Supplemental Media Sensor Sensitivity Adjustment

Sometimes the standard procedure will not work with especially heavy media

backing material. In this case, the printer fails to calibrate, goes into PAUSE

mode, and the Paper/Ribbon light comes ON. If this happens, perform this

supplemental procedure. Make sure that you perform the regular procedure

BEFORE performing this procedure.

1. Remove the Electronics Cover to allow access to the Main Logic Board.

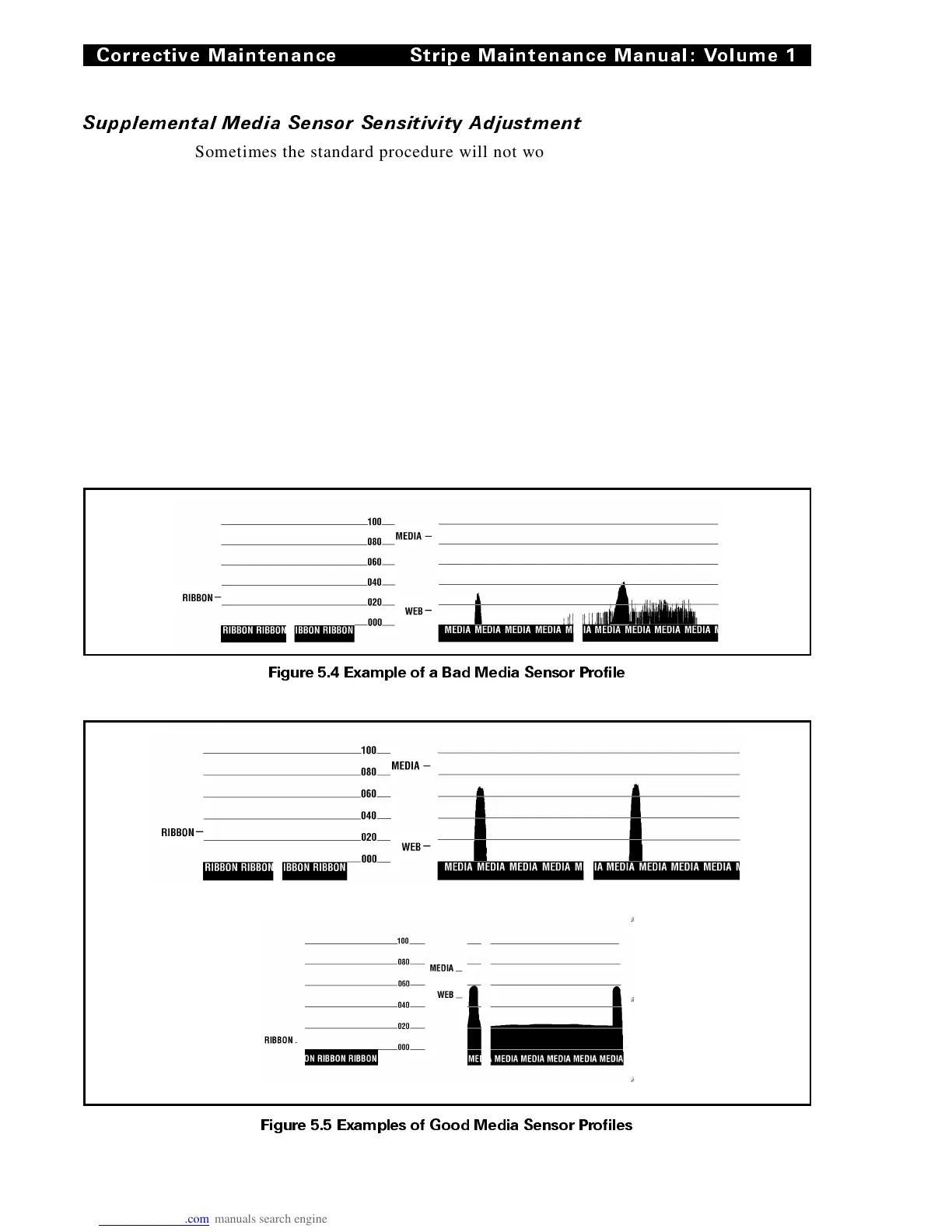

2. Print a Media Sensor Profile by pressing the Mode key once after the printer

completes the Power On Self Test. At this point, the Media Sensor Profile

will look something like the one shown in Figure 5.5.

3. As the Media Sensor Profile is printing, adjust the Media Sensor

Potentiometer while viewing the profile until the peak and the background

are distinctly separated (see Figure 5.5). If the peak is being printed in the

interlabel gap, view the resulting peak on the used ribbon instead.

4. Replace the Electronics Cover and reload ribbon and media.

5. Cycle power OFF then ON to resume printing.

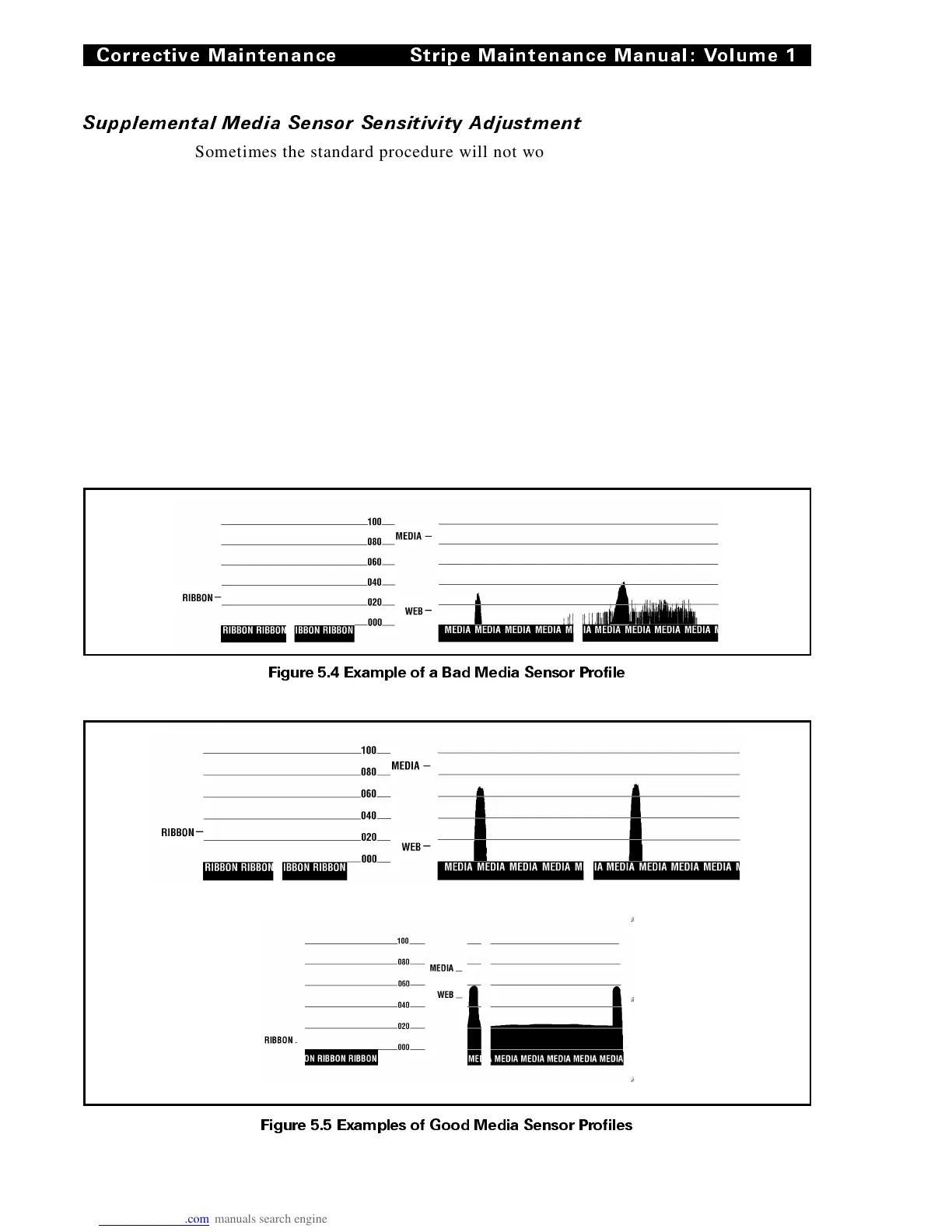

Figure 5.4 Example of a Bad Media S ensor P rofile

Figure 5. 5 Examp les of Good Media Sensor Profil es

Corrective Maintenance Stripe Maintenance Manual: Volume 1

Page 5-6 44868L

Loading...

Loading...