REFRIGERATION

GENERAL

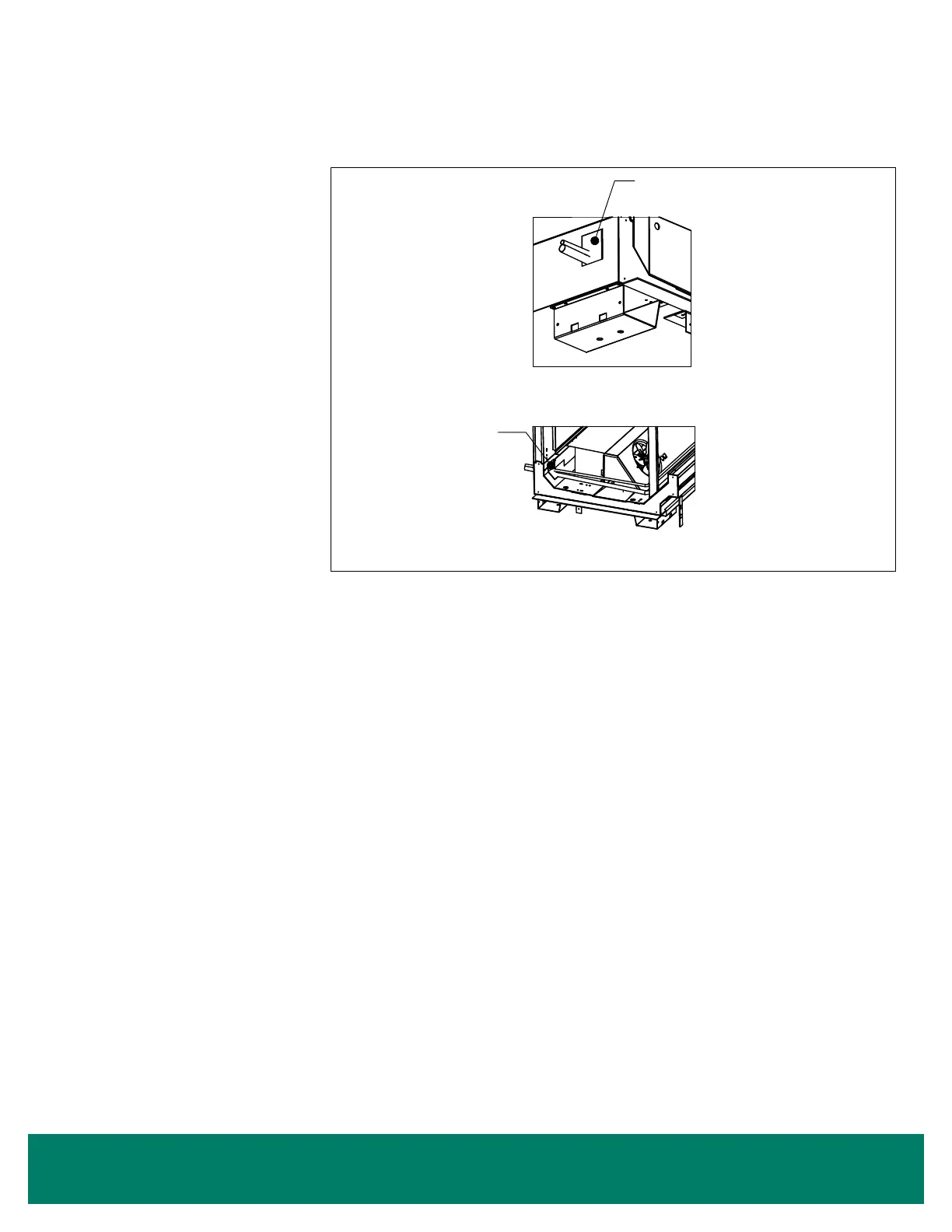

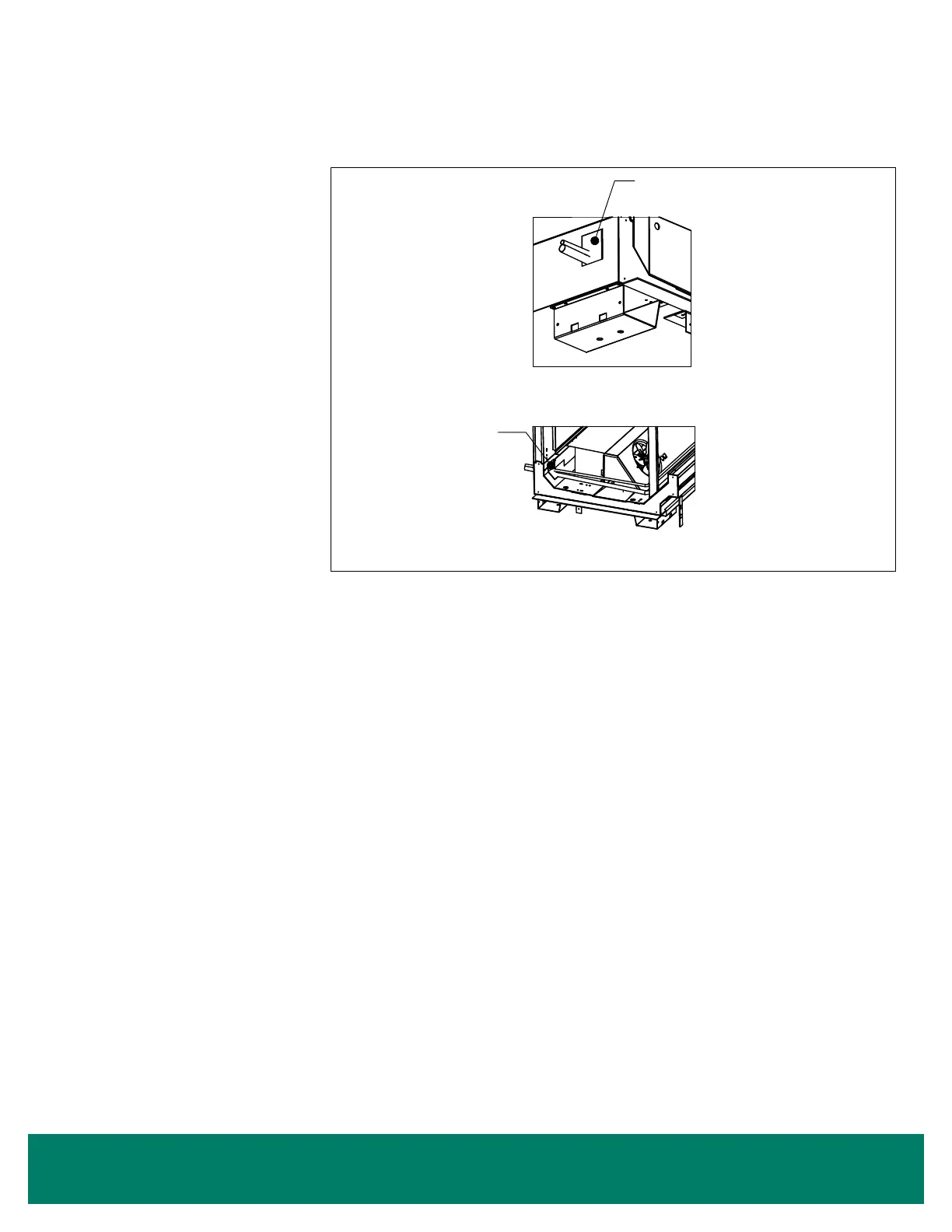

Unless otherwise specied, the liquid

and suction connections are made

inside the case under the evaporator

fan/coil cover. Refrigerant piping

may enter the case through the front

left bottom, the left rear bottom of

case, or the left rear top of case.

The copper pipe should not touch or

rub on the edges of the sheet metal.

After connections have been made,

the refrigeration access hole in the

case must be sealed completely

with an aerosol-dispensed Urethane

insulation or equivalent (i.e. Great

Stuff). Penetrations made in sheet

metal bafes should also be sealed

(Figure 19).

REFRIGERANT PIPING

Correct refrigeration line sizing and installation is essential for proper system operation. Figure 23 on page 26, Figure 24 on page

27, and Figure 25 on page 28 are for Evolution (V) model cases. Contact the factory for line sizing for the Maximizer (M) model

cases. A P-trap must be installed at the bottom of all vertical suction risers (Figure 20 on page 24). Various risers are available as a

factory installed option.

When two or more case sections are connected to one compressor, the main liquid and suction line for the group should be run through

the cases and be brought out through the refrigeration outlet of one case only. The factory recommends one riser per circuit/system for

hot gas defrost when using top back refrigeration exit. Circuit risers are available as a factory installed option. On 30" wide door cases

with suction lines over 1 3/8" diameter, a P-trap made with 45° elbows is required (Figure 20 on page 24). A piping chase in front of

the fan shroud allows the refrigerant lines to be run through the right or left end frame.

Piping should not be placed near the electric defrost heaters. The defrost heaters on the 30" door cases will grow one inch to the left of

the coil when they reach operating temperature.

The compressor should be installed as close as possible to the cases to reduce pressure drop. Install a shallow trap at the bottom of the

riser.

The best location for the liquid line drier is inside the case compartment. However, it may be installed near the compressor for easy

maintenance. Install moisture indicating sight glass at the outlet end of the drier.

A low pressure or temperature control can be used to control case temperature. The control should be selected with adequate contact

capacity for the switching load. In rack systems, an evaporator pressure-regulating valve may be used to control the evaporating

temperature.

The settings (Figure 21 on page 25) are approximate due to variations in gauge accuracy, differences in compressor efciency, line

pressure drop and superheat settings. Before making adjustments for store or stocking conditions, make sure the superheat is set.

Close coupled systems typically run at the higher end of this range to avoid ood back.

Figure 19: Penetration Sealing

DWG. NO. SP-6007-1 REV. A

Fill in area with

foam after

installation

9561

9/20/2012

SHEET

SPECIFIED, ALL DIMENSIONS

(PER SP-0457)

INITIAL RELEASE

A

STANDARD

RELEASED

TOLERANCES:

CS

No. REVISION DESCRIPTION

ECN No.

PART WEIGHT:

NO MANUAL REVISIONS

CONSENT OF ZERO ZONE, INC. IS STRICTLY PROHIBITED.

(IN LBS)

CAD DRAWING

NONE

FINISH:

(PER SP-0404)

REPRODUCTION OR OTHER MEANS, WITHOUT THE WRITTEN

(PER SP-0154)

MATERIAL:

SIZE

NOT TO SCALE

Chris Standlee

SCALE:

(UNLESS OTHERWISE SPECIFIED)

REVISION

ZERO ZONE, INC.

DOCUMENT OR DISCLOSURE OF ITS CONTENTS; BY

ARE IN DECIMAL INCH

9/20/2012

A

1 OF 1

SP-6007-1

PENETRATION SEALING

SHEET:DATE:

A

MODELED BY:

DRAWN BY:

UNLESS OTHERWISE

USA 53153

DRAWING No:

DESCRIPTION:

BY

DATE

COPYRIGHT INFORMATION

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN, IS

THE SOLE PROPERTY OF ZERO ZONE, INC. ANY USE OF THIS

110 NORTH OAKRIDGE DRIVE

NORTH PRAIRIE, WISCONSIN

REVISION INFORMATION

Fill in area with

foam after

installation

Refrigeration - General • 23

Loading...

Loading...