hitting each stave a little harder now as the bottom strap is

tightened. Don’t be afraid to hit pretty hard. Continue

tightening with wrench. At this point using the mirror,

any gaps should be virtually gone. If not, stop, back up a

few steps – loosen the straps a bit and distribute the gap

as described earlier.

Now do a final tightening - but don’t overdo it. The

bottom strap is pressing against the floor on the inside, so

it will reach a point where you can tell it is tight - don’t

force it beyond that. Use vise grip pliers to clamp onto

the aluminum block that the bolt passes through to keep it

from twisting as you do the final tightening. Stop when

you see noticeable deflection of the aluminum blocks.

This indicates bottom strap is tight enough.

The upper

straps don’t need to be as tight as the bottom. If it feels

tight, it is. Do a final adjustment on the top of the staves

at this time. Remember - the wood will swell to tighten

all joints further once water is introduced.

TIP: If you have a torque wrench – the bottom strap

should be tightened to about 40 lbs. of torque (similar to

a lug nut on a vehicle), the upper ones to a lesser amount

- about 25 lbs. of torque.

Next climb inside the tub and remove the temporary floor

braces. With a tube of clear silicone caulk, place a very

small (1/4”) neat bead all around the inside corner where

the floor and the staves meet. Use your finger or a

rounded piece of wood like a tongue depressor to smooth

the bead. Also put a very small bead on the top of the

floor seam. The purpose of the silicone is to slow the

initial seepage from the dry tub - allowing the wood to

absorb more water and swell more quickly. Your tub will

hold water as a result of the expansion of the wood,

causing the joints to compress.

Your tub is now ready for installation of the heating

system and any other accessories.

Section 9: Accessories

Install any accessories in this order:

1. Heating system - see separate instructions for

your type of heater

2. Benches - see below

3. Tub Shelf

4. Access Steps - see below

5. Cover - see below

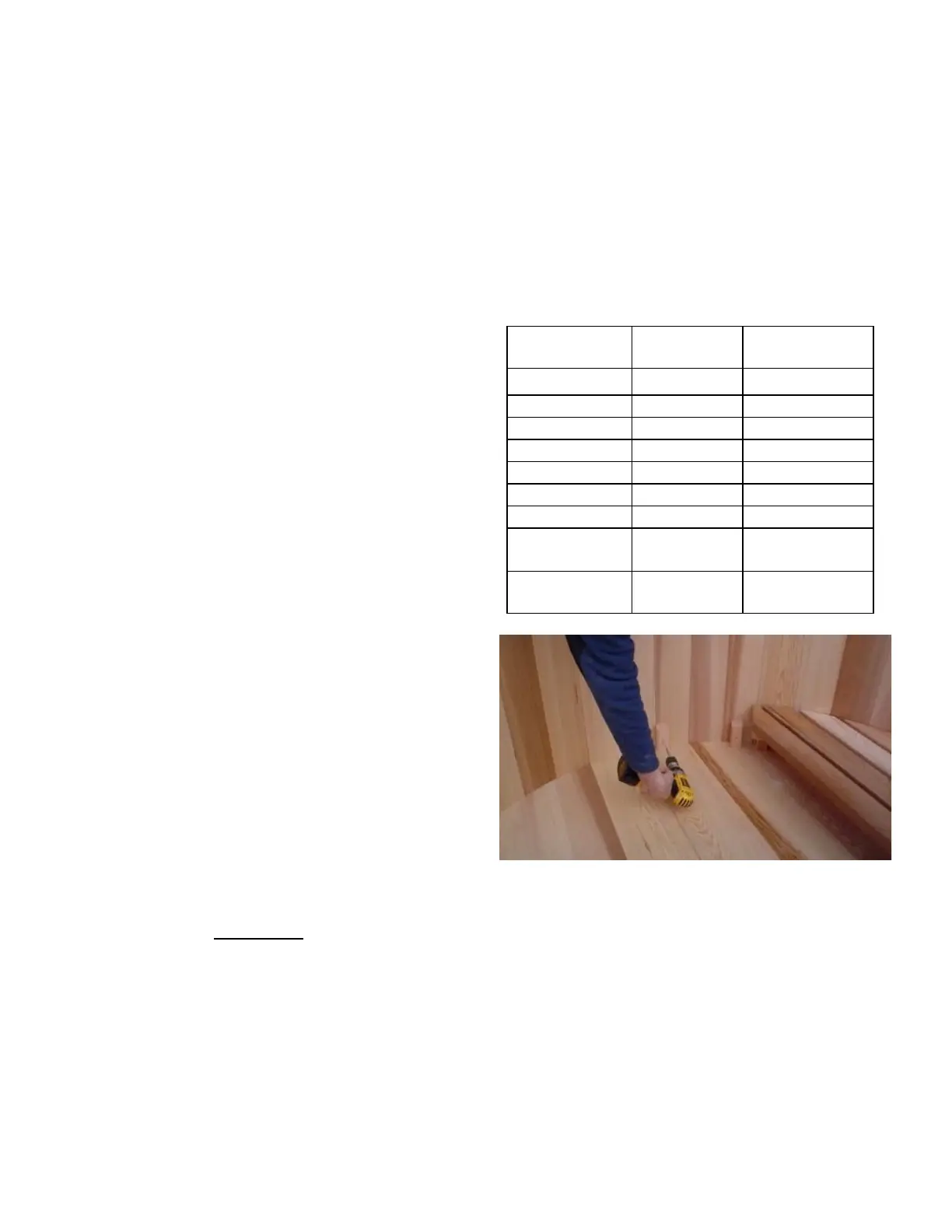

Figure 9.2 Aligning and attaching bench blocks – DO

NOT drive a screw into a seam between staves! This will

cause a leak.

A bench is typically held in place with four blocks, which

act as legs, which are screwed directly to the inside of the

staves with the included 3” stainless screws. The bench is

then screwed down to the top of those four blocks with 3”

deck screws. Place the blocks so you can screw down

through the bench frame between the slats and into the

top of the blocks. Place the benches so the drain is

accessible. See Figure 4.3 for typical orientation of

Loading...

Loading...