36

6. MAINTENANCE

Proper maintenance is crucial for durability of the machine in operation and optimum performance and to ensure

the security provided by the manufacturer.

For reliable use in time of the group it is necessary to make a limited number of routine maintenance operations.

For this follow the instructions of the booklet Maintenance 0MDL178 (provided with the documentation supplied

with the unit) to which we give the maintenance schedule based on hours of operation:

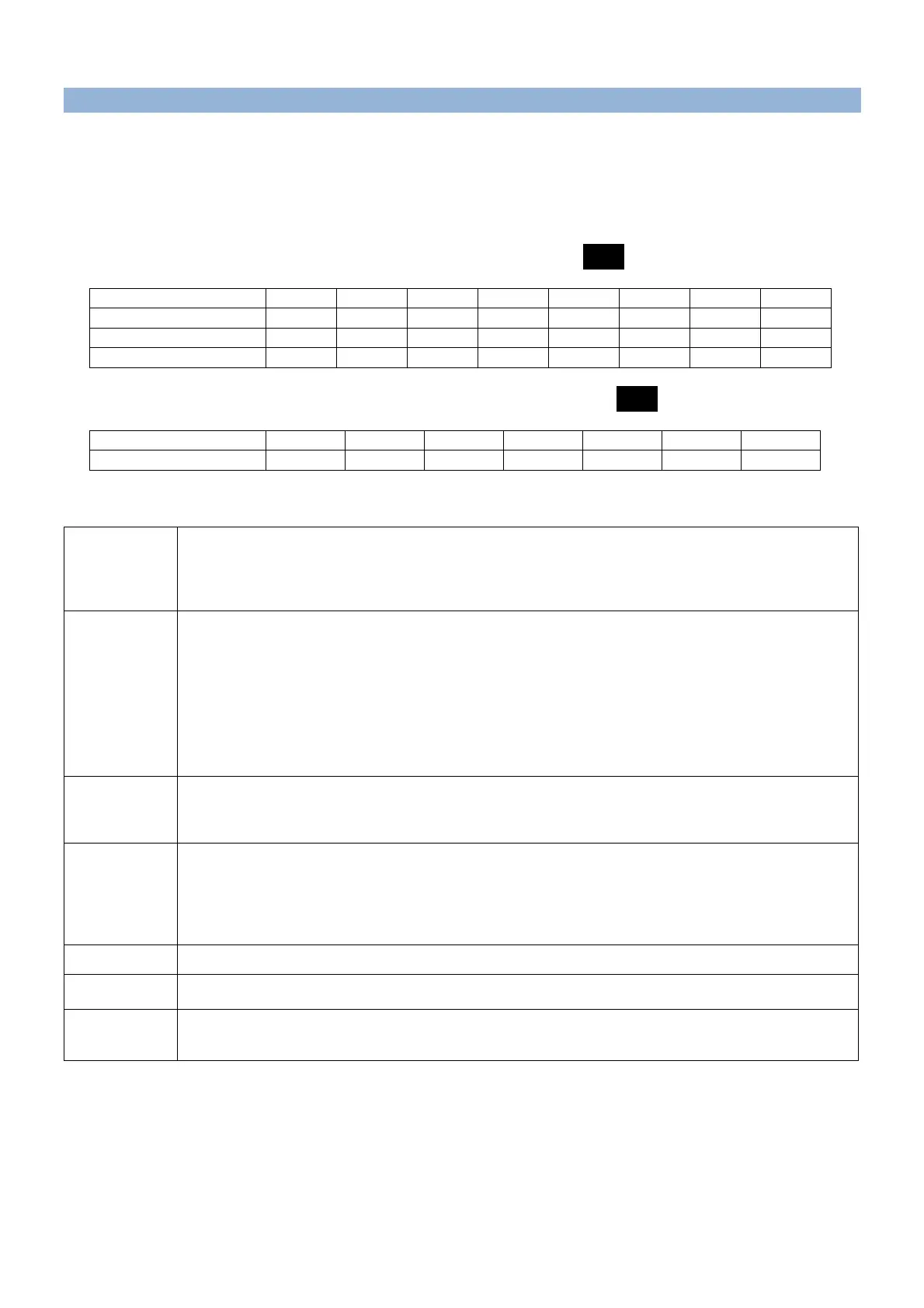

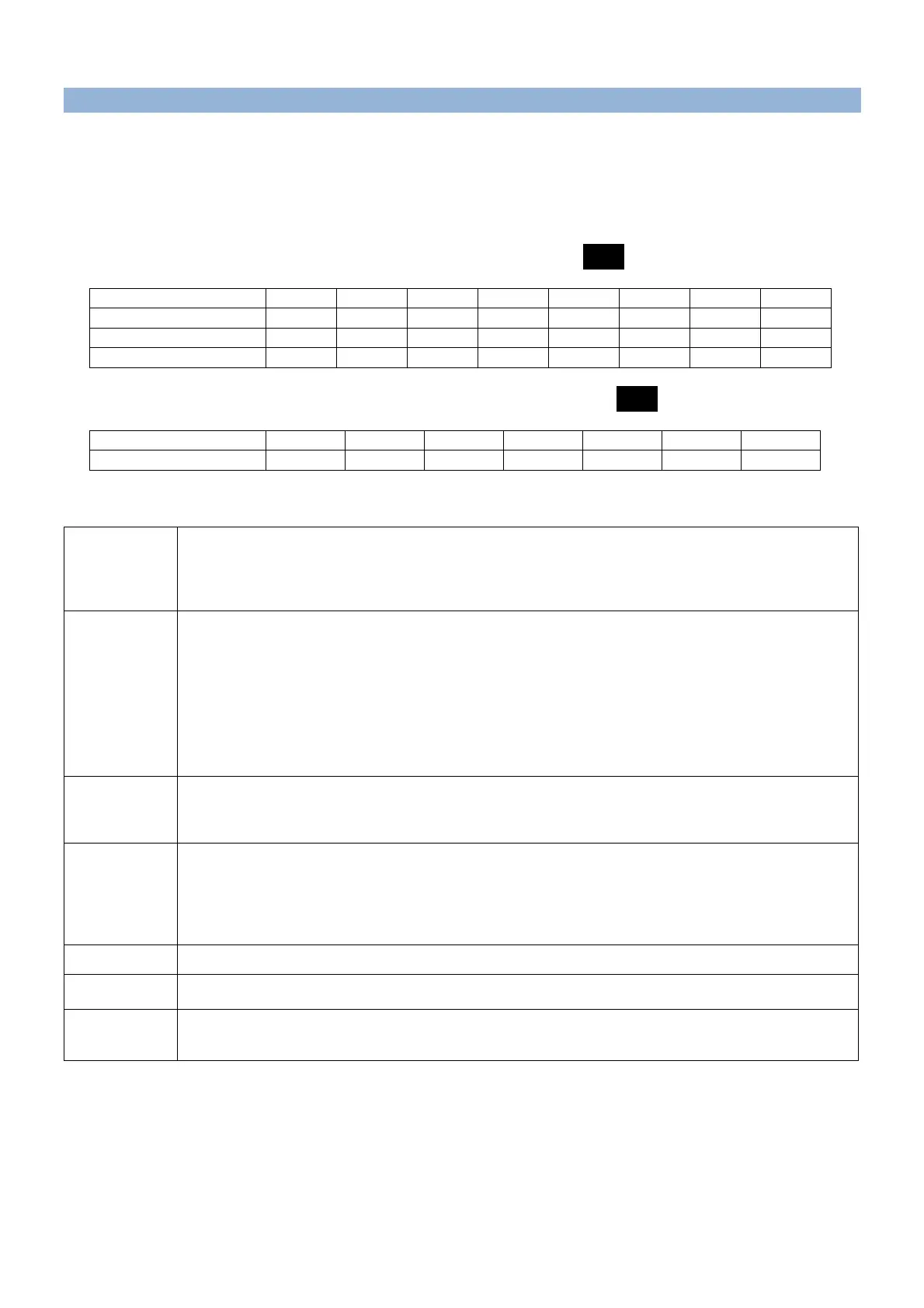

Service Road mode program (Abbreviation SEr)

Working hours 100 800 1600 2400 3200 4000 4800 5600

First check

Maintenance A

Maintenance B

Service stand-by mode program (Abbreviation SEe)

Working hours 1000 2000 3000 4000 5000 6000 7000

Maintenance E

and the list of controls:

FIRSTCHECK

• Check the compressor belt tension

• Check that there are no vibrations on the engine at low speed, and the compressor is set correctly

• Check the tightening torque of bolts and screws on the unit and the compressor kit

MAINTENANCE

A

• Cleaning of the condenser and evaporator

• Check the oil level in the stand-by compressor

• Check the defrost cycle and the efficiency of the condensate drain

• Clean the battery and its terminals

• Checking the refrigerant charge

• Checking the functions of cabin command

• Check and clean the electrical connections

• Check the tightening torque of bolts and screws on the unit and the compressor kit

• Replacement the drive belts

MAINTENANCE

B

• Replacement of the brushes of the electric motors in direct current and cleaning

• Check the bearings of the belt tensioners and bearings of the mechanical units

• Check the fans of condenser and evaporator

MAINTENANCE

E

• Check voltages and currents of the following components:

• transformer

• diode bridge

• AC motor

• Check and clean the electrical connections

• Check the value of the thermal relay F1T

Every6months

• Thoroughly clean the condenser

Everyyear

• Replace the filter dryer

• Check and clean the orifice of the thermostatic valve

Everytwo

years

• Change oil compressor (use only POE oil)

• Replace the refrigerant gas

• S

To ensure consistent performance of the machine, it is recommended to clean the condenser at least every six

months. This operation can be performed by compressed air (directed from the inside towards the outside), with

the help of a brush with soft bristles and taking care not to damage the fins. If the condenser presented residuals

removable with the operations described above, may be recommended her washing. A suitable product is the DEK

34 Alluter by Unison or equivalent. Always be sure to follow the specific instructions of the manufacturer.

Loading...

Loading...