ate the system down to at least 500 microns to eliminate

contamination and moisture in the system.

” on page 9 for checking and

GENERAL INFORMATION & GROUNDING

Check the electrical supply to be sure that it meets the values

specified on the unit nameplate and wiring label.

Power wiring, control (low voltage) wiring, disconnect

switches and over current protection to be supplied by the

installer. Wire size should be sized per NEC requirements.

The complete connection diagram and schematic wiring label

is located on the inside surface of the unit electrical box cover

FIELD CONNECTIONS POWER WIRING

Install the proper size weatherproof disconnect switch

outdoors and within sight of the unit.

Run power wiring from the disconnect switch to the unit.

Remove the control box cover to gain access to the unit

wiring. Route wires from disconnect through power wir-

ing opening provided and into the unit control box as

Install the proper size time-delay fuses or circuit breaker,

and make the power supply connections.

Energize the crankcase heater to save time by preheat-

ing the compressor oil while the remaining installation is

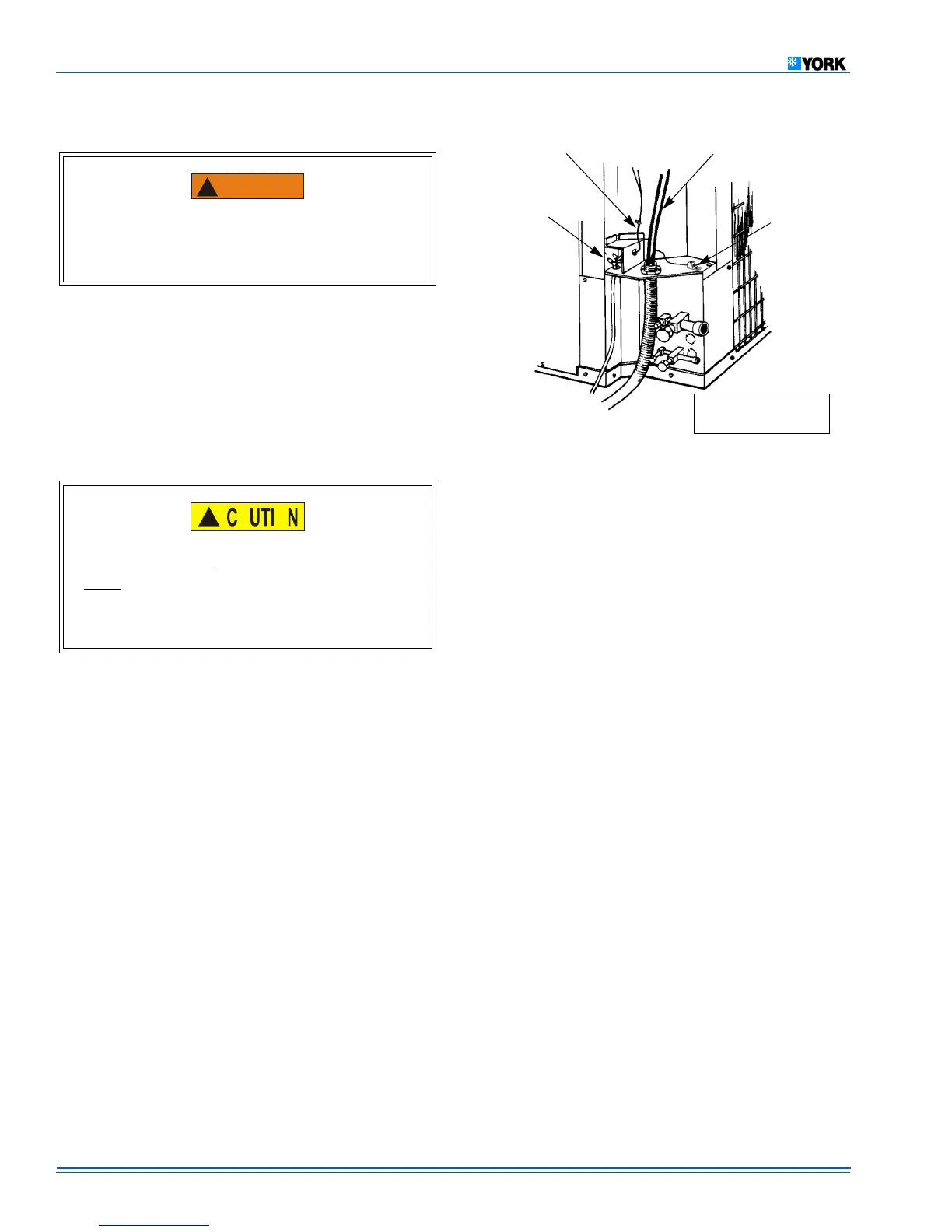

FIELD CONNECTIONS CONTROL WIRING

Route low voltage wiring into bottom of control box as

shown in Figure 7. Make low voltage wiring connections

inside the junction box per Figures 8, 9, 10 or 11.

The complete connection diagram and schematic wiring

label is located on the inside surface of the unit electrical

All field wiring to be in accordance with national electrical

codes (NEC) and/or local-city codes.

A Start Assist Kit is available and recommended for

long line set applications or in areas of known low volt-

age problems. A hard start kit must be used if a solenoid

valve accessory or non-bleed type expansion device is

Mount the thermostat about 5 ft. above the floor, where it

will be exposed to normal room air circulation. Do not

place it on an outside wall or where it is exposed to the

radiant effect from exposed glass or appliances, drafts

from outside doors or supply air grilles.

Route the 24-volt control wiring (NEC Class 2) from the

outdoor unit to the indoor unit and thermostat.

To eliminate erratic operation, seal the hole in the wall

at the thermostat with permagum or equivalent to pre-

vent air drafts affecting the anticipators in the thermo-

The factory charge in the outdoor unit includes enough

charge for the unit and a most sold matched evaporator.

Some indoor coil matches may require some additional

charge. See Tabular Data sheet provided in unit literature

Sweat connect units also include sufficient charge for 15 feet

of lines. See Tabular Data for charge adder for line lengths

Never attempt to repair any brazed connections while

the system is under pressure. Personal injury could

and be in accordance with Local, National Fire,

Safety & Electrical Codes. This unit must be grounded

with a separate ground wire in accordance with the

Loading...

Loading...