035-19699-001-B-0804

Unitary Products Group 5

CLEANING BURNERS

Remove them from the furnace as explained in

BURNER INSTRUCTIONS section in the Unit Installa-

tion Instructions. Clean burners with wire brush and

vacuum as needed.

CLEANING FLUE PASSAGES AND

HEATING ELEMENTS

With proper combustion adjustment, the heating ele-

ment of a gas fired furnace will seldom need cleaning.

If the element should become sooted, it can be cleaned

as follows:

1. Remove the burner assembly as outlined in

“BURNER INSTRUCTIONS” of the unit installation

instructions.

2. Remove the unit roof from over the gas heat section.

3. Remove the top plate and the top draft blower

wheel from the upper draft blower housing.

4. Remove the screws holding the top of the flue col-

lector box. Carefully remove the top of the flue col-

lector box without ripping the adjacent insulation.

Then remove the center divider plate separating

the upper and lower flue boxes.

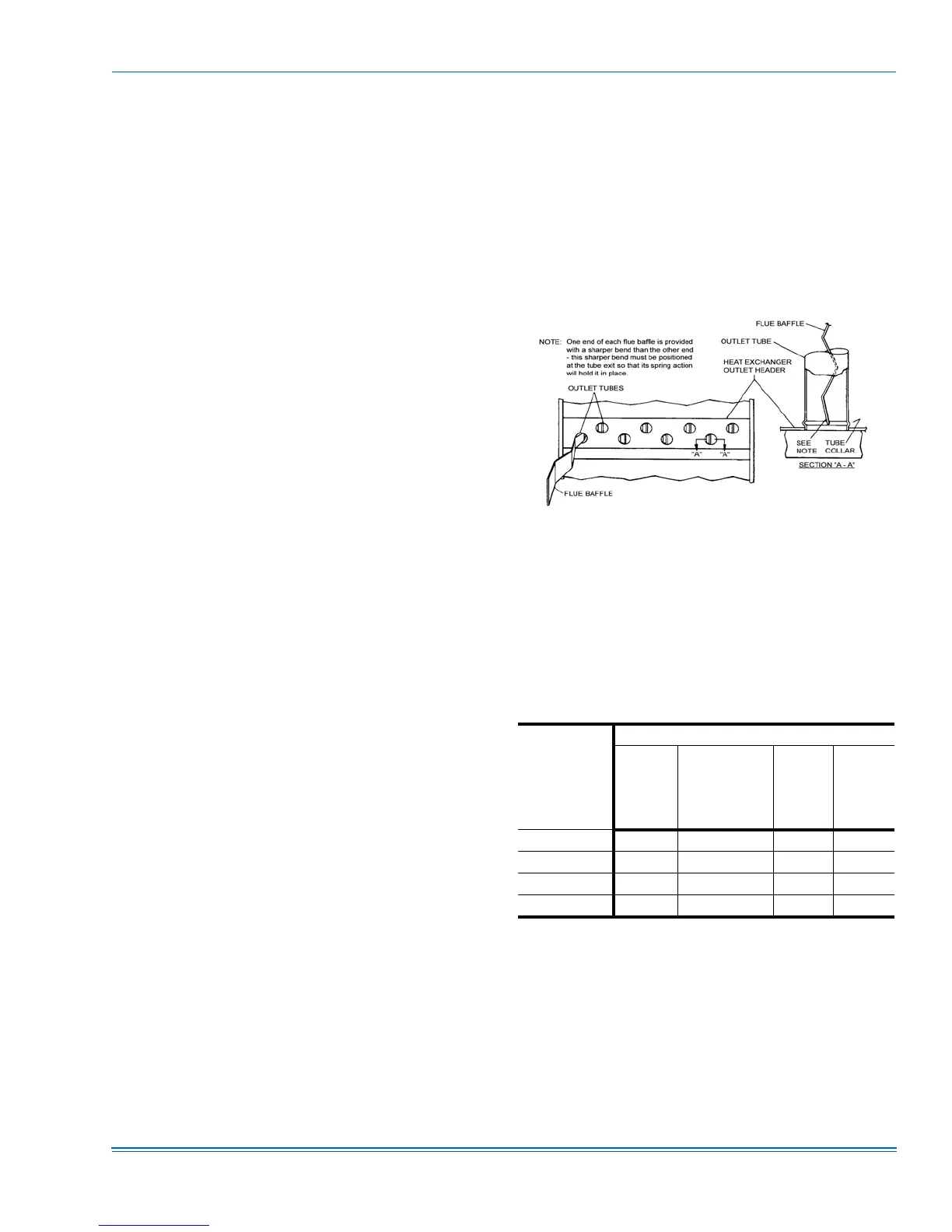

5. On the inside of the flue collector box, remove the

flue baffles from the tube interiors. Note the last

bend of the baffle fits tightly against the tube forc-

ing the end of the baffle to lock into the tube collar.

This collar is formed when the tube is expanded

into the end sheet. To remove, move the end of the

baffle toward the center of the tube releasing the

end of the baffle from the tube collar, then pull

straight out of the tube. Refer to Figure 4.

6. Using a wire brush on a flexible wand, brush out

the inside of each heat exchanger from the burner

inlet and flue outlet ends.

7. Brush out the inside of the flue collector box and

the flue baffles.

8. Run the wire brush down the vent hoods from the

flue collector end.

9. If soot build-up is particularly bad, remove the vent

motor and clean the wheel and housings. Run the

wire brush down the flue extensions at the outlet of

the vent housings.

10. After brushing is complete, blow all brushed areas

with air or nitrogen. Vacuum as needed.

11. Replace parts in the order they were removed in

Steps 1 thru 5.

12. When replacing the center and top of the flue col-

lector box, be careful not to tear the adjoining insu-

lation.

13. Ensure that all seams on the vent side of the com-

bustion system are air tight. Apply a high tempera-

ture (+500°F) sealing compound where needed.

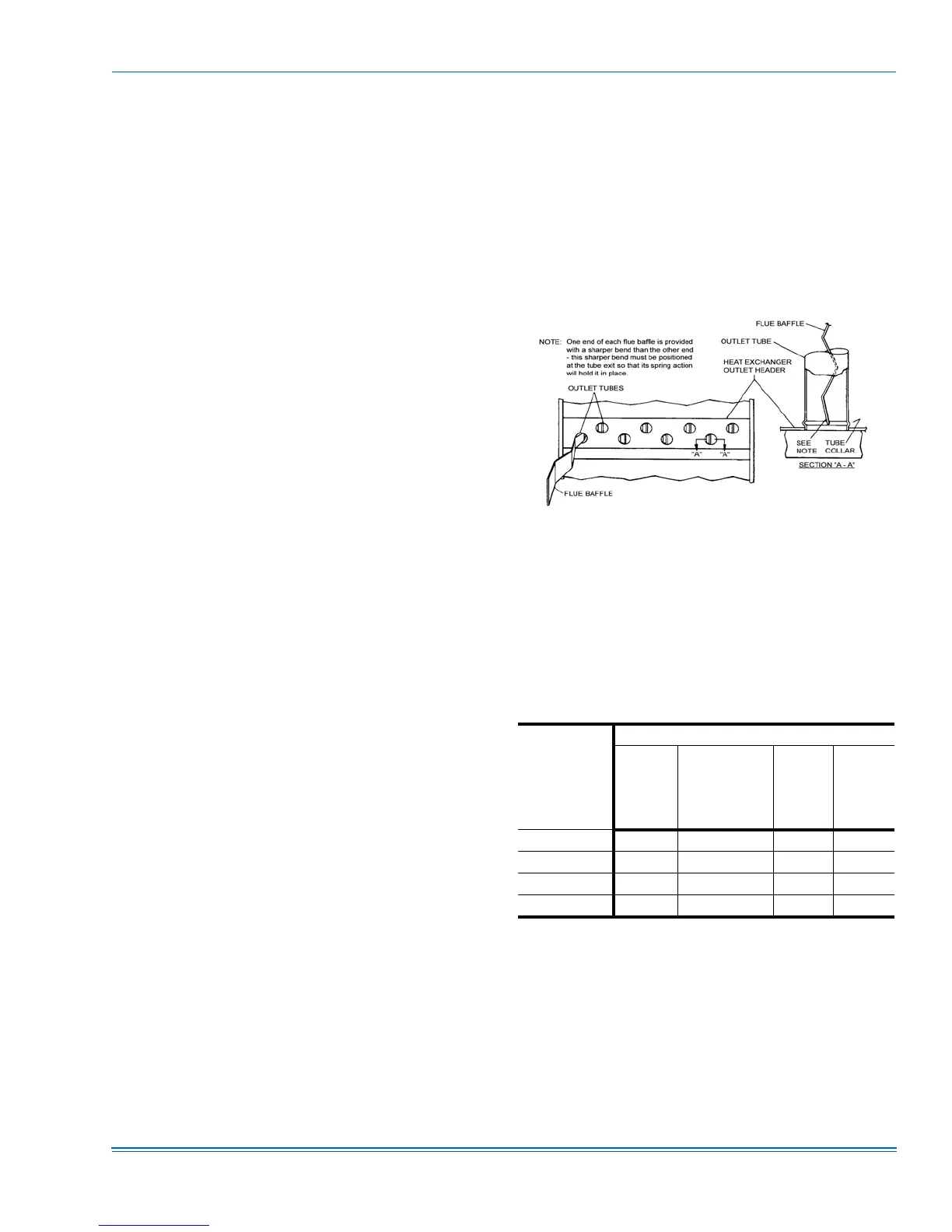

AIR FILTERS

All units contain 2" filters. Filters can be installed in the

building at a suitable return air location if an econo-

mizer or outside air accessory is not used. Filters must

always be used. They should be inspected once a

month and thoroughly cleaned or replaced if it appears

they are beginning to accumulate excessive dirt. Filter

sizes and quantities are shown in the following table.

To install the filters, remove the filter access panel

located to the left of the condensate drain connection

as shown in Figure 5.

NOTE: Filters must be installed with “Air Flow” arrows

pointing inward -- toward the indoor coil. In the

event the spacers in the filter section are

removed, they must be reinstalled in their origi-

nal position.

FIGURE 4 - TYPICAL FLUE BAFFLE INSTALLATION

THROWAWAY

FILTER

SIZES

(Inches)

QUANTITY PER UNIT (Nom, Tons)

15 TON

STD

& HIGH

EFF.

15, 20, 25

TON REHEAT

20 TON

STD & HIGH

EFF.

25 TON

STD

EFF.

15 - 25

TON

ULTRA

HIGH

EFF.

12 x 24 - - 12 12

16x 20 - 4 - -

16 x 25 - 4 - -

18 x 24 5 - - -

Loading...

Loading...