CONSTRUCTION OF THIS MANUAL

This manual consists of chapters for the main categories of subjects. (See “Symbols” on the

next page.)

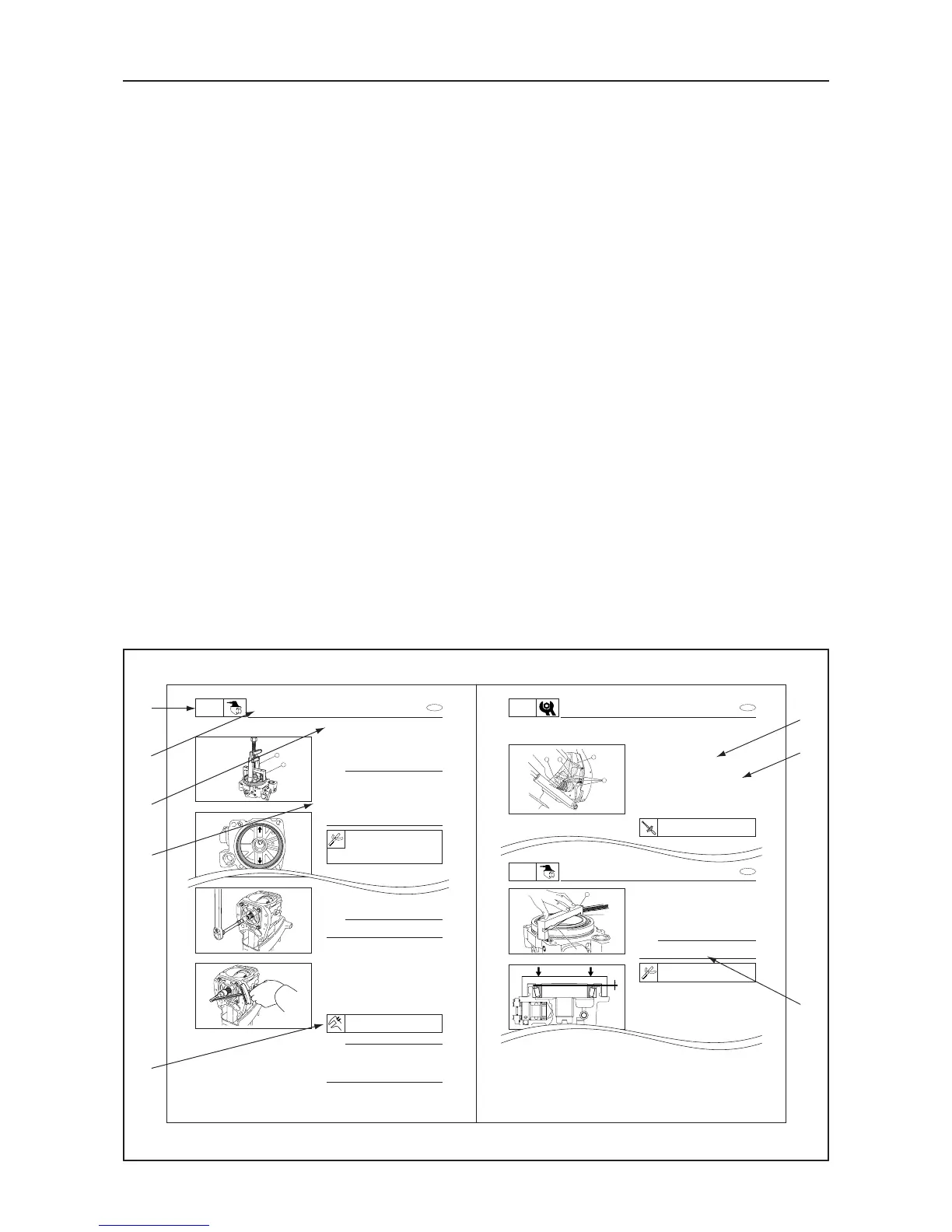

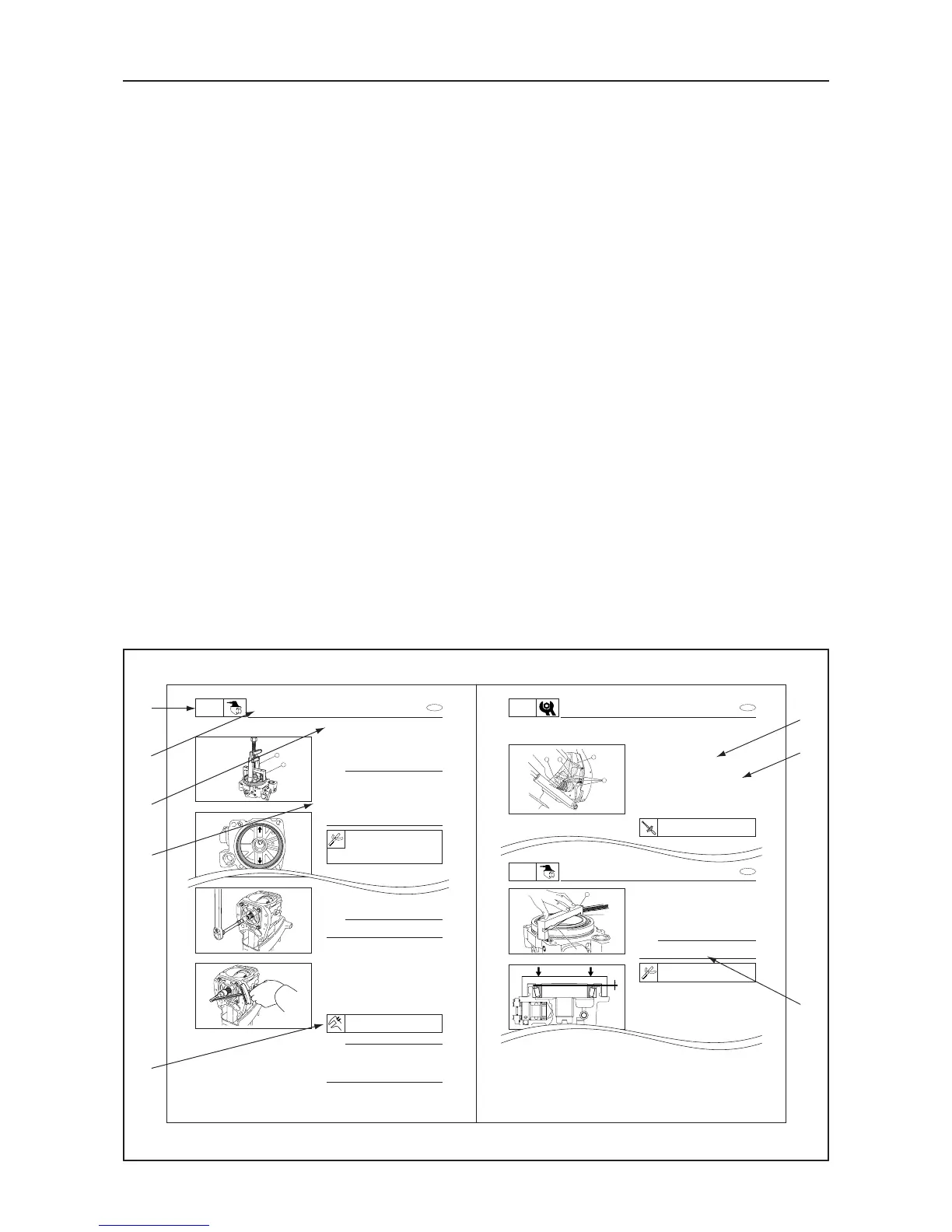

1st title 1 : This is a chapter with its symbol on the upper right of each page.

2nd title 2 : This title appears on the top of the each page, to the left of the chapter symbol.

3rd title 3 : This title precedes the paragraphs describing the working procedure.

All the procedures in this manual are organized in a sequential, step-by-step order. The infor-

mation has been compiled to provide the mechanic with an easy-to-read, handy reference that

contains comprehensive explanations of all disassembly, check, repair, and assembly proce-

dures.

Important procedures including removing, checking, and assembling steps 4 are explained in

detail.

IMPORTANT FEATURES

¡ Important engine data and information about special tools framed in a box together with

an illustrative symbol 5.

¡ A circled numeral 6 indicates a part name. A circled lower case letter indicates data or an

alignment mark 7.

¡ An arrow 8 indicates the course of action required to remedy the started condition of a

component.

EXPLODED DIAGRAM

Each chapter begins with exploded diagrams which facilitate correct disassembly and assem-

bly.

SHIM SELECTION (UPPER UNIT HOUSING)

R-gear Shim (T5) Adjustment

1. Use the guide, bearing puller 2 1 and

the bearing puller 2 to remove the bear-

ing outer race from the selector valve

housing.

NOTE:

¡ When the bearing and the selector valve

housing are not replaced, DO NOT re-

move the bearing outer race.

¡ When replacing the bearing, replace the

total inner and outer set.

¡ Make sure that the bearing puller is set at

the position specified in the illustration.

Guide, bearing puller 2:

6U4-30-3

Bearing puller:

6U4-35

1

2

E

UPPER

UNIT

Drive shaft motive torque (A):

0.4 – 1.5 N·m

3. Loosen the front bearing housing bolts

to 1/2 rotation and measure pre-load B

(motive torque) of the drive shaft.

NOTE:

Measure resistance of the clutch disk section

as the pre-load B (motive torque).

4. Calculate the drive shaft pre-load (mo-

tive torque) based on the pre-load (mo-

tive torque) A and B.

Formula:

Drive shaft pre-load = pre-load (A) – pre-

load (B)

NOTE:

If the drive shaft pre-load (motive torque) is

greater than the specification, reduce the

shim T6b. If the drive shaft pre-load (motive

torque) is less than the specification, increase

the shim T6b.

4-27

T

.

R

Clamp screw:

3 N·m

BELLOWS AND HOSE INSPEC-

TION

1. Inspect:

¡ Shift cable bellows 1

¡ Exhaust bellows 2

¡ Universal joint bellows 3

Cracks/Weathering/Damage → Re-

place.

Loose clamps 4 → Tighten.

Refer to “SWIVEL BRACKET AND

BELLOWS” section (P7-7).

3

12

4

E

INSP

ADJ

BELLOWS AND HOSE INSPECTION

UPPER UNIT HOUSING

3. After inserting the bearing outer race

with press, install the inner race. Use the

shimming tool, T5/T6a 1 to measure the

clearance (Measurement B) between the

tool and the bearing with a thickness

gauge.

NOTE:

To h av e th e cl ea ra nc e, m e as ur e th e li ne b e-

tween the point A and B on the bearing.

4. Find the stamped R-valve of the upper

gear case.

Shimming tool, T5/T6a:

6U4-28

A

B

1

B

E

UPPER

UNIT

1

6

8

7

2

3

4

5

⎧

⎪

⎪

⎪

⎨

⎪

⎪

⎪

⎩

Loading...

Loading...