5-75

Crankcase, connecting rod, and piston

Crankcase disassembly

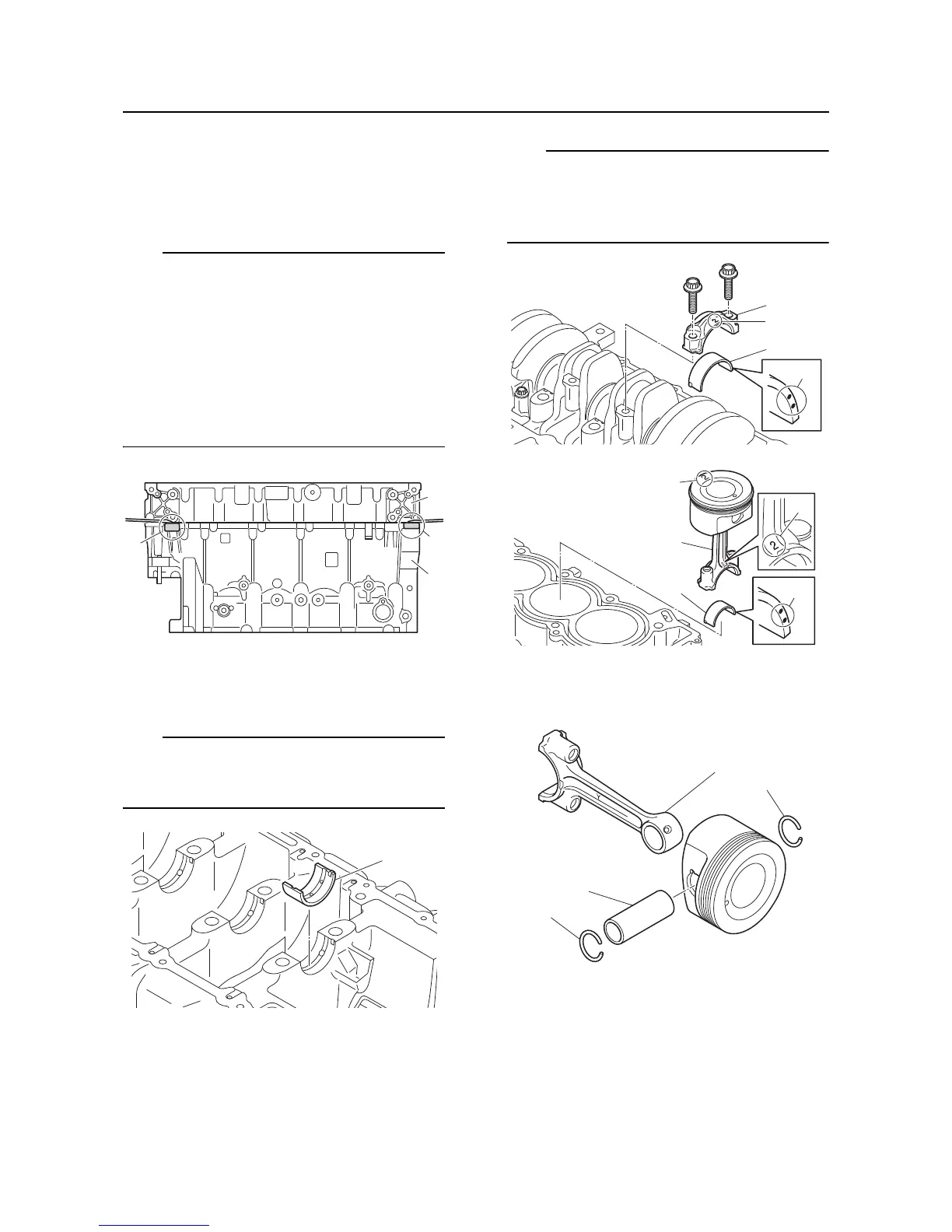

1. Place the crankcase upside down on a

bench.

2. Remove the crankcase “1”.

• Loosen the crankcase bolts in the opposite

order used for tightening.

• The numbers embossed on the crankcase

indicate the crankcase tightening order.

• Insert a flat-head screwdriver between the

reinforced portions “a” of the cylinder block

“2” and the crankcase “1” to separate them.

• Work carefully and make sure that the cylin-

der block and crankcase separate evenly.

3. Remove the crankshaft bearings “1” from

the crankcase.

Write down the position of each crankshaft

bearing “1” so that it can be installed in its orig-

inal position.

Connecting rod and piston removal

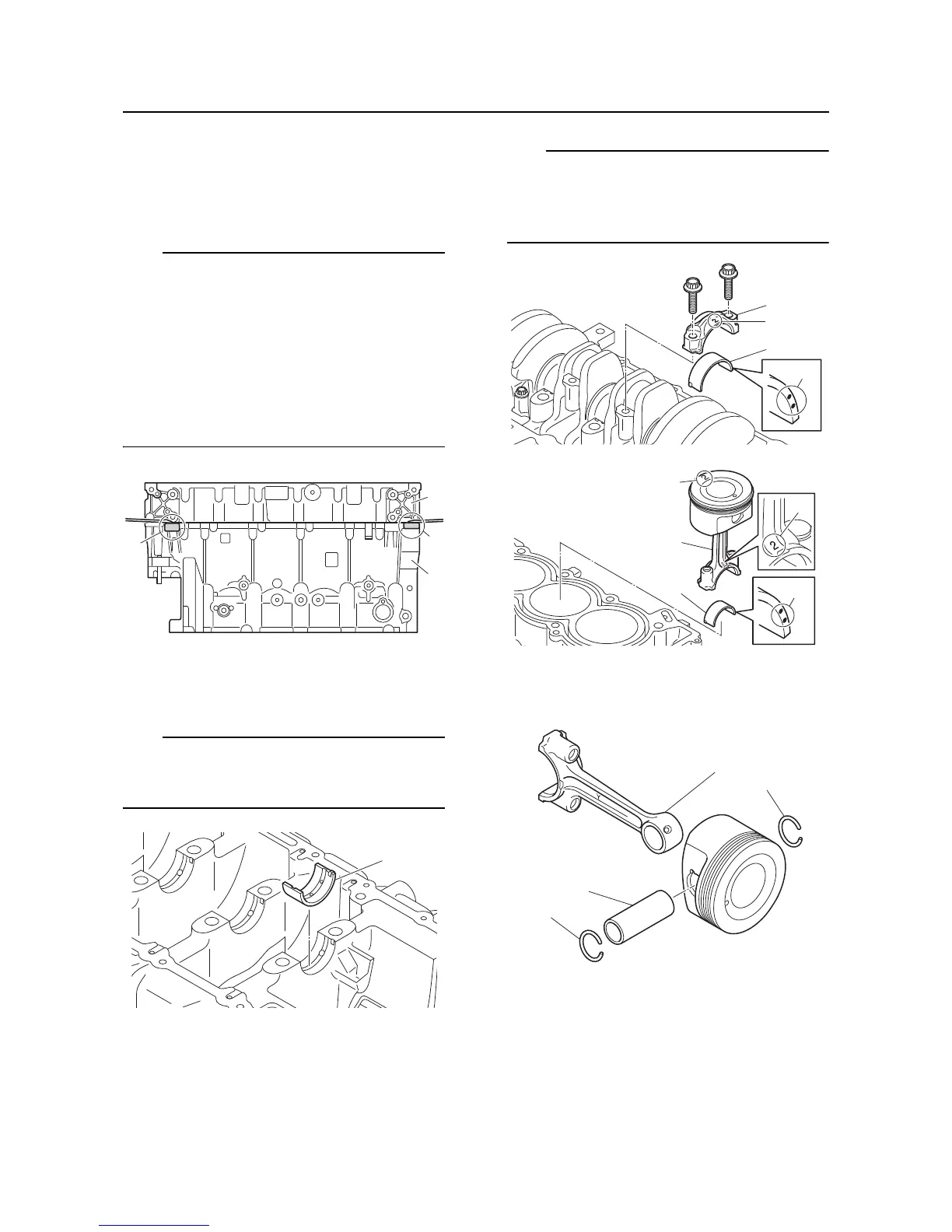

1. Remove the connecting rod cap “1”, and

then remove the connecting rod bearings

“2” and piston and connecting rod “3”.

For reference during installation, make identifi-

cation marks “a” on the connecting rod cap,

connecting rod, connecting rod bearings, and

piston crown.

2. Remove the piston pin clips “1”, piston pin

“2”, and connecting rod “3”.

3. Remove the piston rings.

Crankcase check

1. Check the oil passages. Blow out using

compressed air if there are obstructions.

Loading...

Loading...