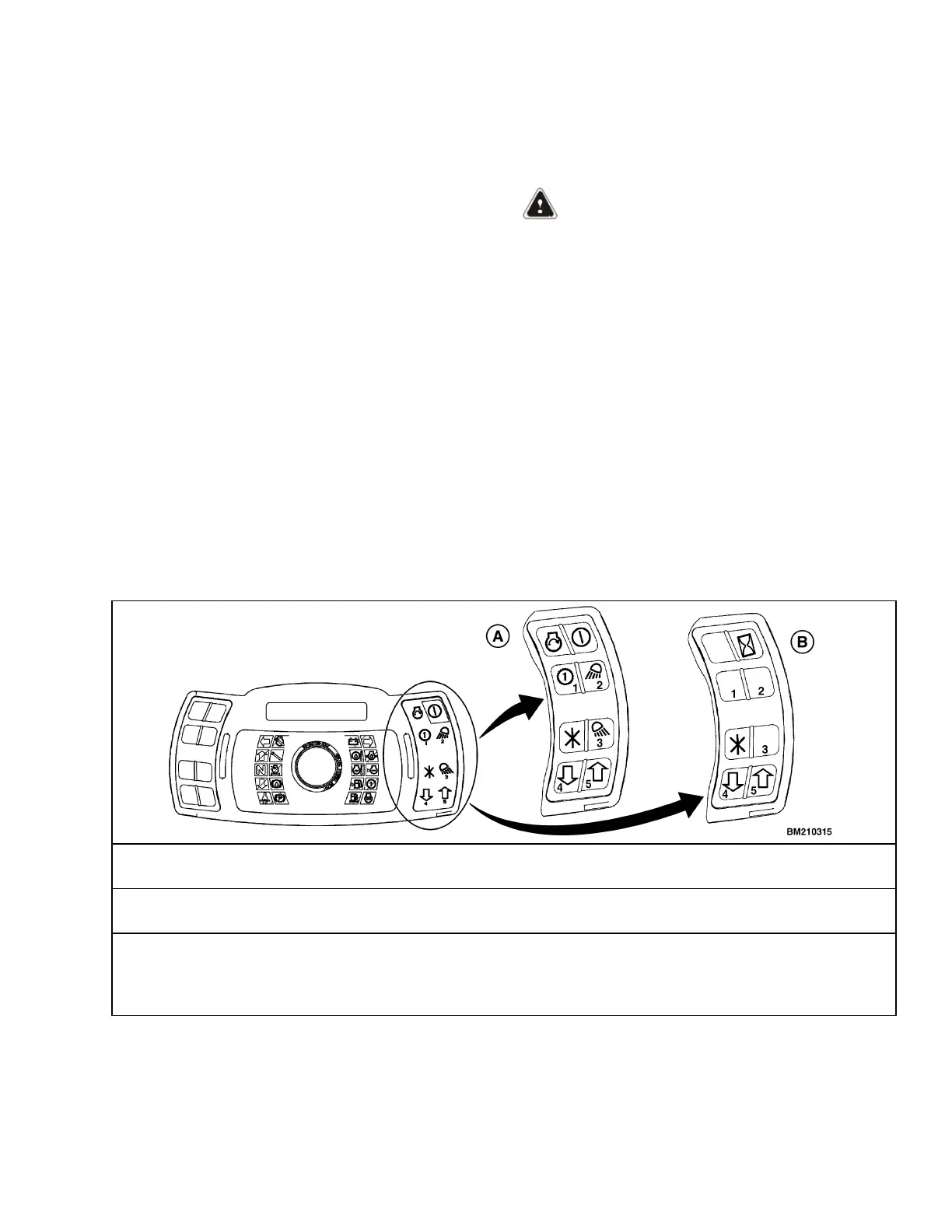

A. TYPICAL DISPLAY WITHOUT KEY, WITH OPTIONS

B. TYPICAL DISPLAY WITH KEY, WITHOUT OPTIONS

Perform Proc_Cal_025: Hydraulic Valve Pressure Gage Installation, Proc_Cal_001: Service Password En-

try, and Proc_Cal_002: Hydraulic Valve Calibration Warm Up and Air Bleed before proceeding.

Information: "Creep" is defined as the threshold when a function first starts to move very slowly (barely percepti-

ble motion). The identification of this motion is defined as the "visual method." The method that provides more

consistent calibration is by monitoring the change in pressure when the function is activated; this is defined as

the "pressure method."

8000 YRM 1134 Proc_Cal_013: Aux 3 Dir B Valve Output Threshold

Confidential/Proprietary - Do Not Copy or Duplicate 37

Loading...

Loading...