Catalog

|

KAEP C710617 24

|

YASKAWA

1

:

Remove the insulator from the tips of wires to the length shown in

“

Wire

3

:

Terminals - and

+

have two screws. Recommended Gauge means the wire

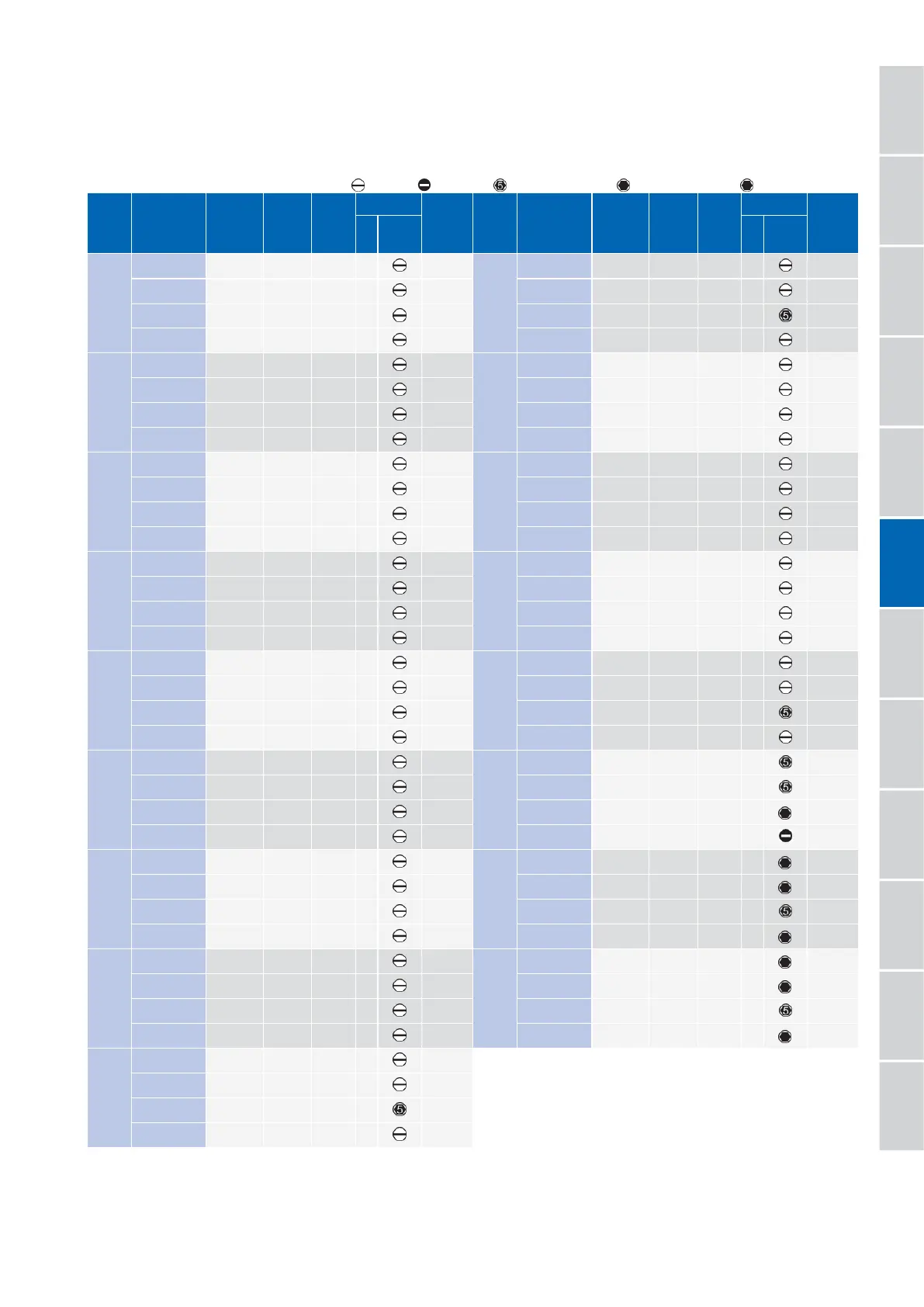

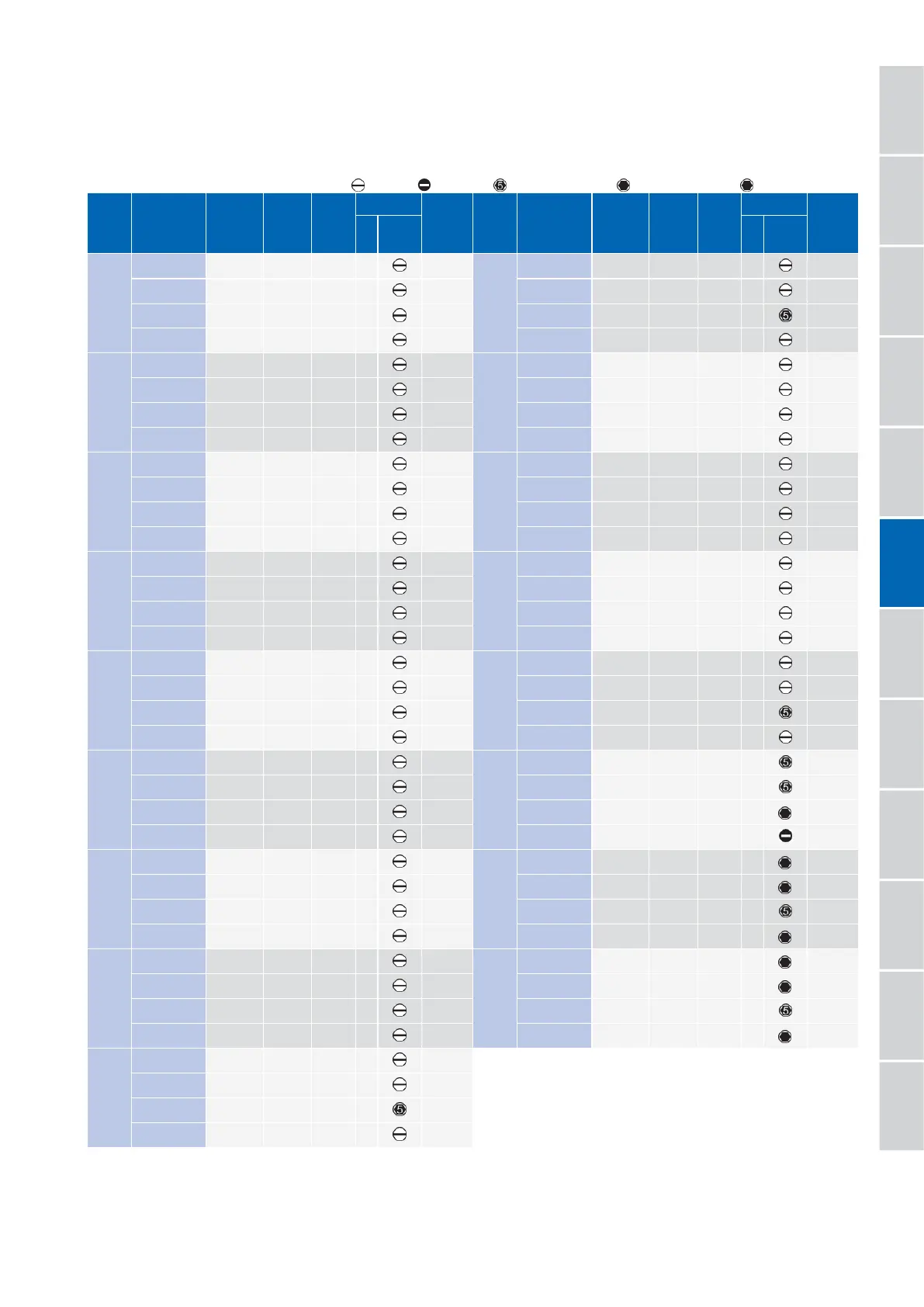

400 V Class

Symbols indication the shape of the terminal screws

:

:Slot

(

-

)

, :Minus

(

-

)

, :Hex socket

(

WAF

:

5

)

,

:Hex socket

(

WAF

:

6

)

,

:Hex socket

(

WAF

:

8

)

*

Stripping Length.

”

2

:

When using wire with a gauge over

30

mm

2

, tighten to a tightening torque of

4

.

1

to

4

.

5

N

・

m.

*

gauge of one terminal.

4

:

Use cables in the range of applicable gauges to meet the IP

20

protective level.

5

:

A junction terminal is required when connecting a braking unit

(

CDBR

-

series

)

*

or a braking resistor unit

(

LKEB

-

series

)

.

Note

:

The recommended wire gauges based on drive continuous current ratings

using

75

˚C

600

V class

2

heat resistant indoor PVC wire.

Assume the following usage conditions

:

·

Ambient temperature

:

40

˚C or lower

·

Wiring distance

:

100

m or shorter

·

Rated current value

Fully

-

Enclosed

Design and

Drive

Watt Loss Data

Model Number/

Catalog Code /

Selecting

the Capacity

Peripheral

Devices

and Options

Specifications

Connecti

on Diagram

Specifications

Wire Range

(

IP20

Compatible

Gauge

)

mm

2

Wire

Stripping

Length

*

1

mm

Wire Range

(

IP20

Compatible

Gauge

)

mm

2

Wire

Stripping

Length

*

1

mm

Loading...

Loading...