13

The Controller… In-Depth

This is an in-depth overview of the controller’s feature set.

The controller has been designed to make it as hands-off and user-friendly as possible. At its most basic

level, the cooker has three modes of operation: Heat-up, Maintenance and Cool Down.

Beyond these basic modes are the concepts of aggressiveness, anticipation and micromanagement that

have been learned as the result of many thousands of hours of testing. When the cooker is displaying

maintenance mode, it is not idle. It is constantly checking and re-evaluating the grill’s temperature and

making incremental adjustments to maintain the cooking temperature as close to the desired set point as

possible – think of it as micromanagement.

Just like in the maintenance mode, the controller is constantly evaluating the grill status while in “heat

up” and “cool down” modes. This is where “aggressiveness” and “anticipation” have been written into

the program. If the controller senses the grill is not heating up very quickly, it will increase the pellet feed

rate above what the normal heat up rate would be for a given set point, and it will continue to do so

until the heat up rate is where it should be. The inverse is true of the cool down mode – if the grill is not

cooling fast enough, the controller will get more aggressive with cool down until the grill temperature is

where it should be.

How the Heat Up Modes Work

In addition to the intelligence previously described, the program also contains three internal heat up

modes. Left on its own, the controller makes a series of small incremental adjustments as described

above. The various heat up modes are designed to speed the heat up process.

The selection of the heat up modes is automatically selected by the program. At startup the program

automatically begins in H1. 8 minutes into the start-up cycle, the program calculates the diff erence

between the set point and the actual cooker temperature and changes the “H” mode if necessary. The

program will make the same calculation again at the 12-minute mark, and if an “H” mode other than the

mode currently running is required, the program makes the required change. If a mode other than H1 has

been selected, it will remain in that mode until it breaks that target set point at which time the program

will enter maintenance mode.

Once the controller enters maintenance mode, the pit temperature must rise or fall 35 degrees above or

below set point before the program enters the heat up or cool down mode.

46

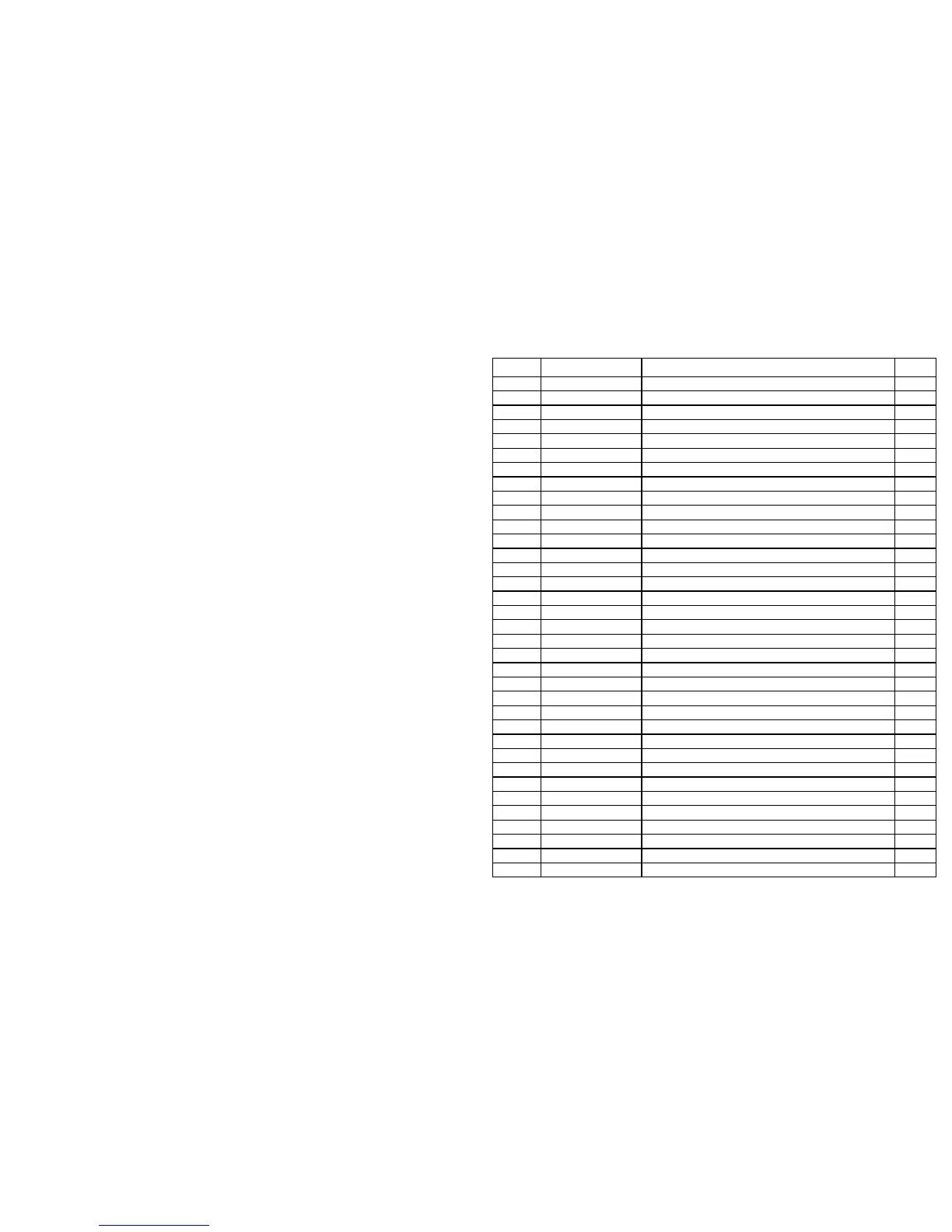

ITEM # PART # DESCRIPTION

QTY.

1 90101 BODY, FRONT, FEED COMPARTMENT 1

2 90102 BULKHEAD, MOUNT, HOPPER 1

3 90106 COVER, END, FEED COMPARTMENT 1

4 W90791 HOPPER, PELLET SMOKER 1

5 90022 BUSHING, AUGER 1

6 90023 BUSHING, AUGER 1

7 W90019 AUGER 1

8 90027 PLATE, ANTI-TORQUE 1

9 90001 MOTOR, PELLET AUGER 1

10 90060 INNER FAN, 115 CFM 1

11 1420X12SHCS SOCKET HEAD CAP SCREW, 1/4-20 X 0.05 LONG 2

12 10X34HHSDS SCREW, HEX HEAD, SELF DRILLING 10 X 3/4 37

13 A90152 CONTROLLER 1

14 516X12SHSB SCREW, SHOULDER, .313 X .50, SOCKET HEAD 1/4-20 1

15 51618X12SHSS SCREW, SET, SOCKET HEAD, 5/16-18 X 1/2 1

16 1024X12HHSTS SCREW, SLOTTED, HEX HEAD, SELF TAPPING, 10-24 X 1/2 4

17 22866 HANDLE, SPRING 1

18 1420WHN NUT, WHIZ, 1/4-20 1

19 W90790 HOPPER BACK 1

20 W90788 HOPPER DOOR 1

21 90312 SOCKET, 15 AMP 1

22 632X38MS SCREW, MACHINE, ROUND HEAD, 6-32 X 3/8 LONG 4

23 632HN NUT, HEX, 6-32 4

24 832HN NUT, HEX, 8-32 4

25 91435 FUSE, 1.6A 1

26 90412 FUSE HOLDER 1

27 W90553 FAN HOUSING 1

28 832X12MS SCREW, MACHINE, PHILLIPS HEAD, 8-32 X 1/2 LONG 4

29 90686 OUTER FAN, 68 CFM 1

30 90893 PLATE, FAN AIR DIVERTER 1

31 23985 VELCRO 1

32 90313 POWER CORD 1

33 W90026 IGNITER TUBE 1

34 A90494 IGNITER ASSEMBLY 1

35 1420X14SHSS SCREW, SET, SOCKET HEAD, 1/4-20 X 1/4 4

HOPPER ASSEMBLY

Loading...

Loading...