Page 57

protection. Replace the logic board.

6. CHECK UP NEEDED

This is a warning. It is an information for the user that the programmed time for mainte-

nance is elapsed.

7. INCORRECT START

This alarm signals an incorrect starting sequence. Possible causes:

a. running microswitch failure;

b. error in sequence made by the operator;

c. incorrect wiring;

d. if the default persists, replace the logic.

8. FORW + BACK

The test is carried out continuously. An alarm is signalled when a double running re-

quest is made simultaneously. Possible causes:

a. defective wiring;

b. running microswitch failure;

c. incorrect operation;

d. if the defect persists, replace the logic.

9. HANDBRAKE

The truck does not start because the handbrake switch is opened. Possible causes:

a. defective wiring;

b. failure of the microswitch;

c. incorrect operation of the operator;

If the defect persist , replace the logic.

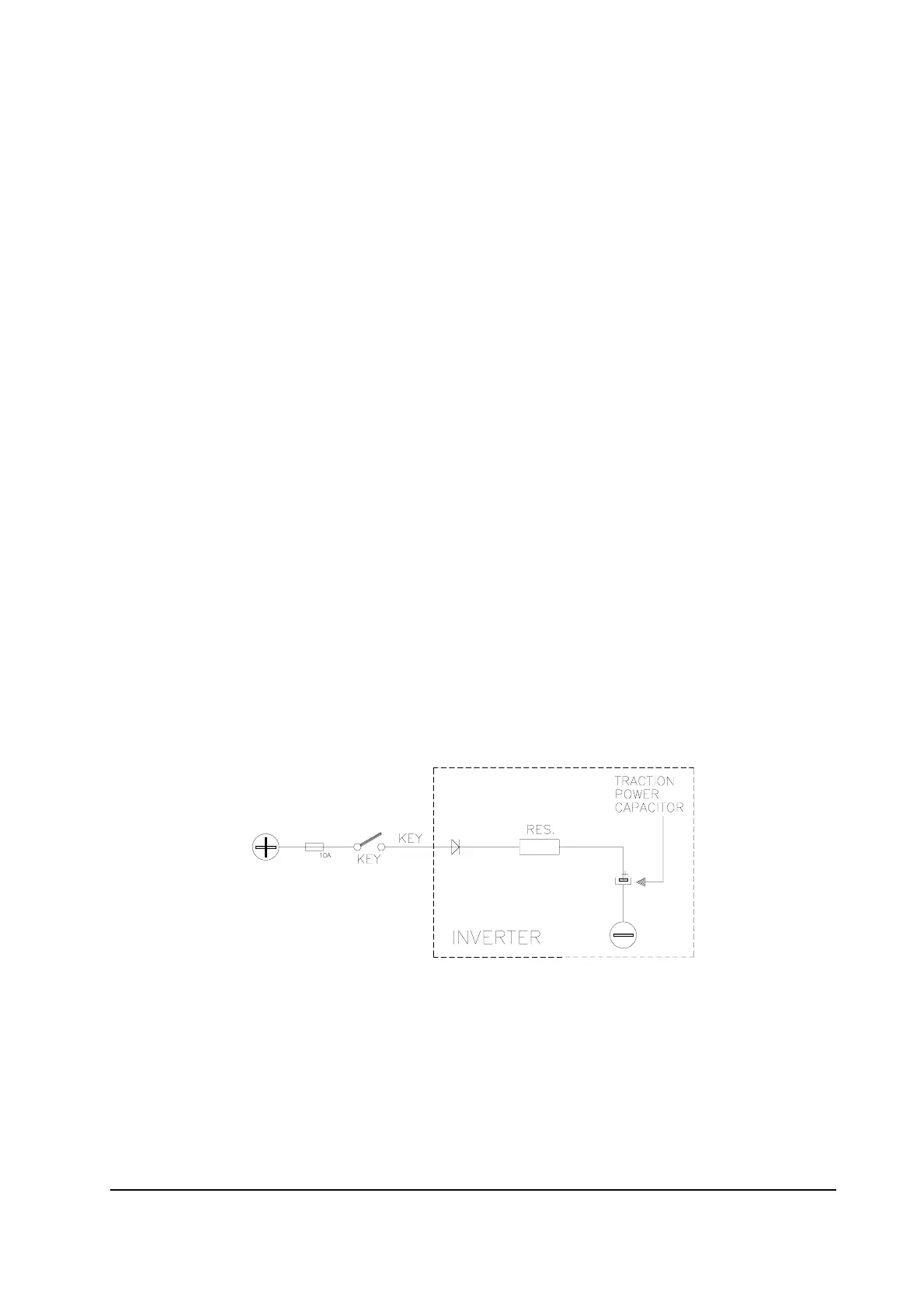

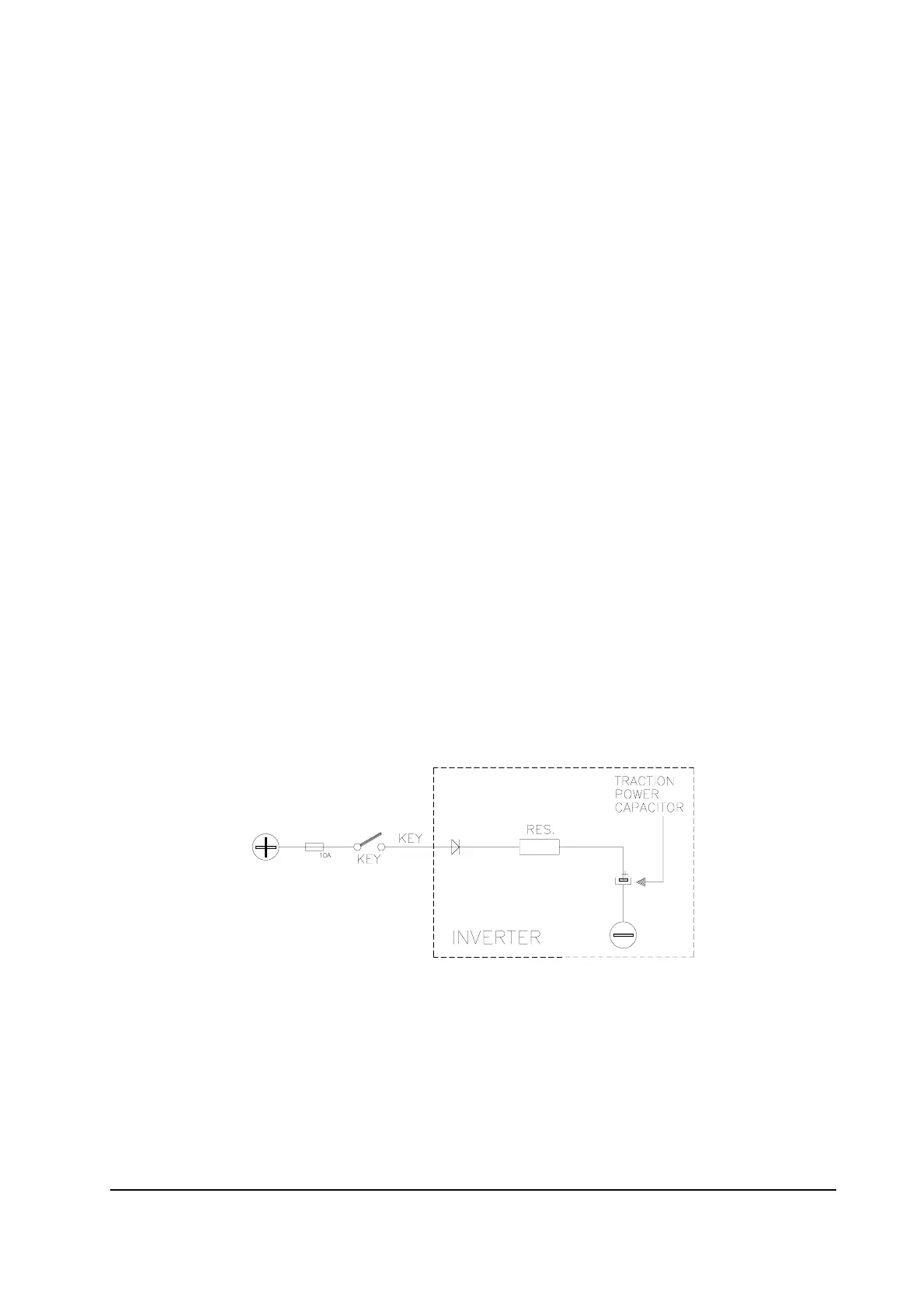

10. CAPACITOR CHARGE

Follows the charging capacitor system:

When the key is switched ON, the inverter tries to charge the capacitor through a power

resistance, and check if the capacitor are charged within a timeout. If this is not true: an

alarm is signalled; the main contactor is not closed.

Possible reasons:

a) the charging resistance is opened; if it is opened.

b) The charging circuit has a failure.

c) There is a problem on the power modules.

Loading...

Loading...