Motor Balance Procedure

A potentiometer (RV1) is mounted on the printer’s Power Supply Board that will

balance the current traveling to both phases of the stepper motor. Proper balance

of this current is essential in order to achieve optimum print quality and

minimize resonance.

1. Print at 2 inches/sec (Speed A).

2. Turn the potentiometer (RV1) until the printer is at minimum resonance. See

Figure 5.26. This minimum resonance point may be detected by ear or by

placing your hand on the printer. At this point the printer is approximately

balanced, it is now necessary to fine-tune this adjustment.

3. Print the following label format on the printer.

^XA ^PRA ^LHO, 20 ^FS

^F0190, 610 ^GB410, 0, 2 ^FS

^F0190, 615 ^GB410, 0, 2 ^FS

^F0190, 620 ^GB410, 0, 2 ^FS

^F0150, 730 ^GB490, 0, 2 ^FS

^F0150, 735 ^GB490, 0, 2 ^FS

^F0150, 740 ^GB490, 0, 2 ^FS

^F0110, 850 ^GB570, 0, 2 ^FS

^F0110, 855 ^GB570, 0, 2 ^FS

^F0110, 860 ^GB570, 0, 2 ^FS

^F070, 970 ^GB650, 0, 2 ^FS

^F070, 975 ^GB650, 0, 2 ^FS

^F070, 980 ^GB650, 0, 2 ^FS

^F030, 1090 ^GB730, 0, 2 ^FS

^F030, 1095 ^GB730, 0, 2 ^FS

^F030, 1100 ^GB730, 0, 2 ^FS

^PQ10 ^XZ

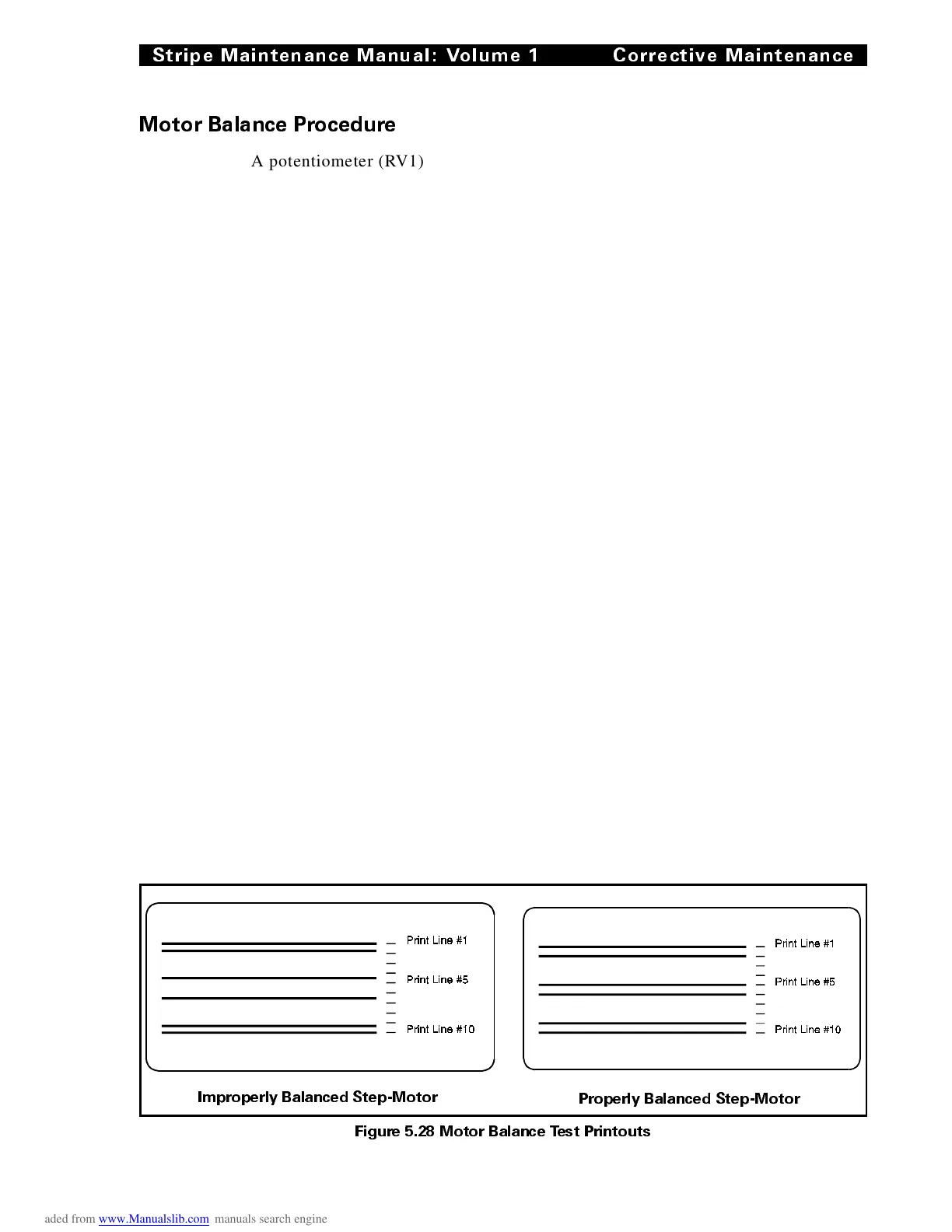

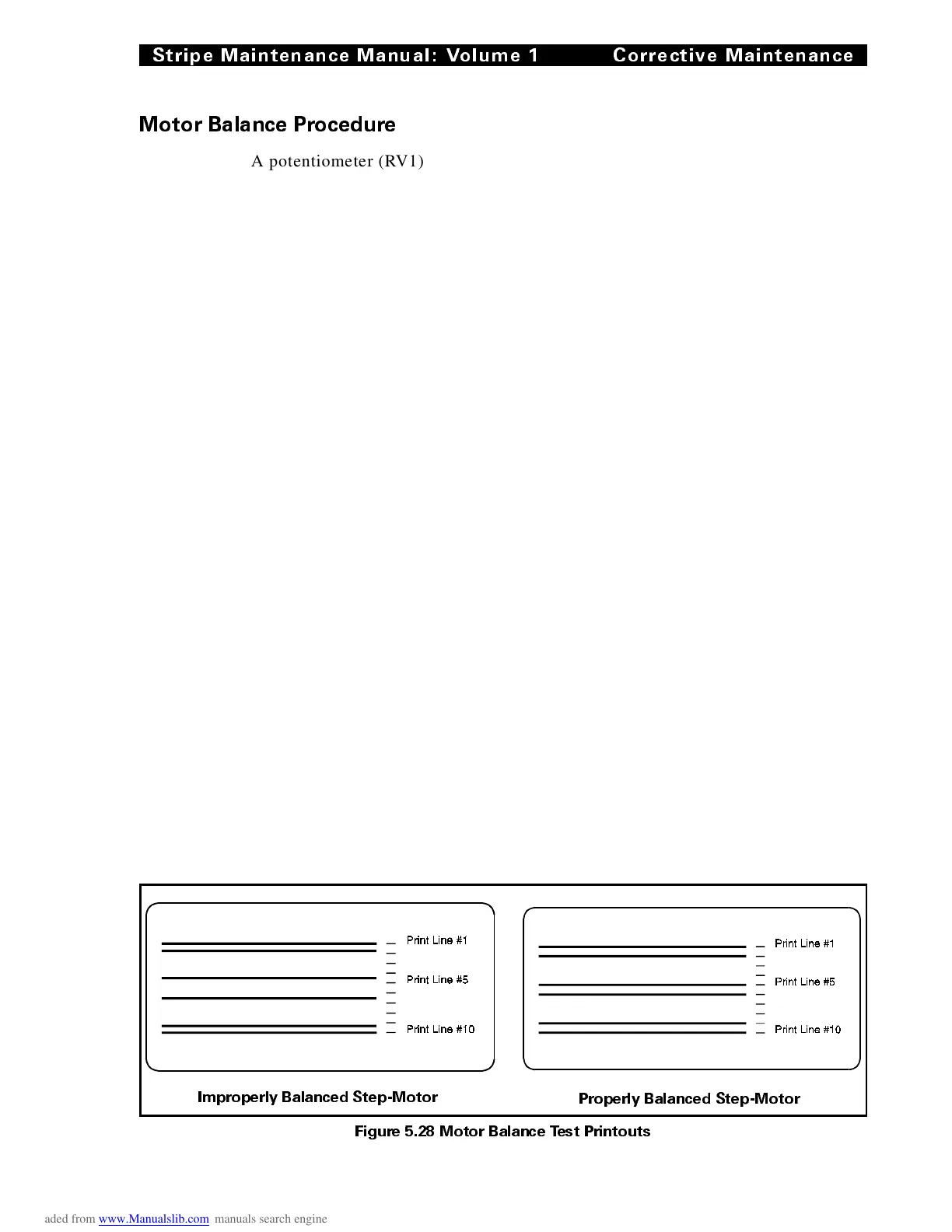

4. This label format consists of a horizontal line that is two dot rows thick

separated by 5 vertical dots. When the motor is not balanced, the angular

rotation that the motor rotates per step is not equal thus causing a large or

small step increment. An incorrect step size will cause the separation

between dot rows to be inconsistent which can be seen in Figure 5.12.

5. The motor potentiometer should be rotated until the label format approaches

the quality of the label found in Figure 5.27.

Figure 5.28 Motor Balance Te st Pri ntouts

Improperl y Bal anced Step-Motor

Properly Balanced Step-Motor

Stripe Maintenance Manual: Volume 1 Corrective Maintenance

44868L Page 5-39

Loading...

Loading...