ZEKS Eclipse

TM

90-5,000ZPB Desiccant Dryers

www.zeks.com

25

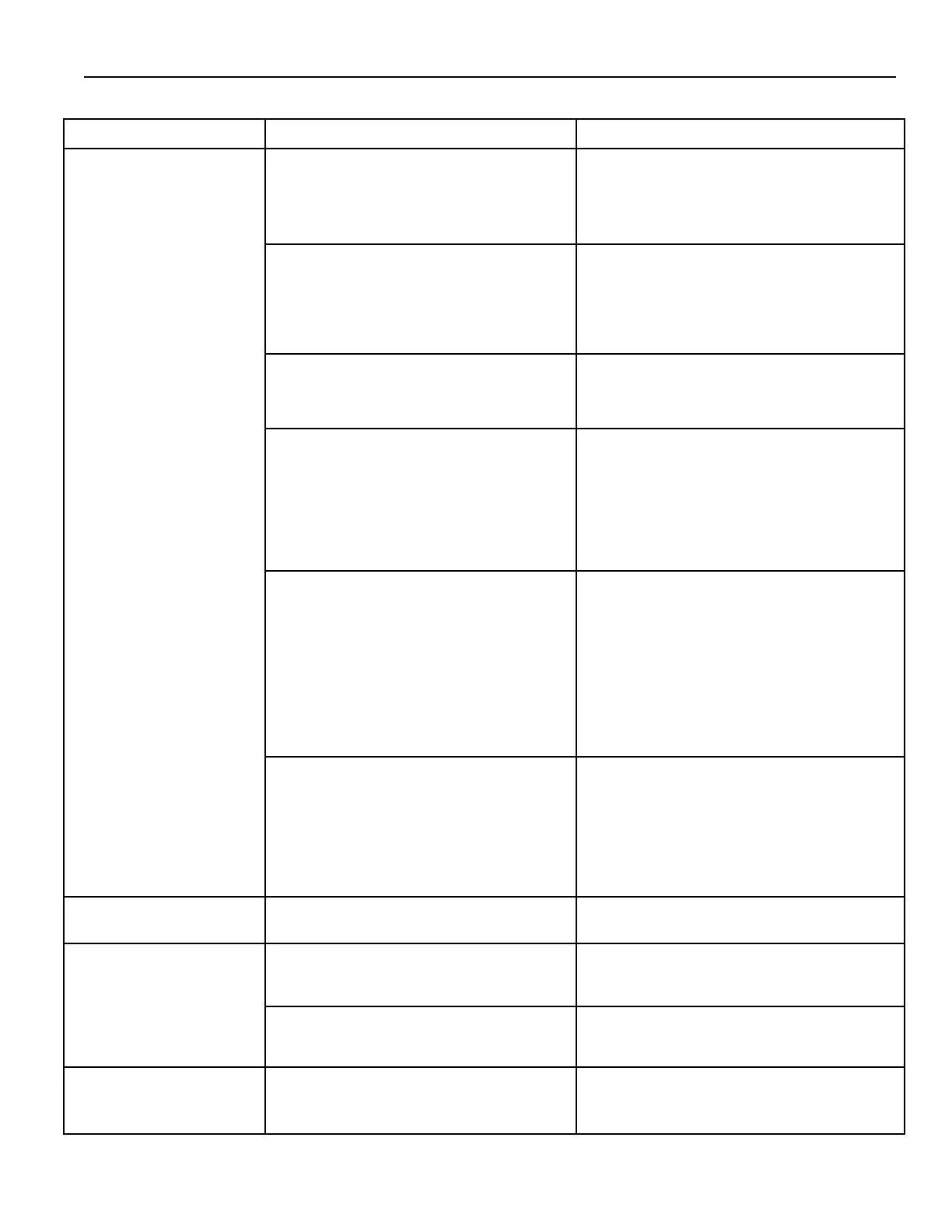

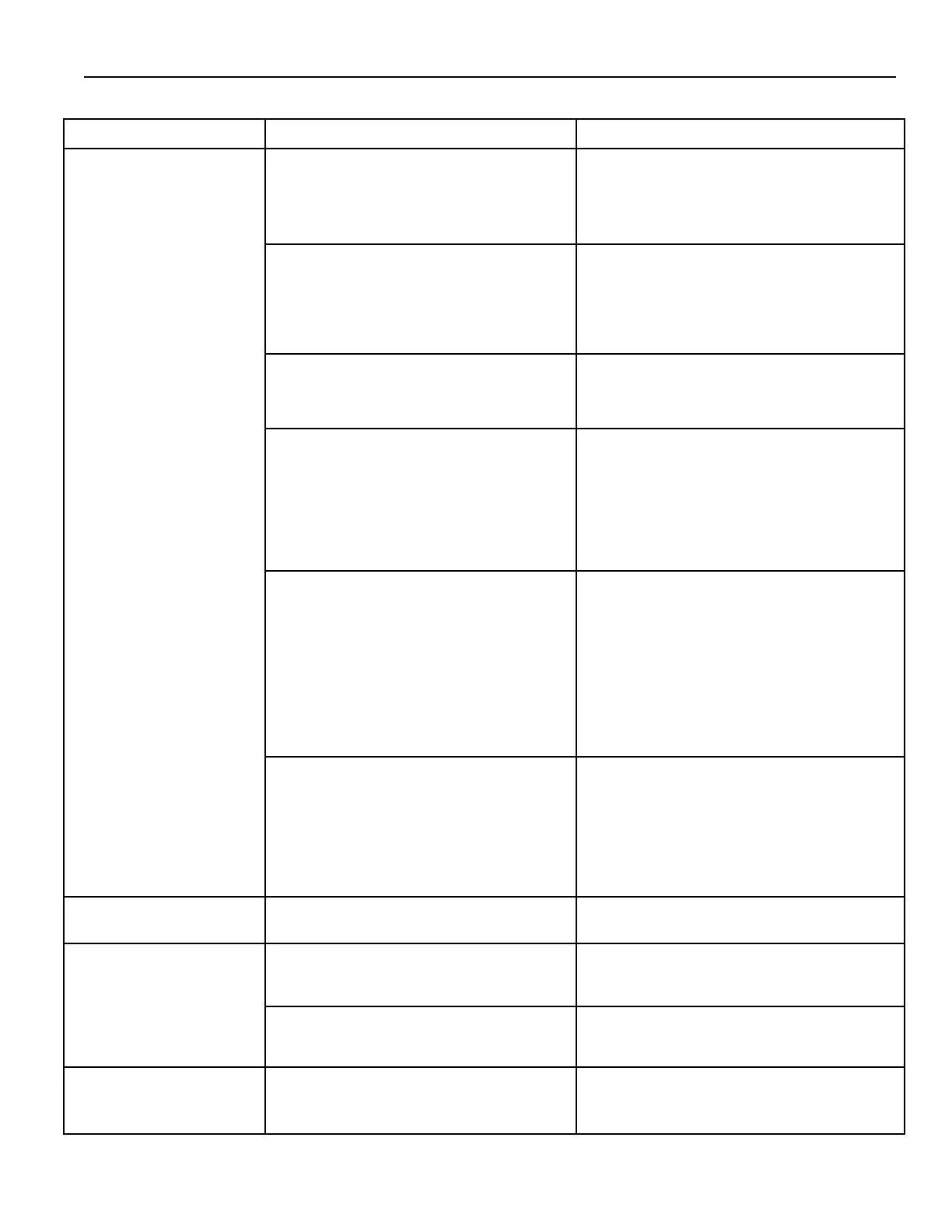

10.0 TROUBLESHOOTING

PROBLEM

Elevated Dew-point

Blue Moisture Indicator (BMI)

Turns Gray

Excessive Pressure in Tower

Designated For Regeneration

(Above 3 PSI)

Inability to Maintain Line

Pressure On Drying Tower

PROBABLE CAUSE

Insuffi cient purge fl ow

Improper valve operation

Inlet air pressure below design condition.

Flow rate is higher than design condition

Inlet temperature to the dryer exceeds the

rated capacity of the dryer.

Desiccant bed is fl ooded with moisture. The

BMI will turn gray when this occurs.

Indicator is saturated as a result of an

elevated dew point.

Purge Muffl er is clogged.

Air leak across Purge Muffl er.

Leaking Check Valve.

CORRECTIVE ACTION

• Check purge fl ow settings. Verify that purge

gauge is reading proper value.

• Inspect purge valve & control air solenoid valves

for proper operation.

• Inspect muffl ers for clogging.

• Verify operation of main fl ow and purge valves.

• Inspect control air solenoid valves for proper

operation.

• Verify check valves are maintaining desired

pressures by using jog and valve test functions.

Refer to valve test section.

• Check pressure source and inspect piping

system for leakages.

• Verify that the dryer was sized appropriately for

the operating conditions.

• Verify that compressor sizing is properly

matched to dryer capacity.

• For specialty systems where the outlet of the

dryer is piped to a booster compressor, verify

that the fl ow of the booster compressor is below

the rated capacity of the dryer. Excessive fl ow

will fl uidize desiccant bed and result in dusting

that will signifi cantly reduce performance.

• Inspect the air compressor after-cooler and

drain to ensure proper operation. After-cooler

may require cleaning in to operate properly.

• Verify the inlet temperature does not exceed

120oF under normal operating conditions.

For applications that approach 120oF on

a continuous basis, dryer sizing should be

reviewed prior to operation of the dryer. The

standard design is rated based on an inlet

condition of 100oF @ 100 PSI and will not

deliver proper performance if it is undersized.

• Verify that the air compressor after-cooler drain

and the pre-fi lter drain are functioning properly.

• The desiccant will become saturated if

compressed air is permitted to fl ow through the

dryer before it is operating.

• If this occurs, the performance of the dryer will

not easily recover and this will void the warranty

on the desiccant material.

Refer to elevated dew-point corrective actions

listed above.

Inspect purge muffl ers for clogging and replace

as required. Follow proper safety precautions

during this process.

Determine if Inlet Valves and Outlet Check Valves

are functioning properly. Refer to valve test

section.

Utilize valve test function to determine if inlet and

outlet valves are functioning properly (NEMA 4

models only).

For Troubleshooting Procedures, refer to maintenance descriptions in SECTION 9 as required.

Loading...

Loading...