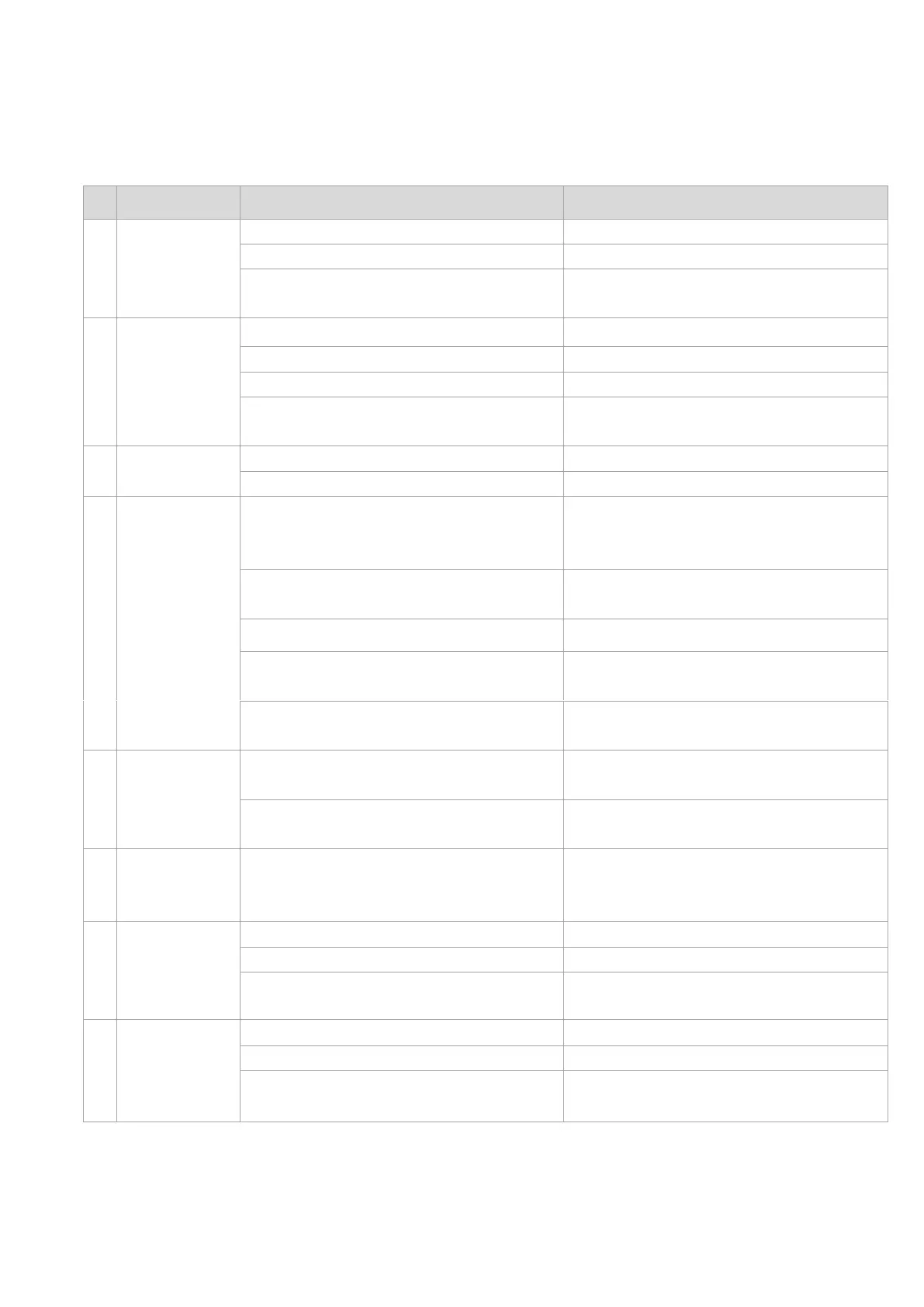

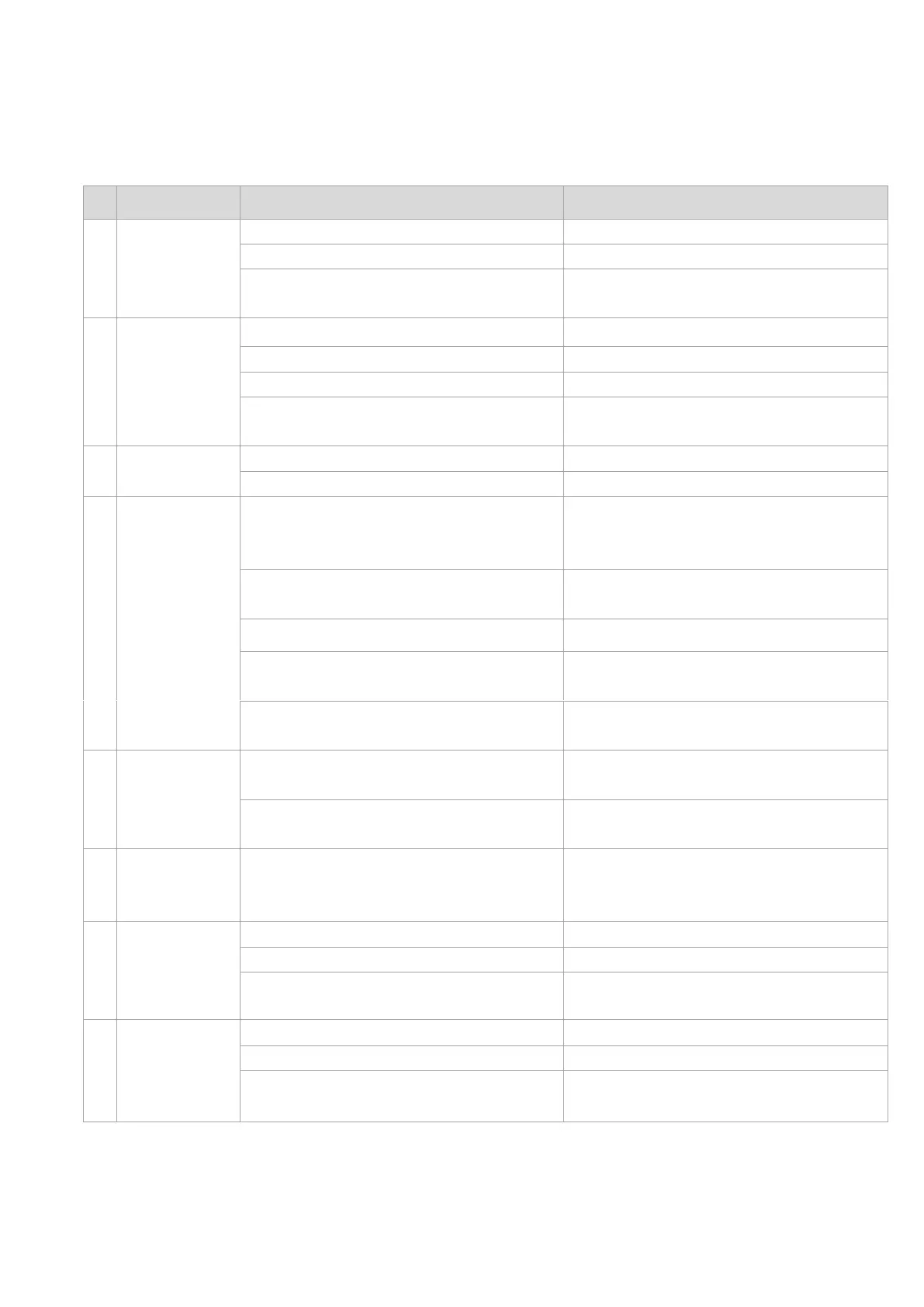

50

Chapter5 Troubleshooting

The equipment

can’t be turned on

Check if the emergency stop button is pressed down

Release the emergency stop button

Main contactor in electrical b ox trips

Check if the front cover and back cover are put

properly and if the cover opening protection is closed

Put on the front cover and back cover properly

Water-cooling system isn’t turned on normally

Turn on the water circulation system

Water protection is not triggered

Check if the chiller is working properly

Laser system isn’t turned on

Press the laser power button

Laser power supply is damaged

Replace the switching power supply of the same

specifications

Laser pause

during working

Check if water circulation is smooth

Clean water tank, dredge water hose

If power voltage is table

Install a stabilizer to input power supply

User adopts PLT output in CoreIDraw software. In

HGPL dialogue box, if unit of plotter in page option is

set correct

PLT plotter unit out from CoreIDraw software should

match with resolution of SmartCarve software lead-in

PLT option

User adopts PLT output in CoreIDraw software. In

HGPL dialogue box, if zooming in page option is 100%

If resolution of the mainboard parameters are correct

Set to the correct resolution or equivalent

Fail to connect earthing for the mainboard or other

interferences

Connect earthing, eliminate the interference

Over high temperature causes crash to the

mainboard

Add more measures for lowering temperature

Equipment crash

and carving

Laser tube (high voltage) discharges to the housing

and sparks

Reconnect the high-voltage line of the laser tube

Board isn’t grounded or other interference

Connect the ground wire properly and eliminate

interference

Reverse direction

of motor shaft

movement

If lines from the drive to the motor are connected

improperly, and drive parameter settings are correct

Check electric earthing and drive parameter settings

Fail in movement

of motor shaft or

twittering of it

during movement

Improper setting of motor parameters

Set to the correct movement parameters

Change the drive or motor

Change the drive or motor

Reconnect the motor and drive line

Cutting graphics

and drawing

sizedo not match

Check the procedures according to the figure

Synchronous belt is loose

Tension the synchronous belt

Control system is damaged

Check the stepper motor and drive, and replace if

damaged

Loading...

Loading...