Service

77

5)

Cleaning battery

Keep battery clean by wiping

it

with a clean

cloth every

50

hours operation or whenever

dirt appears excessive. Remove any corro-

sion, and wash terminals with a solution of

baking soda and water.

Check vent holes

in

the battery caps to make

sure -they are open. Cable connectors must

be free of dirt and well tightened.

Tighten connectors to reduce corrosion.

.

.

6)

Storing banery

A

CAUT,ON

Store

battery

out

of reach of children.

If tractor is stored for the winter or for any

period of

30

days or more, remove the

battery and store in a cool dry place where

no freezing will occur. Check the battery

every

30

days and charge them if necessary.

7)

Cold weather battery service

Battery has less capacity in cold weather and

carries a heavier load in starting the engine,

and therefore require more attention.

oritive

banery

cable

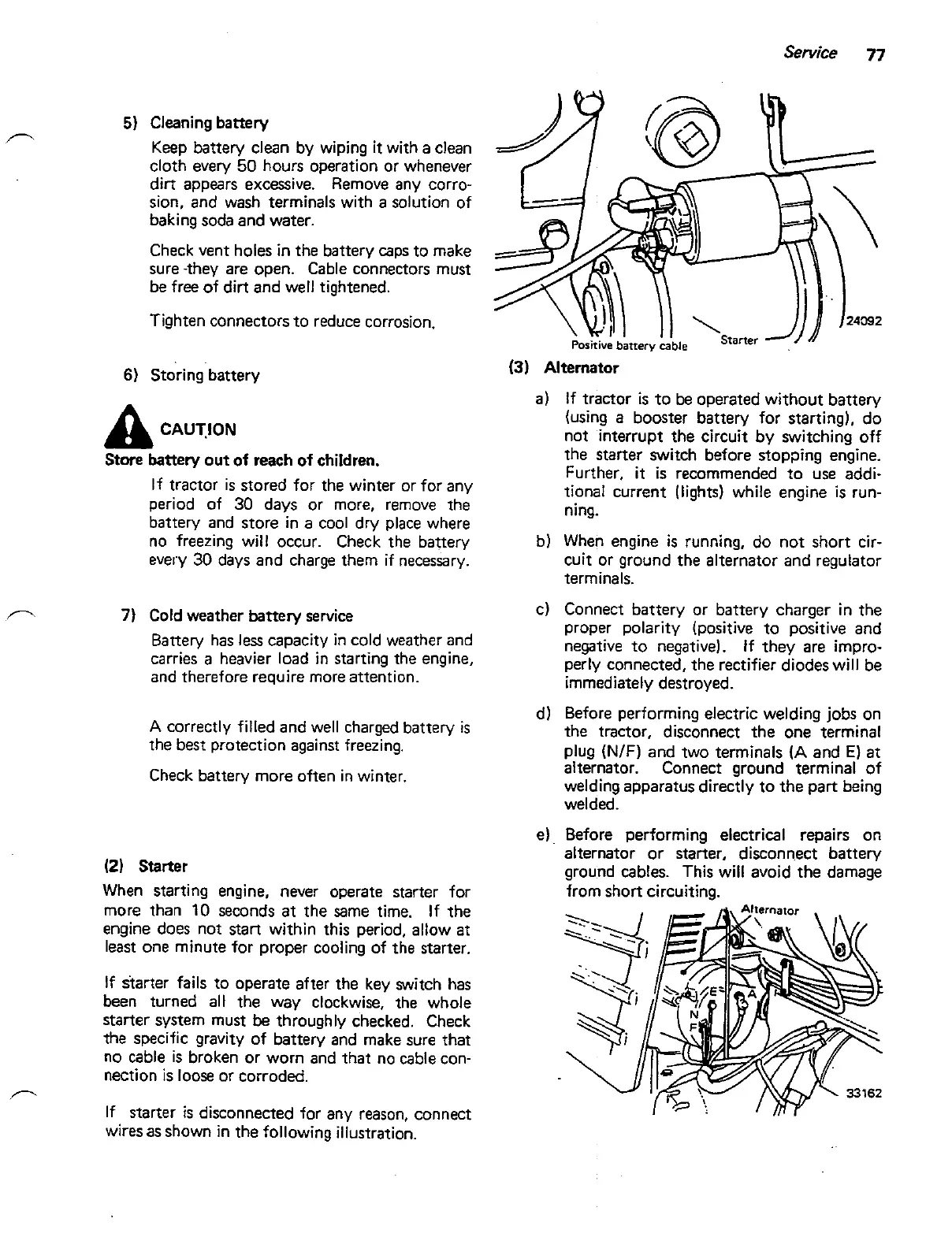

(3)

Alternator

a)

If

tractor

is

to

be

operated without battery

(using a booster battery for starting), do

not interrupt the circuit by switching off

the starter switch before stopping engine.

Further,

it

is recommended to use addi-

tional current (lights) while engine is run-

ning.

b) When engine

is

running, do not short cir-

cuit or ground the alternator and regulator

terminals.

A

correctly filled and well charged battery

is

d)

the best protection against freezing.

Check battery more often in winter.

C)

Connect battery or battery charger in the

proper polarity (positive to positive and

negative to negative). If they are impro-

perly connected, the rectifier diodes will be

immediately destroyed.

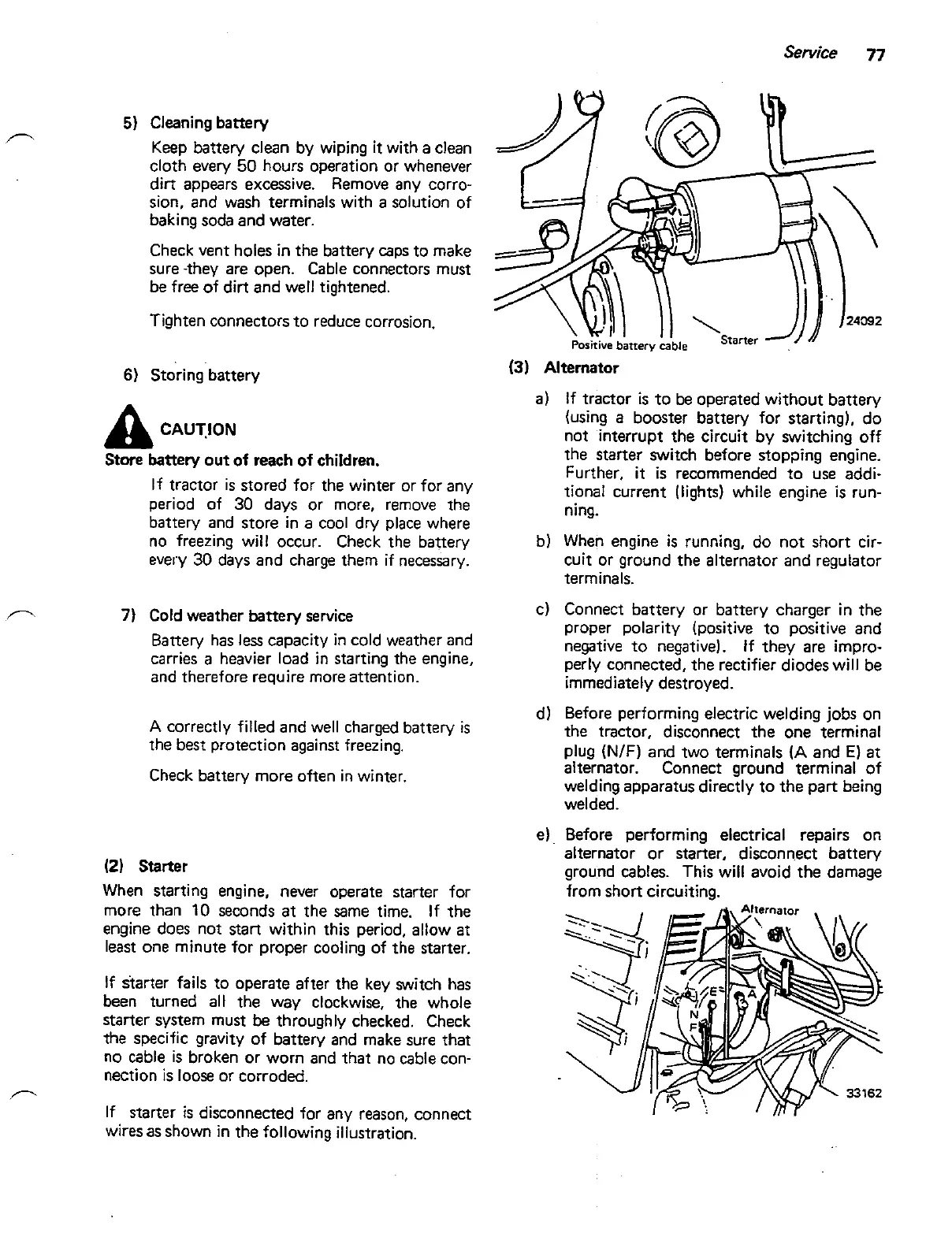

(2)

Starter

When starting engine, never operate starter for

more than

10

seconds at the same time. If the

engine does not start within this period, allow at

least one minute for proper cooling of the starter.

If starter fails to operate after the key switch has

been turned all the way clockwise, the whole

starter system must

be

throughly checked.

Check

the specific gravity of battery and make sure that

no cable is broken or worn and that no cable con-

nection is loose or corroded.

/-.

If starter

is

disconnected for any reason, connect

wires as shown in the following illustration.

Before performing electric welding jobs on

the tractor, disconnect the one terminal

plug

(N/F)

and two terminals

(A

and

E)

at

alternator. Connect ground terminal of

welding apparatus directly to the part being

welded.

Before performing electrical repairs on

alternator or starter, disconnect

battew

ground cables. This will avoid the damage

from short

circuiting.

Loading...

Loading...