8. Maintenance

IMPORTANT

• Notethatusinganysparkplugotherthanthosedes-

ignated may result in the engine failing to operate

properly or in the engine becoming overheated and

damaged.

• Toinstallthesparkplug,rstturnthepluguntilitis

finger tight, then tighten it a quarter turn more with a

socket wrench.

Tightning torque:

9.8~11.8N.m.

(1.0~1.2kgm)

■ GEAR CASE

• Thereductiongearsarelubricatedbymultipurpose,

lithium-based grease in the gear case. Supply new

grease every 25 hours of use or more often depend-

ing on the job condition.

• Removetheboltopposittothegreasenipplebefore

installing new grease to arrange for old grease to exit.

WARNING

Makesurethattheenginehasstoppedandiscool

beforeperforminganyservicetothemachine.Con-

tactwith moving cuttingheador hot mufermay

resultinapersonalinjury.

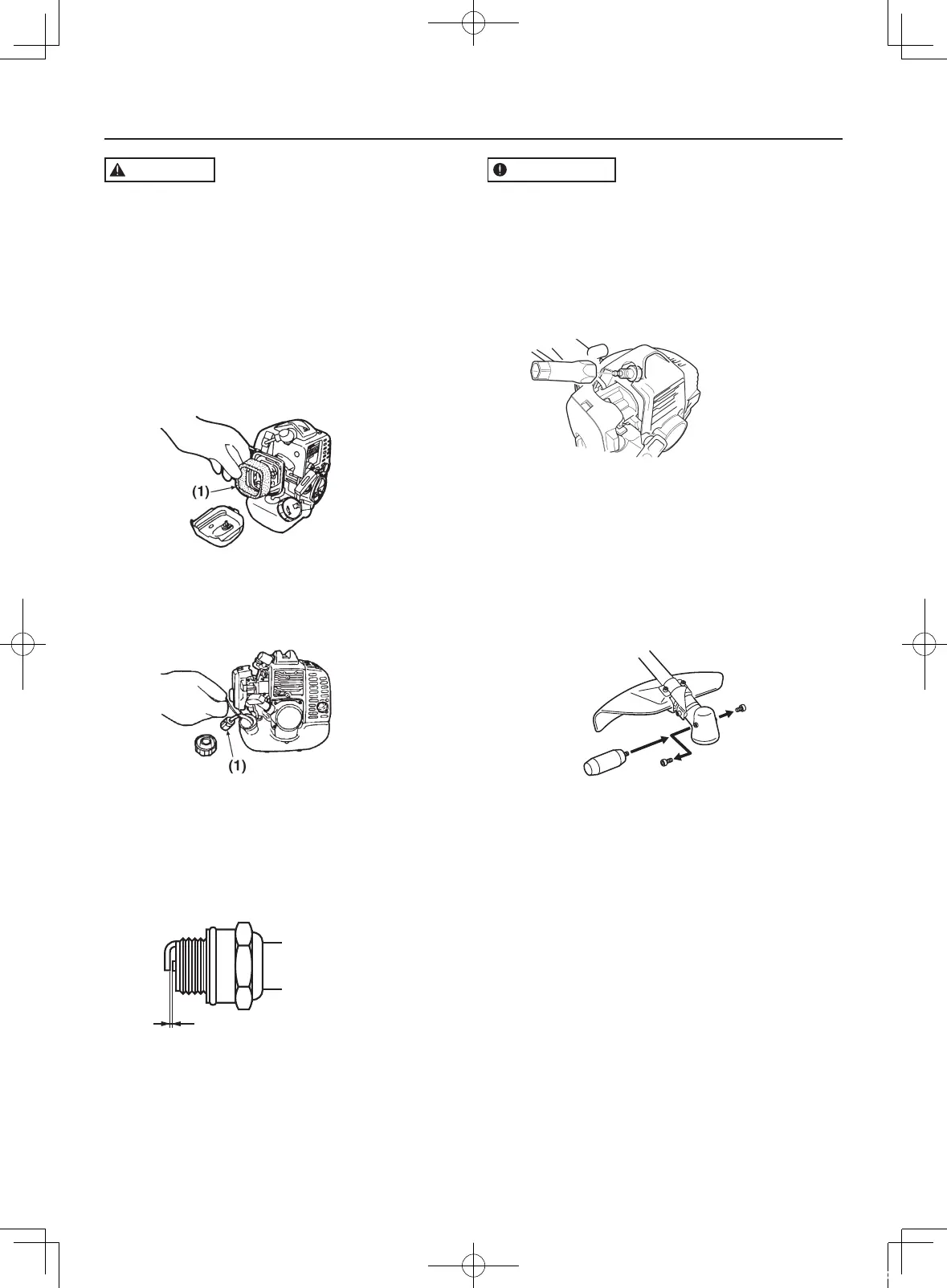

■ AIR FILTER

The air filter, if clogged, will reduce the engine perfor-

mance. Check and clean the filter element in warm,

soapy water as required. Dry completely before installing.

If the element is broken or shrunk, replace with a new

one.

(1) Air filter

■ FUEL FILTER

When the engine runs short of fuel supply, check the fuel

strainer for blockage.

(1) Fuel strainer

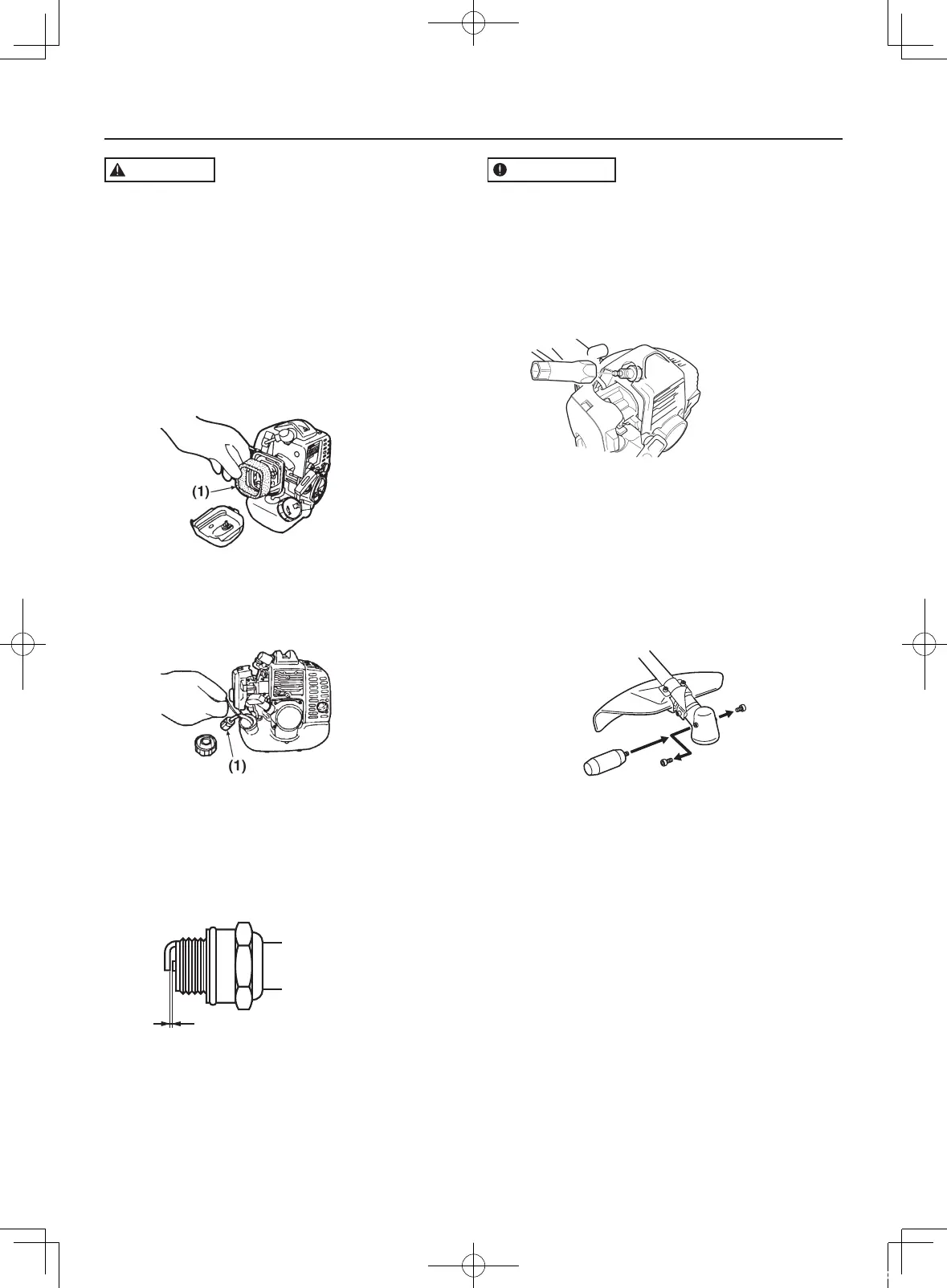

■ SPARK PLUG

Starting failure and misfiring are often caused by a fouled

spark plug. Clean the spark plug and check that the plug

gap is in the correct range. For a replacement plug, use

the correct type specified by ZENOAH.

0.6~0.7mm

REPLACEMENT PLUG IS

A NGK BPMR7A.

GB-12

BC3450DW / BC4350DW

BC3450DW_4350DW_GB_cs5.indd 12 17/09/05 17:04

Loading...

Loading...